Six-axis industrial robot speed measuring method based on FPGA

An industrial robot, six-axis technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of speed measurement error, consumption of large LE resources, inconvenient speed measurement, etc., to improve measurement accuracy and save logic resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

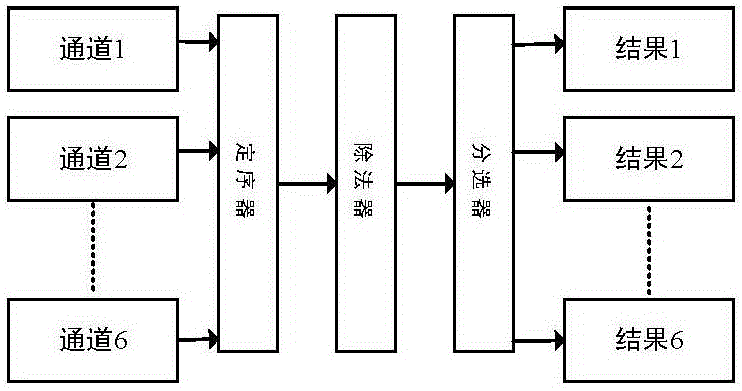

[0015] An FPGA-based method for measuring the speed of a six-axis industrial robot includes two parts: the realization step of the motor speed measurement method and the realization step of a multi-channel divider. The motor speed measurement implementation steps include:

[0016] Step 1: Motor Speed Measurement

[0017] ①If there are M pulses in the 50us timer, M≥2, and the time from the rising edge of the first pulse to the rising edge of the M pulse is T, then the speed=M*pulse equivalent / T; ②If If the number of pulses M appears in the 50us timer, if M≤1, continue to wait; ③If two pulses appear outside the 50us timer, and the time between the two pulses is T, then the speed = pulse equivalent / T ; ④ If a pulse or zero pulse appears outside the 50us timer, the speed at this time is considered to be 0; ① and ③ achieved by the motor speed measurement have 1 / T, if each axis uses a divider , need to consume a lot of LE resources, in order to realize multi-axis logic sharing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com