SIM (subscriber identity module) card base cutting machine

A cutting machine and cutting technology, which is applied in metal processing, winding strips, thin material processing, etc., can solve the problems of raw material waste, SIM card accuracy and low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

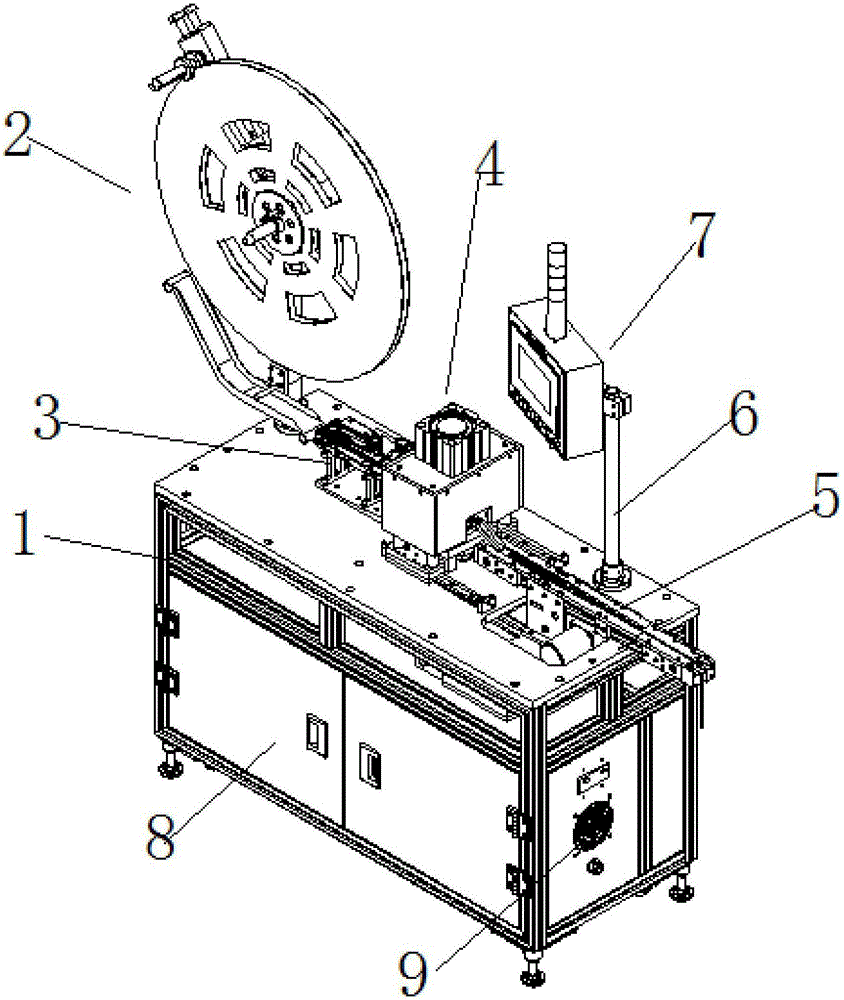

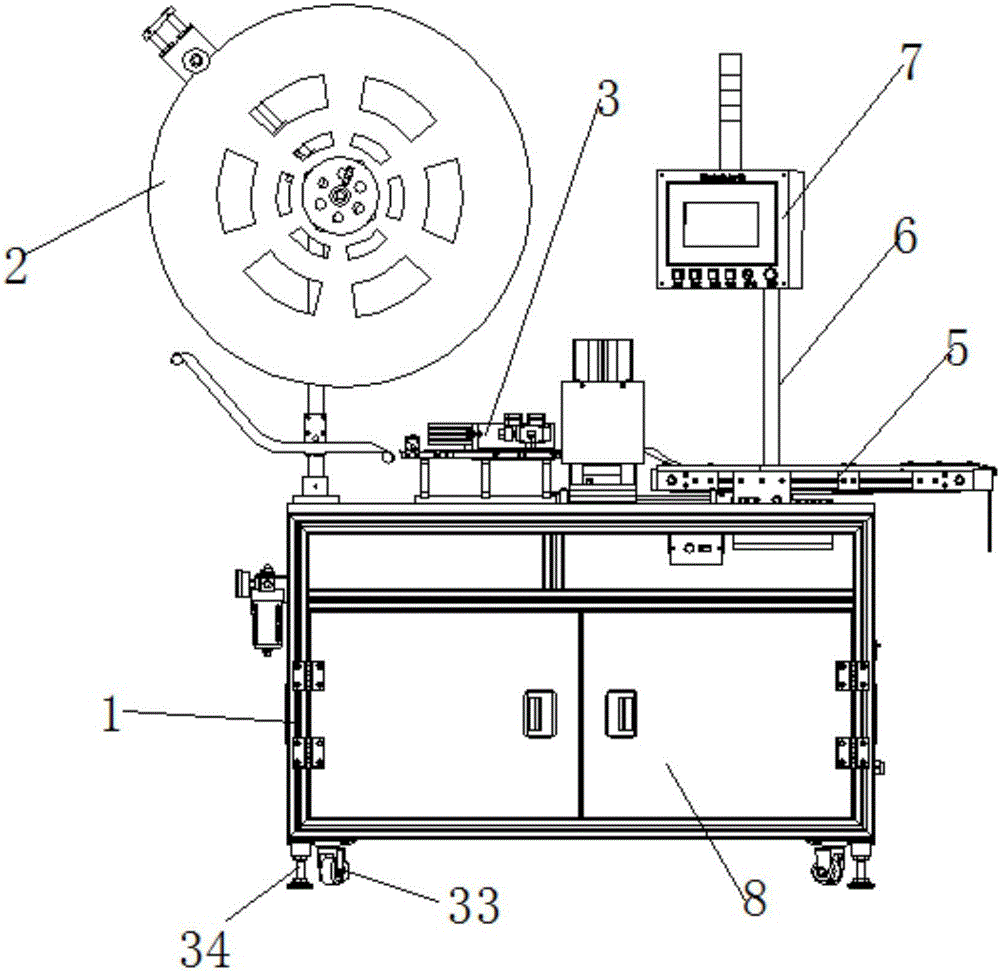

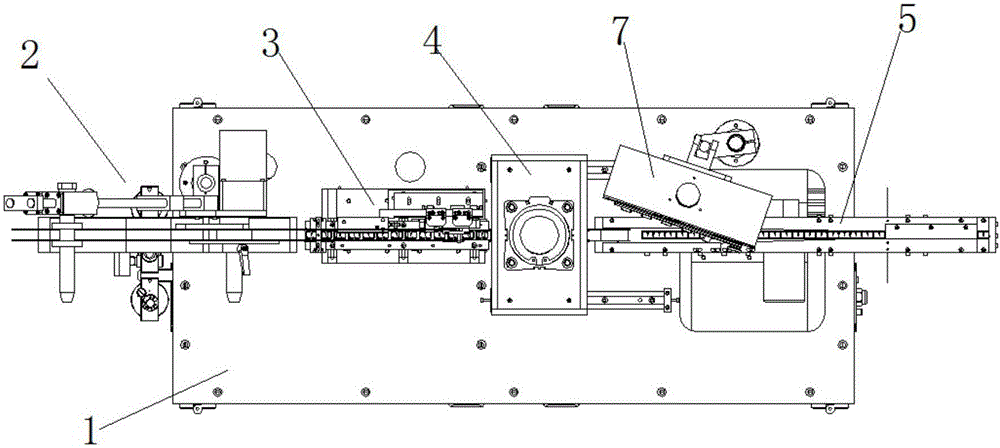

[0025] Such as figure 1 and combine Figure 2 to Figure 9 As shown, a SIM card base cutting machine includes a support frame 1, a material rack 2 is provided on the left side of the upper end surface of the support frame 1, and a feeding mechanism 3 is provided on the right side of the material rack 2. The right side of the mechanism 3 is provided with a cutting die 4, the right side of the cutting die 4 is provided with an assembly line mechanism 5, and the upper right rear part of the support frame 1 is provided with a first pole 6, the The upper end of the first pole 6 is connected with a control device 7, and the feeding mechanism includes a first support plate 10 and a second support plate 13, and the upper end surface of the first support pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap