A horizontal pressing equipment for rapid prototyping of wind power tower door frame

A technology for wind power towers and door frames, applied to metal processing equipment, etc., to achieve the effects of improving processing progress and work efficiency, convenient operation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

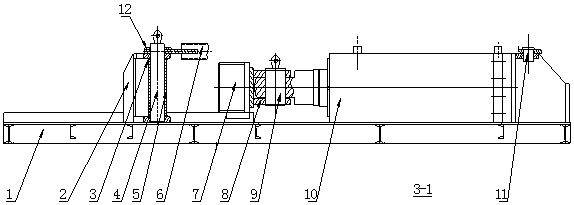

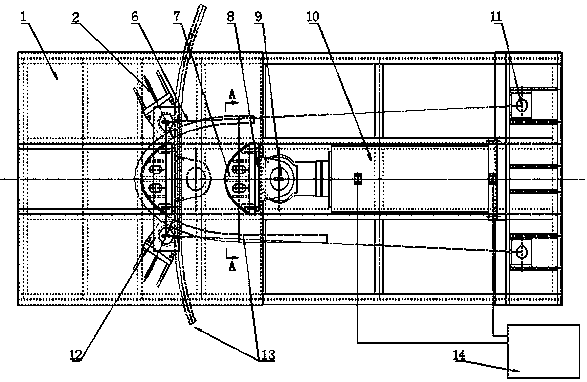

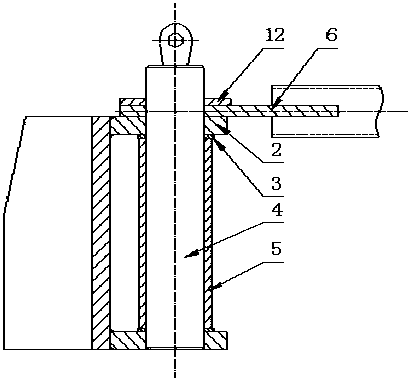

[0025] like figure 1 , 2 As shown, the horizontal pressing equipment of the wind tower door frame press molding of the present invention comprises mold base 1, die base 2, die shaft 4 and die shaft sleeve 5, punch 7, punch hinge seat 8, hinge shaft 9 , transverse pull rod 12, longitudinal pull rod 6, pull rod shaft 11; the die base 2 is welded on the die base 1, and the retaining ring 3 is assembled on the die base 2, and the die shaft 4 is assembled on the die base 2 , the die shaft sleeve 5 is set on the die shaft 4, the punch 7 and the punch hinge seat 8 are connected as a whole by bolts, the punch hinge seat 8 and the hydraulic cylinder 10 are connected by the hinge shaft 9, and one end of the longitudinal tie rod 6 passes through The tie rod shaft 11 is connected to the mold base 1, the other end is connected to the die shaft 4, the transverse tie rod 12 is connected to the upper part of the two die shafts 4, the hydraulic cylinder 10 is connected to the mold base 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com