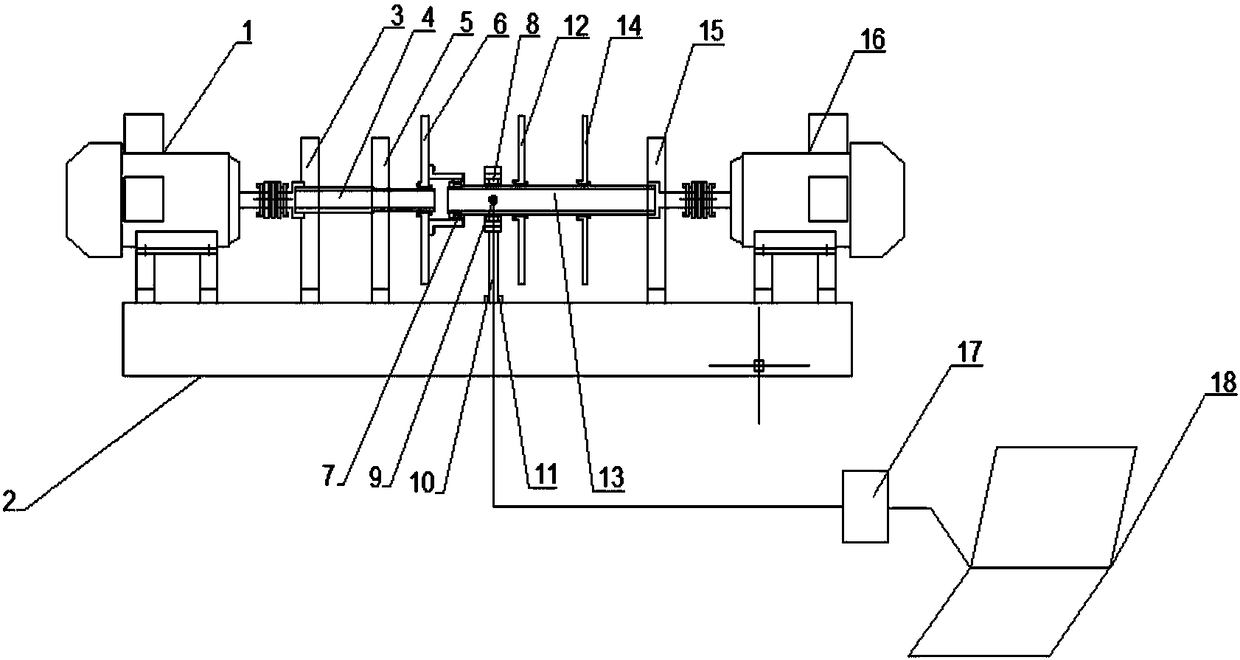

Loading method of aero-engine intermediate bearing double-rotor test bench

A technology of aero-engine and test bench, which is applied in the direction of mechanical bearing testing, etc. It can solve the problems of unfavorable installation of test devices, difficulties in performance research, and constant adjustment of loads, etc., to achieve safe and reliable variable load experiments, simple loading control, and flexible disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in combination with the accompanying drawings and the technical solutions of the description.

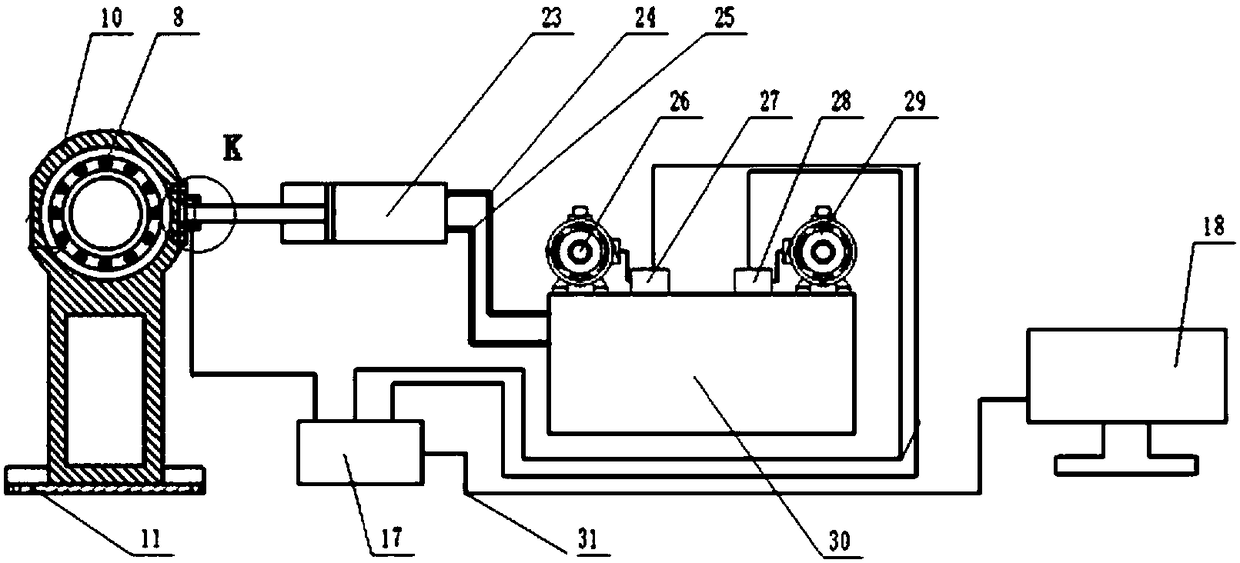

[0015] According to the requirements of the experiment, the load range during the experiment is 200N-5000N, the oil inlet pump 26 and the oil return pump 29 choose the model 5HP-4PCO5-43B0, the oil inlet and oil return pump inverters 27 and 28 choose VF6004M21D, and the pressure sensor 19 is selected according to the load range The model number is VF6004M21D.

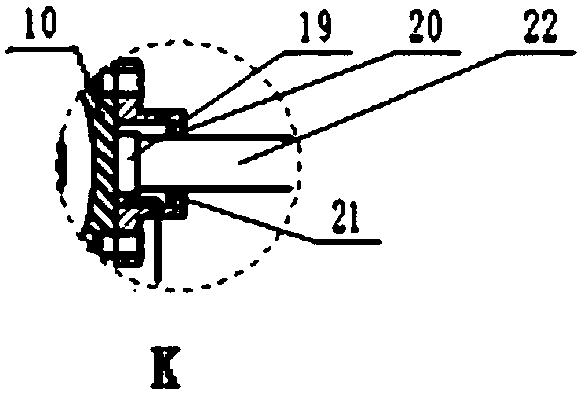

[0016] The experimenter installs the bearing bracket 10 equipped with the bearing 8 for loading on the corresponding position of the test bench through the radial guide groove 11 according to the position where the test bench needs to be loaded, and adjusts the position of the bearing bracket 10 in the radial guide groove 11. To realize the effect of axially fixed and radially guided; the loading bearing 8 is fixed with a bearing end cover. The retaining ring 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com