Method for preparing large-scale high-power carbon electrodes using semi-graphitized anthracite

A semi-graphitization and anthracite technology, applied in the preparation/purification of carbon, etc., can solve the problems that the technical performance indicators cannot meet the use requirements, the production process is difficult to control, and the production process is complicated, so as to improve the main performance indicators and the qualified rate of finished products , Reduce the types of raw materials for production, and the effect of uniform internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

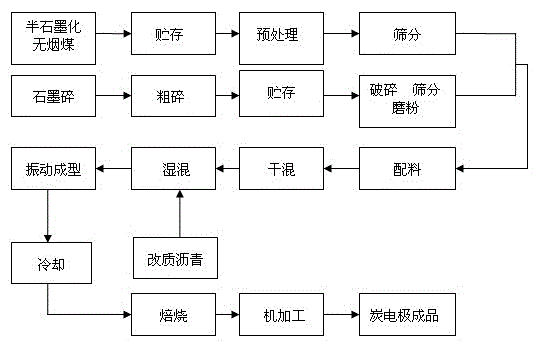

[0031] A method for preparing a large-scale high-power carbon electrode by using semi-graphitized anthracite, the specific process steps are as follows:

[0032] (1) Crushing, sieving, and pulverizing: use Taixi low-ash anthracite as raw material, adopt high-temperature calcination process, and apply high-temperature thermal melting and ash reduction technology to prepare semi-graphitized anthracite. The quality index is: the resistivity reaches 500±50μΩm , the fixed carbon component is greater than 98%, the ash content is less than 2%, the sulfur content is less than 0.02%, the true density is greater than 1.85g / cm3, and the degree of graphitization is 50-70%. The semi-graphitized anthracite is pretreated, crushed, and sieved by a vibrating sieve to be divided into three grades of particle size: 0-4mm, 4-10mm, and 10-16mm. Graphite is broken and ground into powder below 200 mesh, the passing rate of 200 mesh sieve is >100%, and the purity is controlled at 70±5%.

[0033] (2)...

Embodiment 2

[0044] A method for preparing a large-scale high-power carbon electrode by using semi-graphitized anthracite, the specific process steps are as follows:

[0045](1) Crushing, sieving, pulverizing: with embodiment 1.

[0046] (2) Ingredients: graphite crushed as powder, semi-graphitized anthracite as aggregate, semi-graphitized anthracite and graphite crushed according to the weight ratio of 33:46 in the electronic automatic batching system for batching; semi-graphitized anthracite 0~ The 4mm particle size material is 18 parts by weight, the 4-10mm particle size material is 5 parts by weight, and the 10-16mm particle size material is 10 parts by weight, and the batching error is less than 5‰.

[0047] (3) Mixing: Add 23 parts by weight of modified asphalt at a temperature of 170±10° C., and the rest are the same as in Example 1.

[0048] (4) Forming: the paste was vacuumized, pressurized, and vibrated simultaneously for 15 minutes in the mold bucket, and all the other were wit...

Embodiment 3

[0055] A method for preparing a large-scale high-power carbon electrode by using semi-graphitized anthracite, the specific process steps are as follows:

[0056] (1) Crushing, sieving, pulverizing: with embodiment 1.

[0057] (2) Ingredients: graphite crushed as powder, semi-graphitized anthracite as aggregate, semi-graphitized anthracite and graphite crushed according to the weight ratio of 37:42 in the electronic automatic batching system; semi-graphitized anthracite 0~ The 4mm particle size material is 21 parts by weight, the 4-10mm particle size material is 6.5 parts by weight, and the 10-16mm particle size material is 9.5 parts by weight, and the batching error is less than 5‰.

[0058] (3) Mixing: Add 21 parts by weight of modified asphalt at a temperature of 170±10° C., and the rest are the same as in Example 1.

[0059] (4) Forming: the paste was vacuumized, pressurized, and vibrated simultaneously for 12 minutes in the mold bucket, and all the other were with embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| degree of graphitization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com