A kind of degradable sugarcane pulp tableware and preparation method thereof

A technology for sugarcane pulp and tableware, which is applied in the fields of natural cellulose pulp/paper, non-woody plant/crop pulp, papermaking, etc., can solve the problems of products that do not meet hygienic requirements, poor anti-leakage effect, and low structural strength. , to achieve the effect of improving anti-leakage and high temperature resistance, reducing processing procedures, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

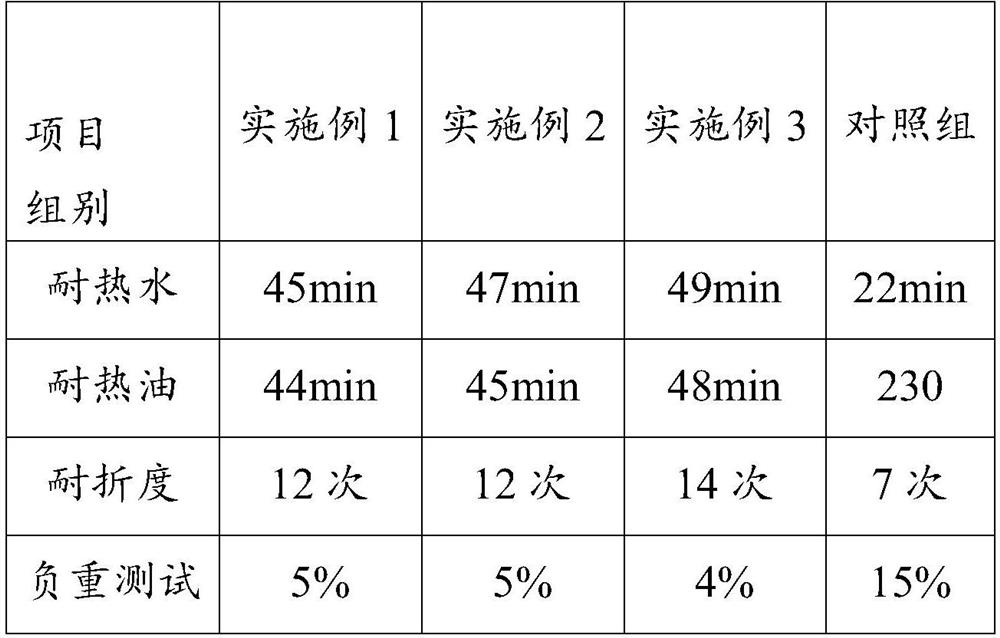

Embodiment 1

[0023] A kind of degradable sugarcane pulp tableware provided by the present invention is characterized in that it is made of the following materials in terms of mass percentage: 68 parts of sugarcane pulp paper, 28 parts of bamboo pulp paper and 3 parts of waterproofing agent, and the waterproofing agent is made of agar , propylene glycol alginate, beeswax, xanthan gum and chitin, the mass ratio of the agar, propylene glycol alginate, beeswax, xanthan gum and chitin is 2:5:7:5:3.

[0024] The preparation method of the tableware comprises the following steps:

[0025] S1. Put sugarcane pulp paper and bamboo pulp paper as raw materials into the pulper, inject clean water into the pulper, the mass ratio of clean water to raw materials is 7:1, let stand for 15-20min, and then adjust the crushing of the pulper The rotation speed is 200-600r / min, the time is 10-15min, and ozone is injected into the inside of the pulper for sterilization during the pulverization process, and the ori...

Embodiment 2

[0031] A kind of degradable sugarcane pulp tableware provided by the present invention is characterized in that it is made of the following materials in terms of mass percentage: 70 parts of sugarcane pulp paper, 30 parts of bamboo pulp paper and 4 parts of waterproofing agent, and the waterproofing agent is made of agar , propylene glycol alginate, beeswax, xanthan gum and chitin, the mass ratio of the agar, propylene glycol alginate, beeswax, xanthan gum and chitin is 2:5:7:5:3.

[0032] The preparation method of the tableware comprises the following steps:

[0033] S1. Put sugarcane pulp paper and bamboo pulp paper as raw materials into the pulper, inject clean water into the pulper, the mass ratio of clean water to raw materials is 7:1, let stand for 15-20min, and then adjust the crushing of the pulper The rotation speed is 200-600r / min, the time is 10-15min, and ozone is injected into the inside of the pulper for sterilization during the pulverization process, and the ori...

Embodiment 3

[0039] A kind of degradable sugarcane pulp tableware provided by the present invention is characterized in that it is made of the following materials by mass percentage: 72 parts of sugarcane pulp paper, 30 parts of bamboo pulp paper and 5 parts of waterproofing agent, and the waterproofing agent is made of agar , propylene glycol alginate, beeswax, xanthan gum and chitin, the mass ratio of the agar, propylene glycol alginate, beeswax, xanthan gum and chitin is 2:5:7:5:3.

[0040] The preparation method of the tableware comprises the following steps:

[0041] S1. Put sugarcane pulp paper and bamboo pulp paper as raw materials into the pulper, inject clean water into the pulper, the mass ratio of clean water to raw materials is 7:1, let stand for 15-20min, and then adjust the crushing of the pulper The rotation speed is 200-600r / min, the time is 10-15min, and ozone is injected into the inside of the pulper for sterilization during the pulverization process, and the original slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com