A mercury interface automatic adjustment system and a core pore structure measuring instrument

An automatic adjustment and pore structure technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low applicability, large measurement error, etc., and achieve the effect of reducing volatilization, reducing mercury volatilization, and preventing mercury volatilization and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

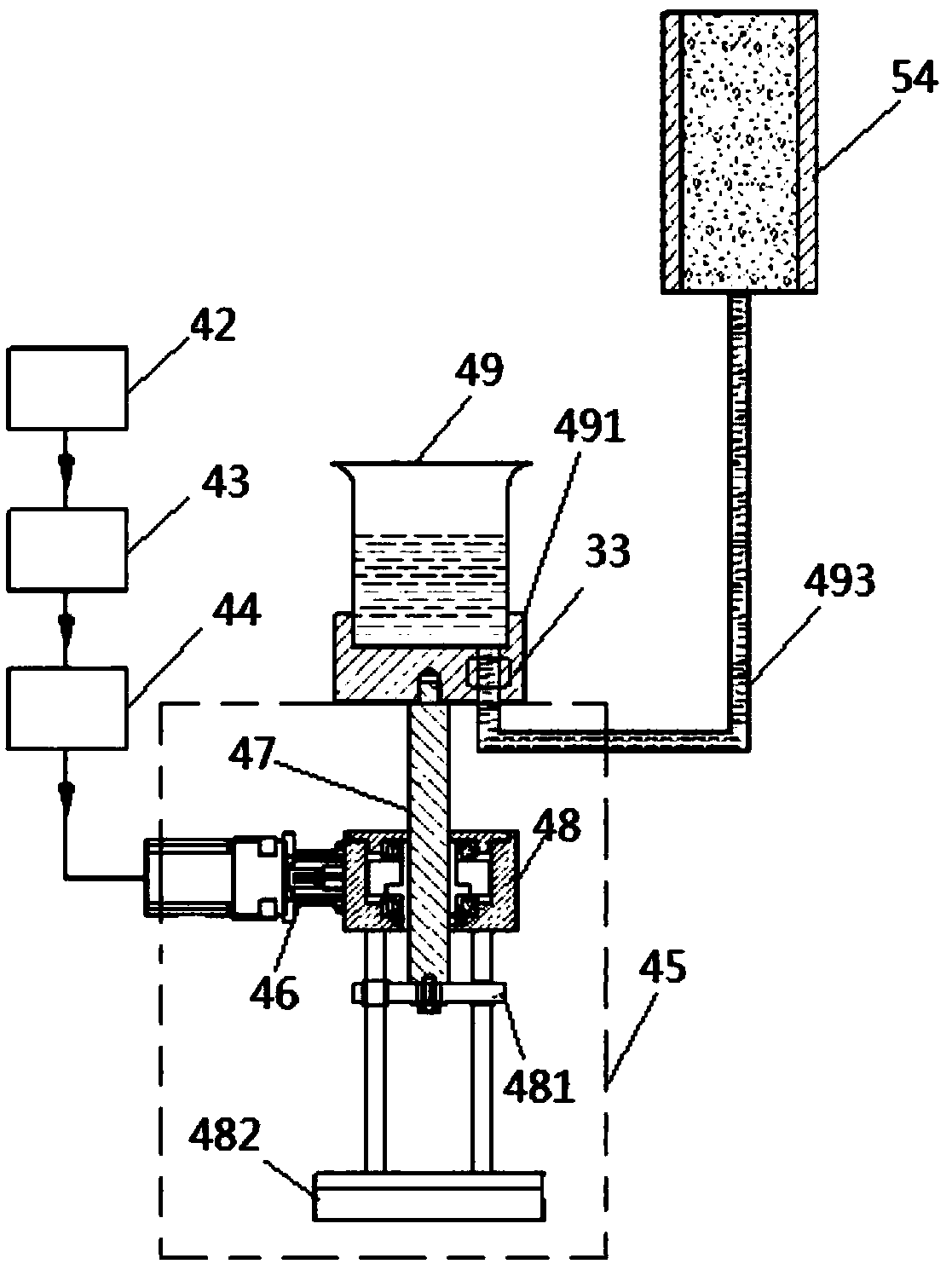

[0025] This specific embodiment discloses a mercury column interface automatic adjustment system, such as figure 1 , including atmospheric pressure gauge 42, acquisition card 43, PLC controller 44, lifting system 45 and mercury cup 49, atmospheric pressure gauge 42, acquisition card 43, PLC controller 44 and lifting system 45 are electrically connected in series in sequence, and mercury cup 49 is located at The upper end of the lifting system 45, the mercury cup 49 is fixedly connected with the lifting system 45 by screws. The mercury cup 49 is connected with a mercury column 54 through a flexible pipe, and the mercury column 54 can also be connected with a core holder to become a simple porosimeter. Wherein, preferably, the atmospheric pressure gauge 42 adopts a digital display atmospheric pressure gauge, which can clearly read the atmospheric pressure value, and is convenient for the operator to obtain the atmospheric pressure situation.

[0026] Specifically, such as figu...

Embodiment 2

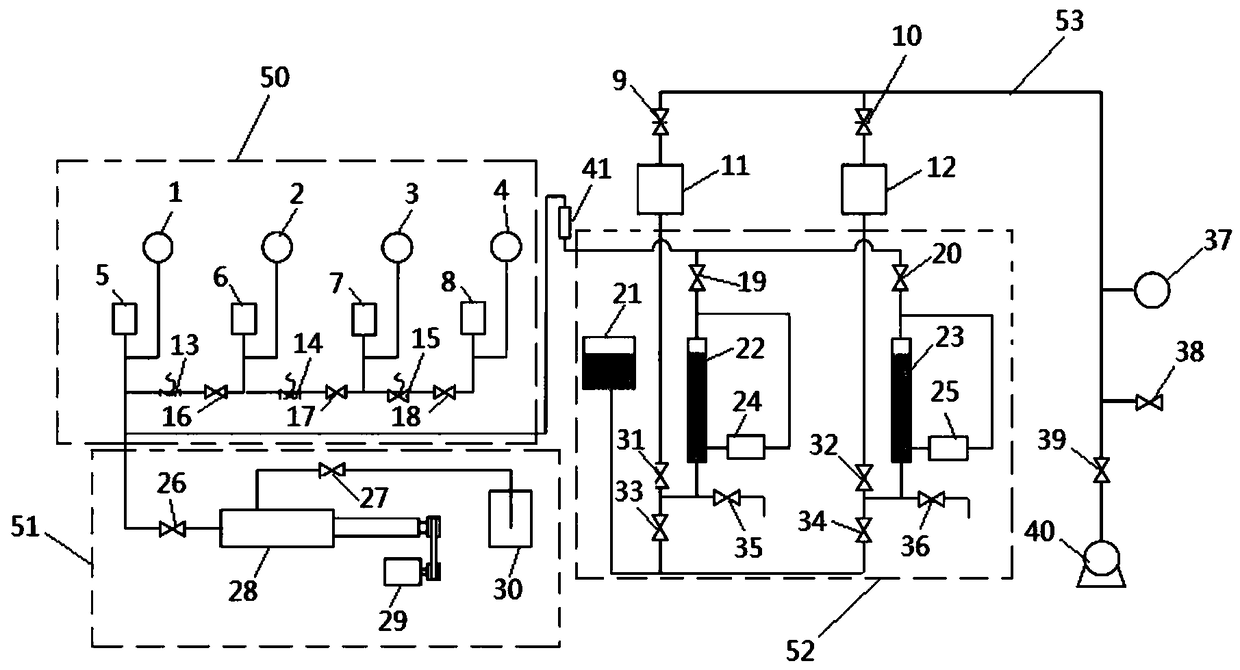

[0031] This specific embodiment discloses a rock core pore structure tester, such as figure 2 , comprising an air pressure detection device 50, an inlet pressure device 51, a pressure metering device 52 and a rock core placement device 53, the air pressure detection device 50 and the inlet pressure device 51 are connected with the pressure metering device 52 through a pipeline, and the rock core placement device 53 is connected with the pressure metering device through a pipeline 52 connections. Preferably, the gas trap 41 is arranged on the connecting pipe of the air pressure detection device 50, the pressure inlet device 51 and the pressure metering device 52.

[0032] Such as figure 2As shown, the air pressure detection device 50 includes a pressure sensor c7 and a pressure sensor 8, the pressure sensor c7 and the pressure sensor 8 are respectively connected with a pressure gauge c3 and a pressure gauge d4, the pressure sensor c7 and the pressure sensor 8 are arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com