Optical glass

A kind of optical glass and glass technology, applied in optics, optical components, instruments, etc., can solve problems such as high cost, devitrification, and decreased glass stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

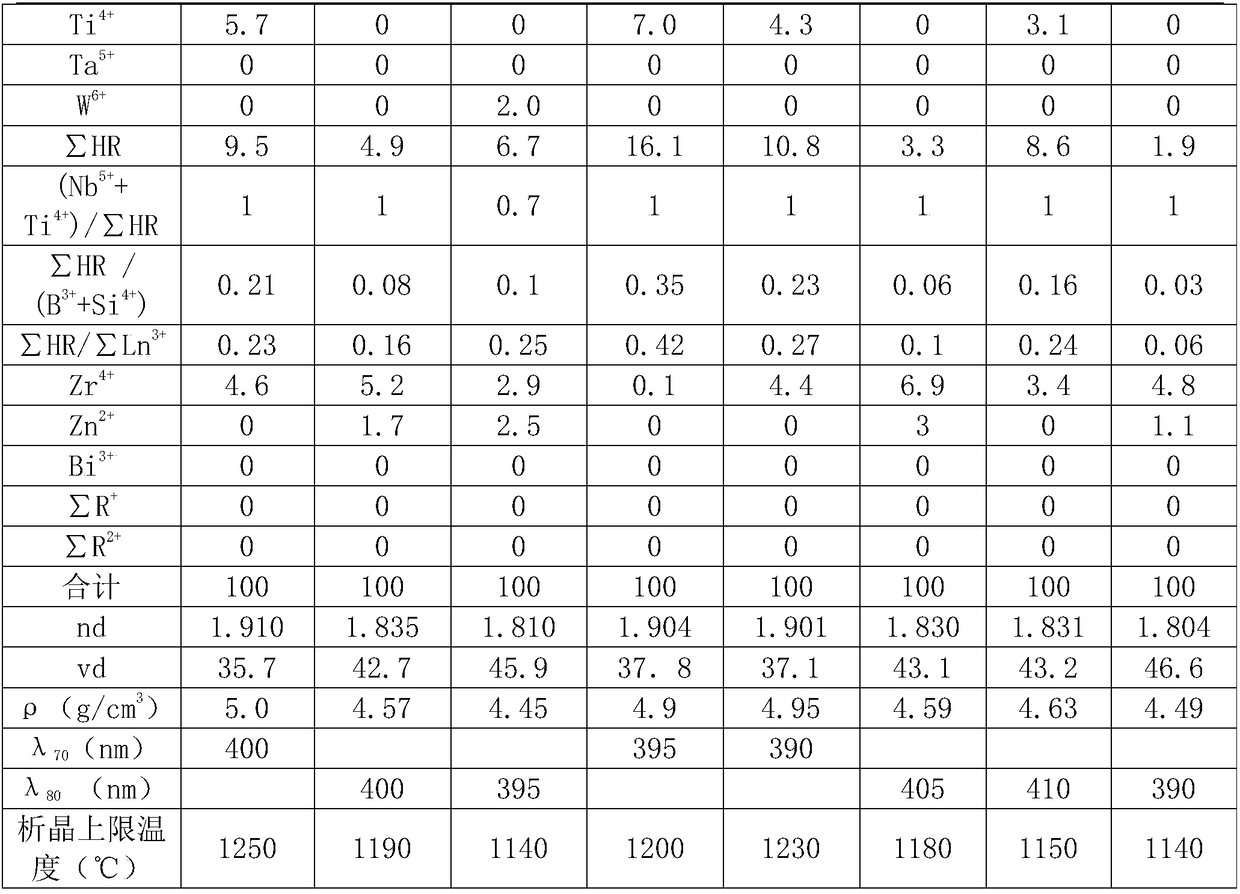

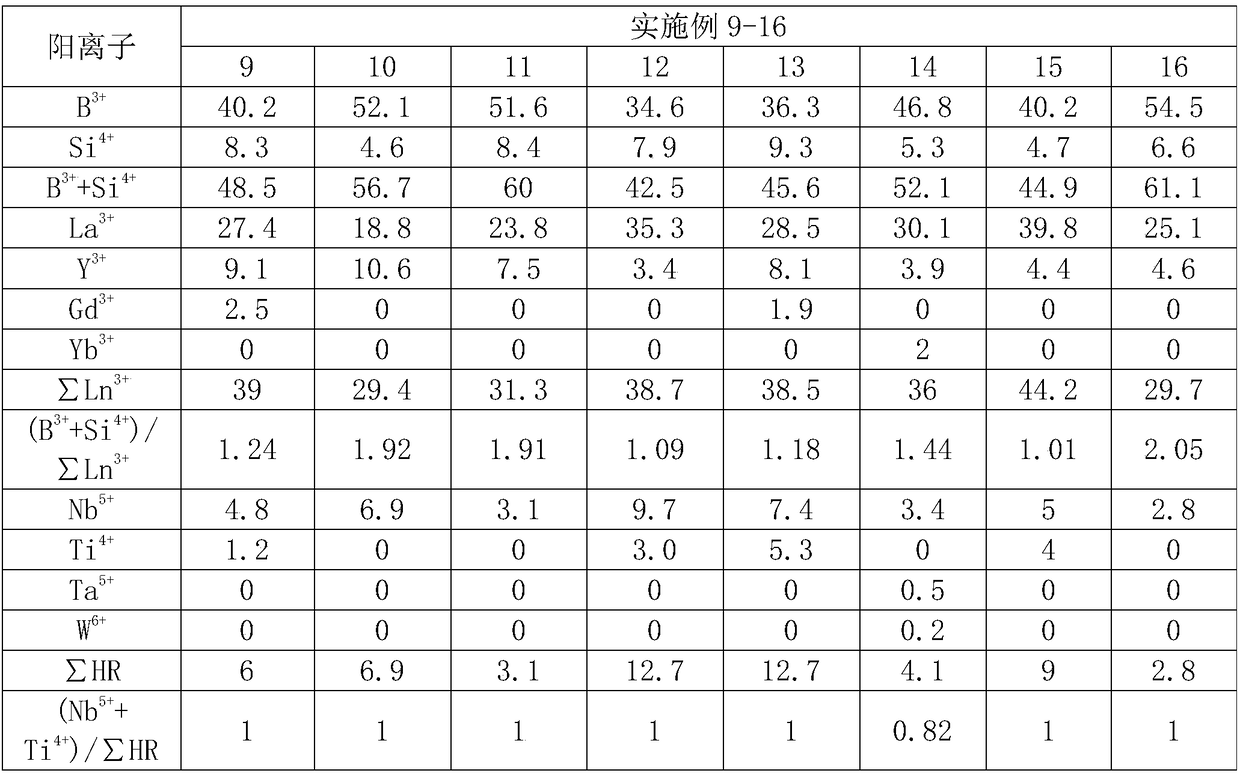

[0089] The technical solution of the present invention will be further described in detail through examples below, but the present invention is not limited by these examples. The optical glass of the present invention can be obtained by applying the method of adjusting the content of each glass component described above with reference to the following examples.

[0090] First, in order to obtain oxide glasses having the compositions (indicated by % of cations) shown in Tables 1 to 9, raw materials such as nitrates, carbonates, sulfates, hydroxides, oxides, and boric acid were used, and each glass was weighed. The raw material powder is fully mixed to become a blended raw material, which is put into a platinum crucible and heated, melted, clarified, and stirred at 1300-1450°C to become a uniform molten glass. The molten glass was poured into a preheated mold, rapidly cooled, kept at a temperature near the glass transition temperature for two hours, and then slowly cooled to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com