Light filter, camera module and manufacturing method thereof

A camera module and optical filter technology, which is applied in the fields of optical filter, optics, image communication, etc., can solve the problems of stray light of camera module, affecting the image quality of mobile phone camera module, stray light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

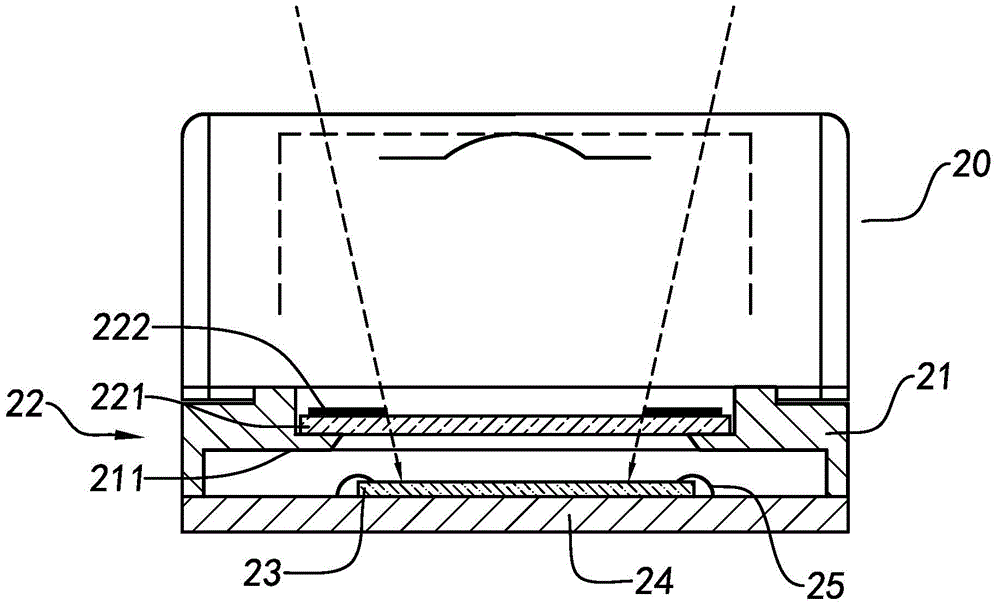

[0048] The light blocking film 222 is coated on the surface of the infrared cut filter 221 by a photolithography method, which is a traditional yellow light process.

[0049] The photoresist used in the yellow light process is a photosensitive material. The photoresist has unique characteristics. Under the action of UV light, it will undergo chemical changes and become a substance that is easily soluble in acid or alkali. Apply the photoresist on the substrate, provide the corresponding photomask according to the shape required by the product, cover the photomask on the photoresist, and then expose the photoresist so that there is no photoresist covered by the photomask A chemical change occurs in the area, and then this part of the photoresist is dissolved or retained with acid or alkali to form a pattern that is the same or complementary to the shape of the mask.

[0050] The photoresist used in the present invention is an opaque coating, which not only has the photosensitiv...

Embodiment 2

[0055] The light blocking film 222 is coated on the infrared cut filter 221 through a silk screen printing process. The ink used in the silk screen printing is an opaque material, and the ink is applied to the light blocking area of the infrared cut filter 221 through a silk screen printing process, thereby forming the light blocking film 222 . The silk screen printing process can be printed by the basic principle that the mesh in the blackened position of the screen printing plate is ink-permeable, and the mesh in the light-transmitting area is impermeable to ink.

[0056] The shape of the ink-permeable part of the screen printing plate should be consistent with the shape of the light-shielding film 222, which is a ring shape. Other parts of the screen printing plate are impermeable to ink. When making, first align the screen printing plate with the infrared cut-off filter 221, pour the ink on the screen printing plate, and apply a certain amount of ink to the ink with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com