Negative-pressure auxiliary rod cluster-provided self-adaptive robot hand device

A technology of robot hands and auxiliary rods, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of complex structure, poor reliability, high cost of fluid source, etc., and achieve simple device structure, high gripping stability, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

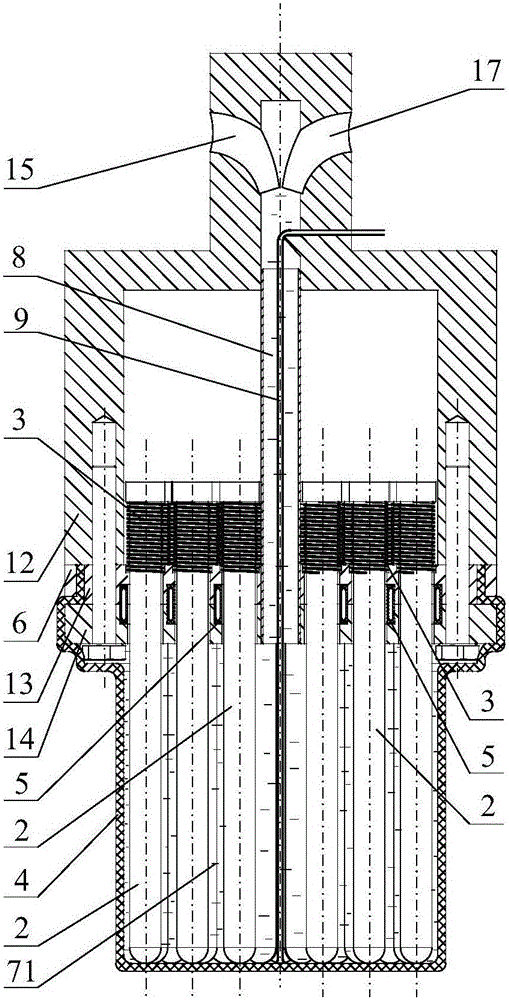

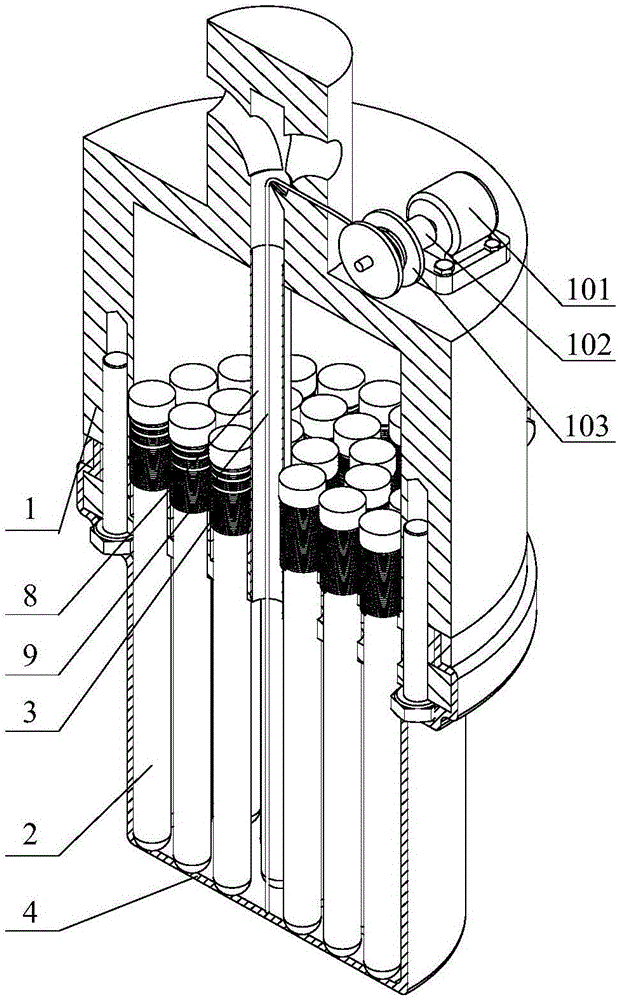

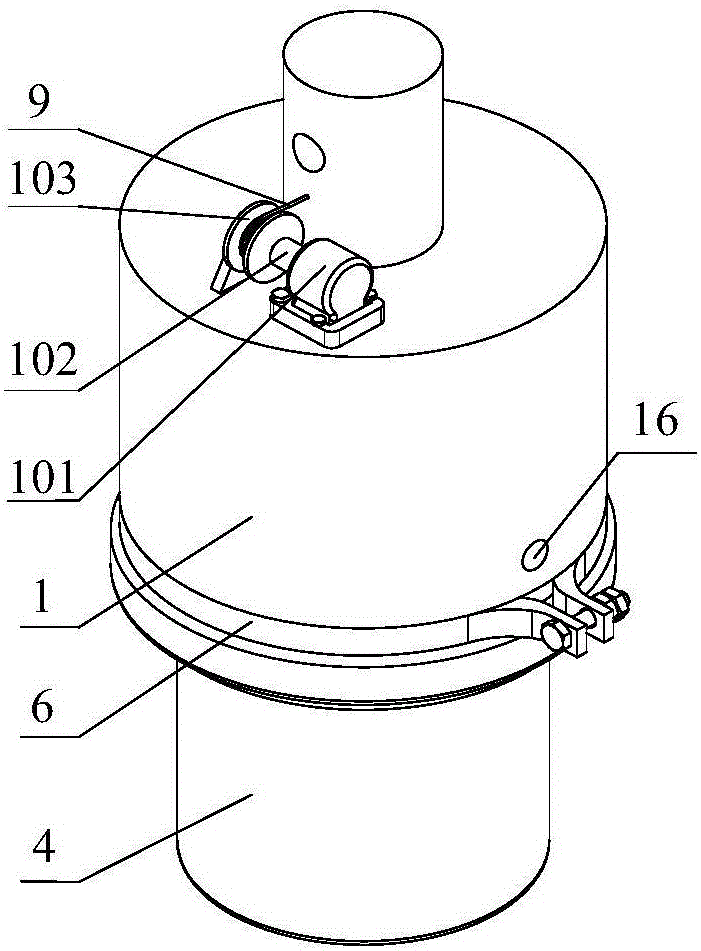

[0057] The specific structure, working principle and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0058] A negative pressure auxiliary rod cluster adaptive robot hand device designed by the present invention includes a base and K sliding push rods; one end of each sliding push rod is slidably embedded in the base and the sliding direction is the same as the sliding push rod The centerlines of the sliding push rods are parallel, and the centerlines of all the sliding push rods are parallel to each other; the fluid flexible rod cluster adaptive robotic hand device provided by the present invention is characterized in that: the negative pressure auxiliary rod cluster adaptive robotic hand device also includes an elastic film , an elastic film tube, a film member, a driver, a transmission mechanism, a first fluid, a second fluid, a first fluid drive source, a second fluid drive so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com