Push-type fast anchoring and installation of bonded hollow anchor rods

A bolt and hollow technology, which is used in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of complex and changeable geological conditions, high cost of resin bolts, difficulty in forming anchor holes, etc., and achieve control support engineering cost, improve the quality of anchor bolt construction, and optimize the effect of construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The patent / invention of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

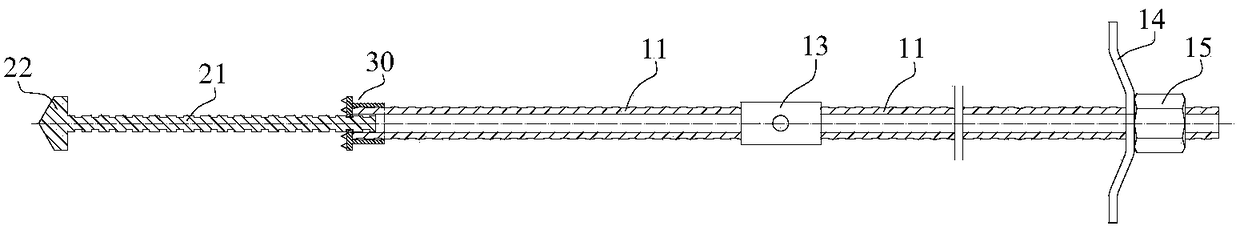

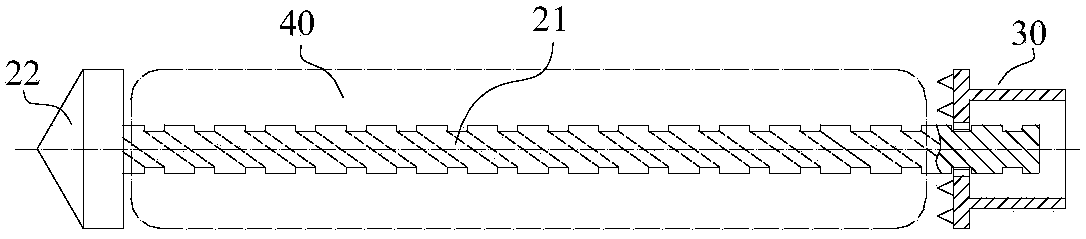

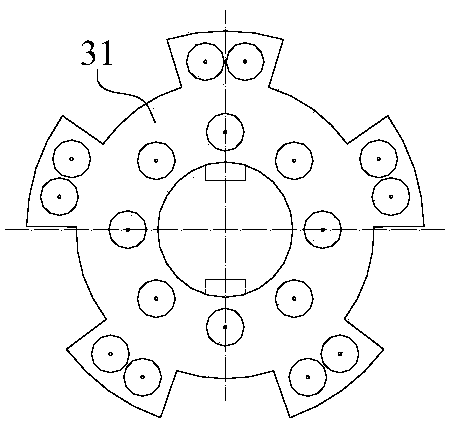

[0019] refer to figure 1 with figure 2 According to the present invention, the push-type fast anchoring bonded hollow anchor rod includes a hollow anchor rod body and an anchor head connected to the rear end thereof consisting of a backing plate 14 and a nut 15 . A pushing screw 21 and a converter 30 assembly are installed on the front end of the hollow anchor rod body, and the bagged anchoring agent 40 is installed on the pushing screw 21 . The pushing screw 21 has a non-self-locking external thread, and cooperates with the converter 30 to form a screw nut mechanism. The front end of the converter 30 is a chainring 31 with several bevel teeth. The front end of the pushing screw 21 has a conical head 22 , and the bagged anchoring agent 40 is installed between the bottom surface of the conical head 22 and the front end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com