Valve type expanding head anchor rod bearing body

An enlarged head and valve type technology, applied in the installation of bolts, sheet pile walls, mining equipment, etc., can solve problems such as insufficient pull-out resistance, achieve low installation resistance, improve pull-out bearing capacity, and highlight substantive features Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The substantive content of the present invention is further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto. Although the present invention has been described in detail with reference to preferred embodiments, those skilled in the art should understand that the technical solutions of the present invention can be modified or equivalently replaced without departing from the spirit and scope of the technical solutions of the present invention.

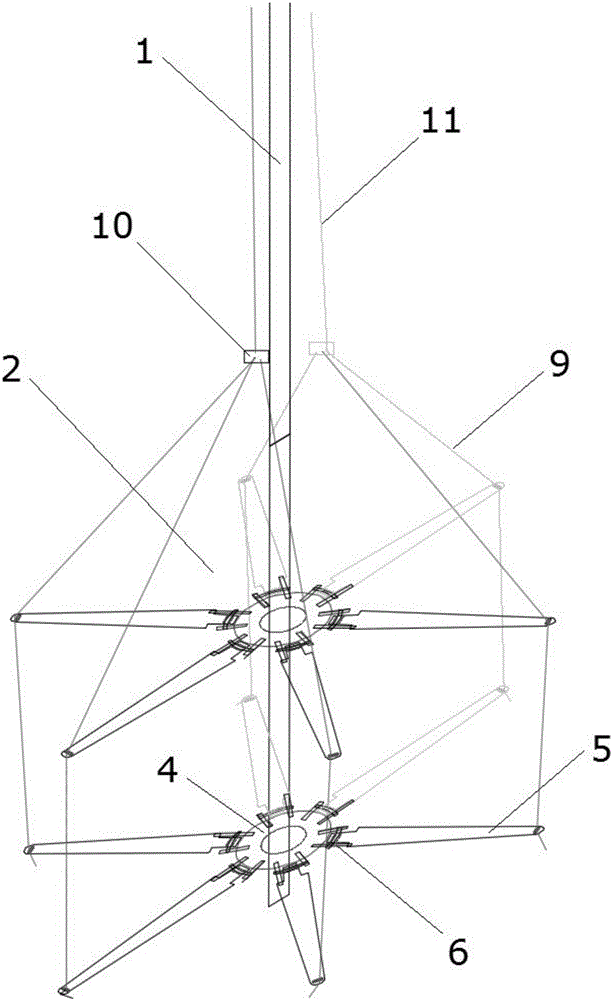

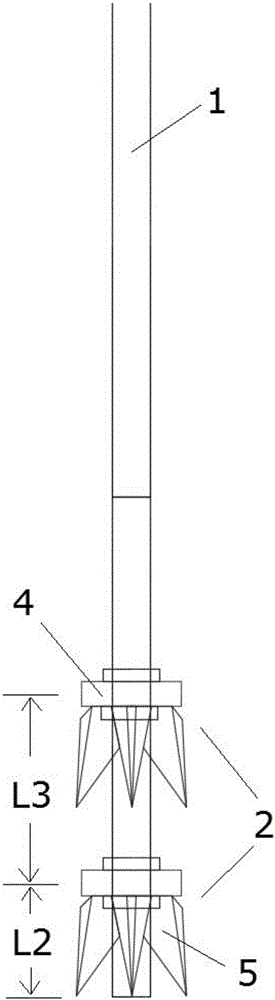

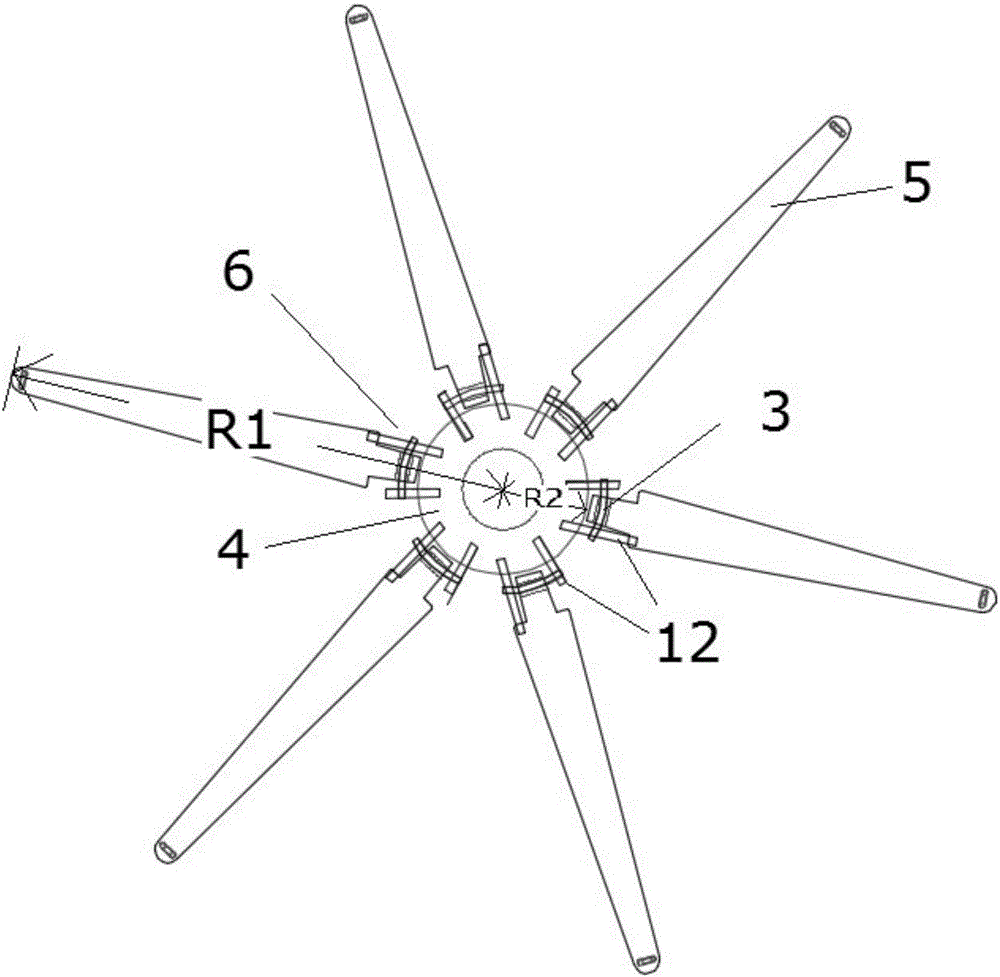

[0022] like figure 1 and figure 2 A valve-type expansion head bolt bearing body is shown, including a bolt 1, a fixed card 10, a first pull rope 9, a second pull rope 11 and two valve-shaped Expand head 2. The valve-type expanding head 2 includes a circular steel pipe reinforcement 4 and six valve arc-shaped steel plates 5, the circular steel pipe reinforcement 4 is sheathed on the anchor rod 1, and the inner ends of the six valve arc-shaped steel plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com