Composite waterborne floating-body rack system for photovoltaic power generation and manufacturing process of composite waterborne floating-body rack system for photovoltaic power generation

A composite material and photovoltaic power generation technology, applied in the field of floating platforms, can solve problems such as the difficulty in meeting the 25-year life cycle requirements of photovoltaic power plants, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

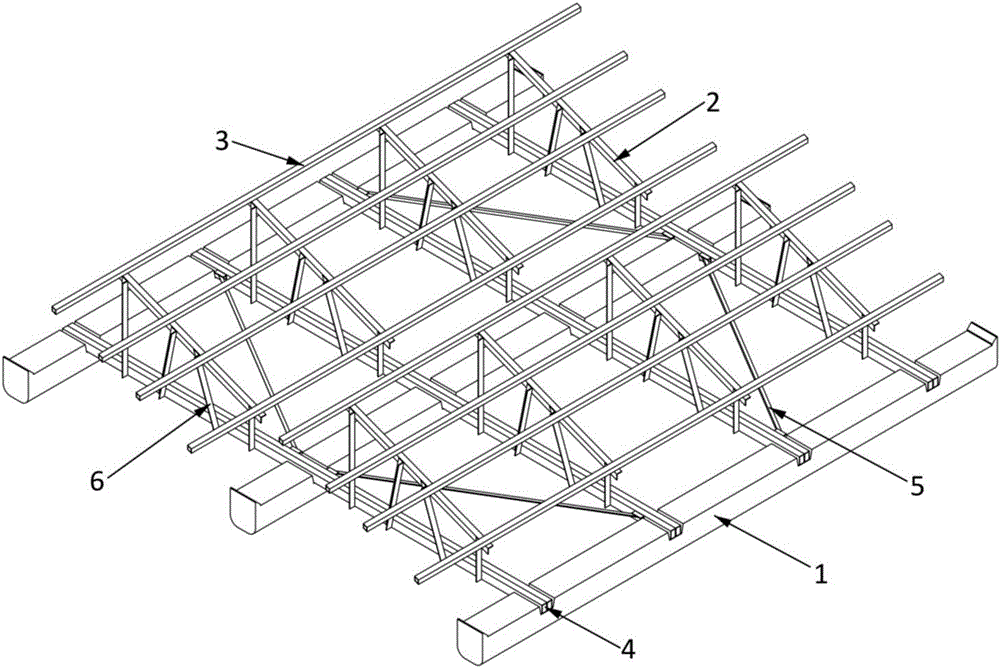

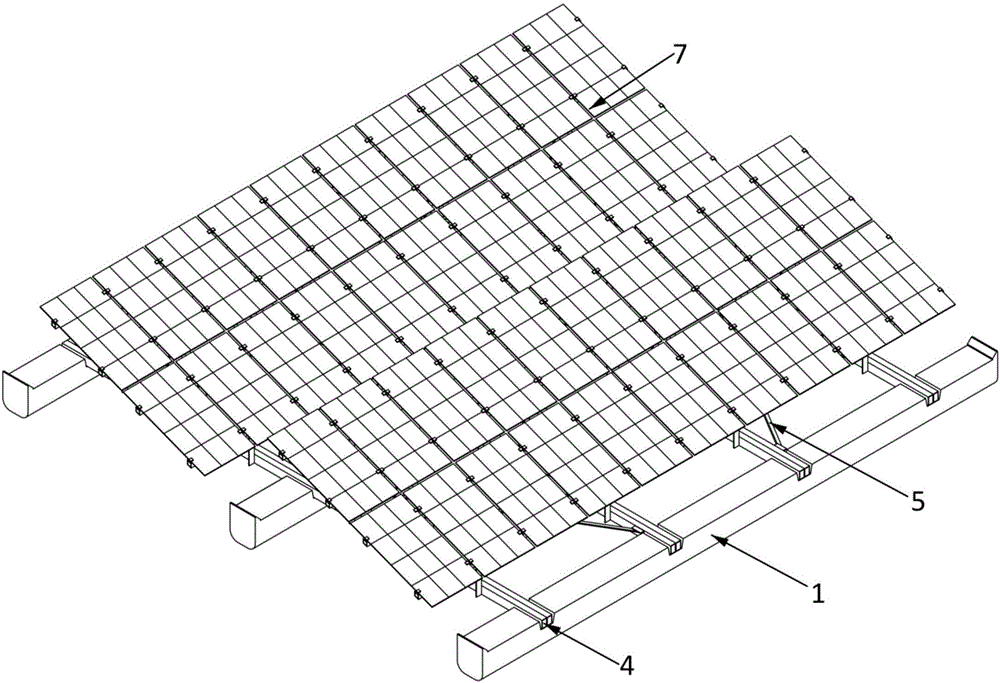

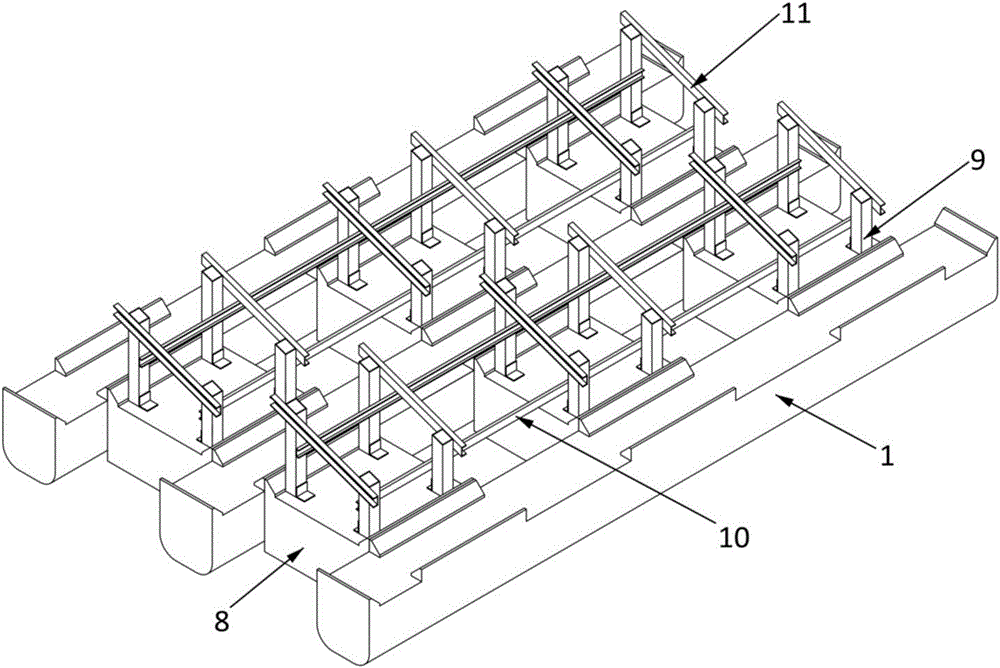

[0038] Such as Figure 1-17 Shown:

[0039] A composite material water floating body platform system for photovoltaic power generation, the floating body platform system includes a composite material floating body unit A1, a composite material glued beam 4 or a composite material floating body unit B8, and a composite material pultrusion profile;

[0040]When the composite material glued beam 4 is used: the upper surface of the composite material floating body unit A1 is provided with grooves at intervals, and the composite material glued beam 4 is placed in the groove, and is connected to the composite material floating body unit A1 through bolts 12 Connecting multiple composite floating body units A1 horizontally into a whole; the composite floating body unit A1 is provided with embedded steel sheets 13, and the embedded steel sheets 13 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap