Color vision correcting lens, color vision correcting equipment and manufacturing method of color vision correcting lens

A lens and color vision technology, applied in the fields of life medicine and display, to achieve the effect of stable performance, improving perception ability, and promoting social progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings.

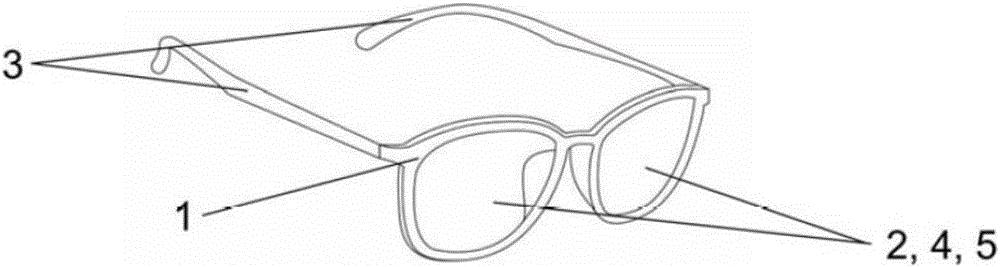

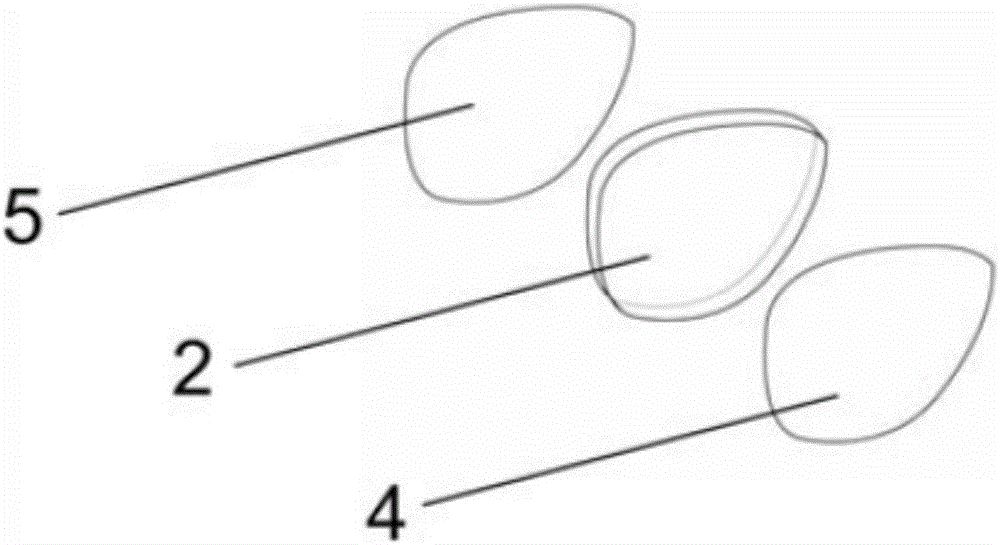

[0048] Such as Figure 1(a) ~ Figure 1(c) As shown, a kind of color vision correction glasses is composed of a frame 1, two lenses 2 fixed on the frame 1, two temples 3, a multilayer film stack 4 and a multilayer film stack 5, wherein the multilayer film stack 4 is deposited on the front of the two lenses 2 (we define the side away from the eyes as the front), and the multilayer film stack 5 is deposited on the back of the two lenses 2, and the two lenses can be plano lenses, myopia lenses or hyperopia lenses.

[0049] In the color vision correcting glasses of the present invention, the optical characteristics realized by the special film system on the two lenses are obviously different from those of general lenses without the film system. Ordinary ordinary lenses often need to achieve high transmission (above 92%) in the range of 380nm-780nm in the visible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com