Combustion furnace

A combustion furnace and inner casing technology, applied in the field of combustion furnaces, can solve the problems of burning for a long time, poor heat convection effect, uneven combustion in the furnace, etc., achieve better combustion effect, suppress upward burning, The effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

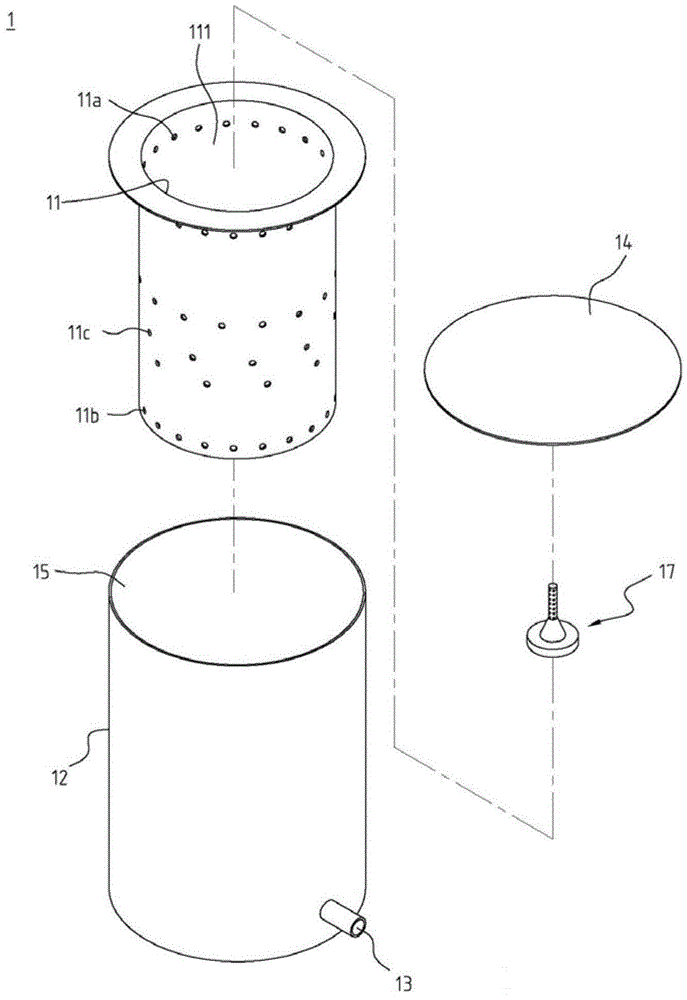

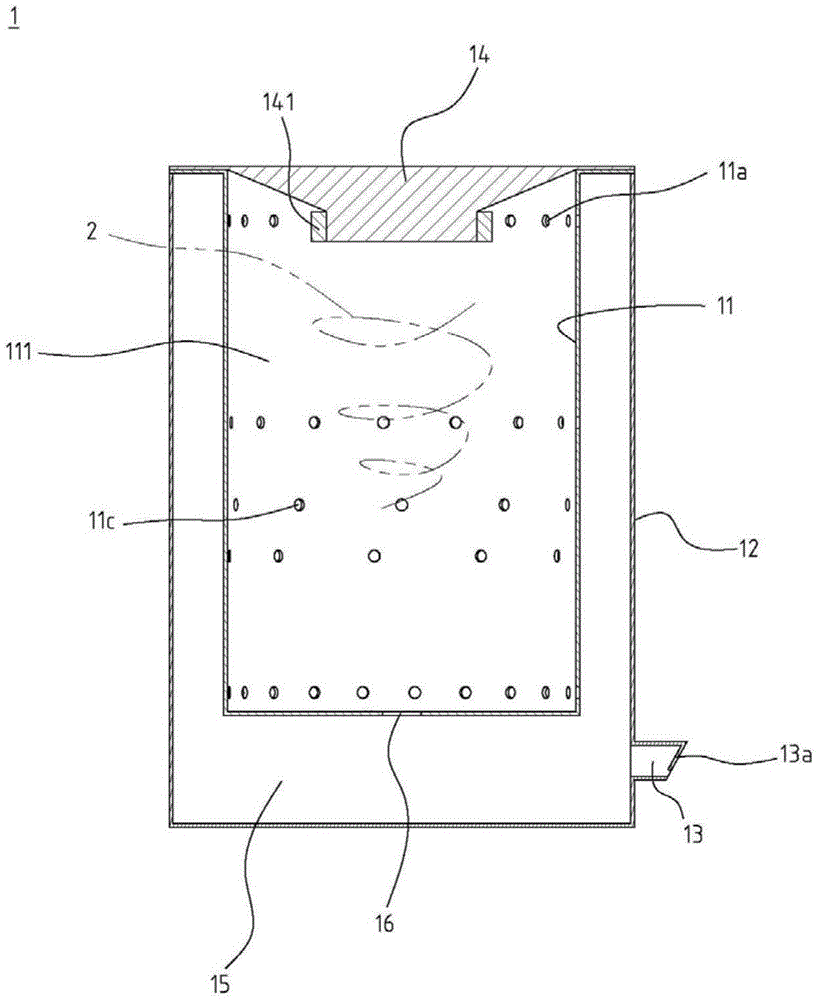

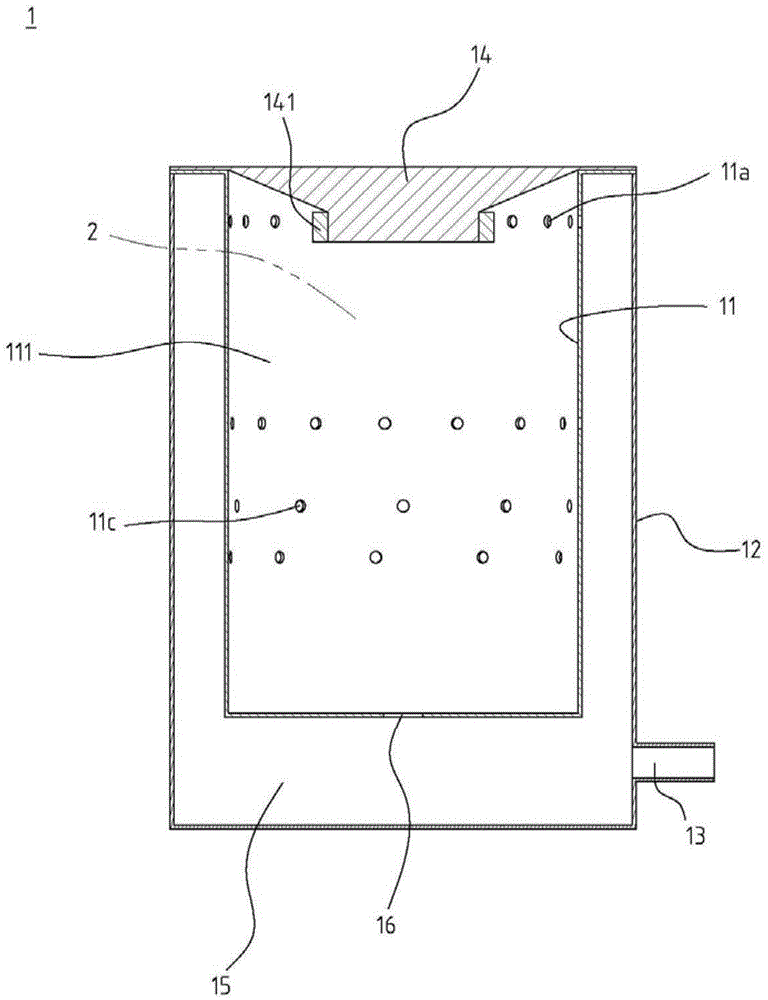

[0061] see figure 1 , respectively are the exploded schematic diagrams of the first embodiment of the combustion furnace of the present invention. The combustion furnace 1 includes an inner casing 11 , an outer casing 12 , an air intake passage 13 and a flame suppression cover 14 . The inner casing 11 forms an accommodating space 111, the upper edge of the inner casing 11 is provided with a plurality of first air holes 11a, the plurality of first air holes 11a surround the upper edge of the inner casing, and the bottom of the inner casing is provided with an inlet Stoma16. The outer casing 12 covers the inner casing 11, and a gas flow space 15 is formed between the inner casing 11 and the outer casing 12, wherein the diameter of the inner casing 11 can range from 40 cm to 70 cm, and the depth and length of the inner casing 11 The range is 60 cm to 130 cm. The pipe diameter of the outer casing 12 can range from 42 cm to 75 cm. The air intake channel 13 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com