Riverbed bed load vertical section separating model test device and use method thereof

A model test device and vertical section technology, applied in the field of basic research on river dynamics and mass movement, to achieve the effect of easy implementation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

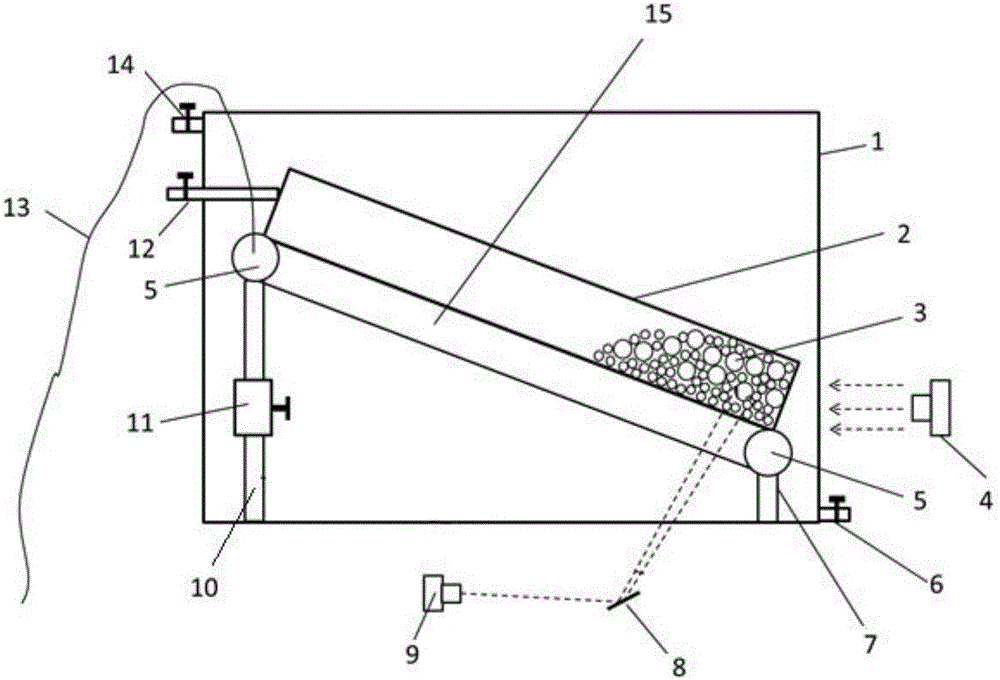

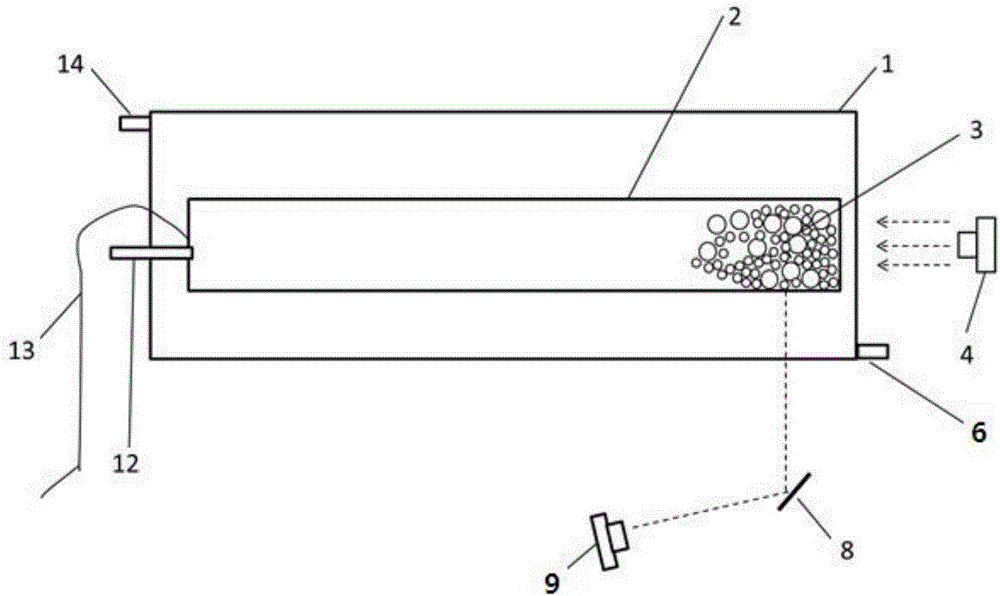

[0031] Example 1: Experimental Research on the Sorting Law of Moving Mass under Different Riverbed Slopes

[0032] Based on the shape and size of the built-in water tank 2 and the conveyor belt 15, combined with the actual scale of the moving mass, two kinds of transparent glass balls 3 particle size specifications are selected, the diameters of the transparent glass balls 3 are 1.5mm and 4mm respectively, and the transparent glass balls are prefabricated 3. The external water tank 1 is prefabricated, and the external water tank 1 is a cuboid whose material is transparent toughened glass with a lower seal and an upper opening, with a width of 35 cm, a length of 150 cm, a height of 80 cm, and a wall thickness of 1.5 cm. Prefabricated built-in water tank 2, its material is transparent toughened glass, and its width is 15cm, and length is 100cm, and height is 30cm, and wall thickness is the cuboid of the top opening of 1cm. The long support 10 and the short support 7 of the pref...

Embodiment 2

[0036] Example 2: Experimental research on the time-scale sorting law of river bed mass flow

[0037] Based on the shape and size of the built-in water tank 2 and the conveyor belt 15, combined with the actual scale of the moving mass, two kinds of transparent glass balls 3 particle size specifications are selected, the diameters of the transparent glass balls 3 are 1mm and 5mm respectively, and the transparent glass balls 3 are prefabricated . Prefabricated external water tank 1, external water tank 1 material is the bottom seal of transparent plexiglass or transparent tempered glass (this embodiment is transparent tempered glass), the cuboid of top opening, width is 45cm, length is 200cm, height is 100cm, wall The thickness is 2cm. The prefabricated built-in tank 2 is made of transparent toughened glass, a cuboid with a width of 25cm, a length of 150cm, a height of 35cm, and a wall thickness of 1cm. The prefabricated aluminum cylindrical conveyor belt has a long support 10...

Embodiment 3

[0039] Example 3: Model test research on mass separation in mountain torrents

[0040] Based on the shape and size of the built-in water tank 2 and the conveyor belt 15, combined with the actual scale of the moving mass, two kinds of transparent glass balls 3 particle size specifications are selected, the diameters of the transparent glass balls 3 are 1.5mm and 4mm respectively, and the transparent glass balls are prefabricated 3. The external water tank 1 is prefabricated, and the external water tank 1 is a cuboid whose material is transparent toughened glass with a lower seal and an upper opening, with a width of 35 cm, a length of 150 cm, a height of 80 cm, and a wall thickness of 1.5 cm. The prefabricated built-in water tank 2 is made of transparent toughened glass, a cuboid with a width of 15cm, a length of 100cm, a height of 30cm, and a wall thickness of 1cm. The prefabricated aluminum cylindrical conveyor belt long support 10 and short support 7 have a cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com