Control surface suitable for course autostability and control of high-aspect-ratio flying wing arranging airplane

A technology of aircraft heading and large aspect ratio, applied in the field of flying wing layout aircraft heading control, can solve the problems of lift reduction and other problems, achieve the effect of small drag increment, small channel coupling, and meet the requirements of heading control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

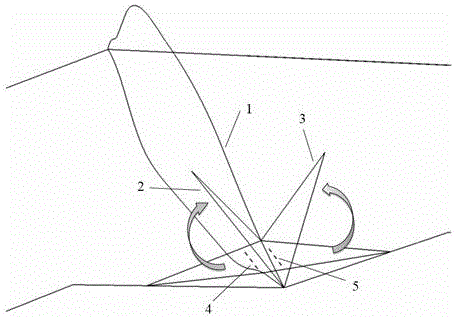

[0022] Such as figure 1 As shown, the control surface of the present invention suitable for course stabilization and control of a large-aspect-ratio flying-wing layout aircraft is located at the rear of the aircraft fuselage 1, and is composed of a left control surface 2 and a right control surface 3, and the left and right sides are controlled The surfaces are symmetrically placed, wherein the left control surface is connected to the fuselage 1 through the left rotation axis 4, and the right control surface is connected to the fuselage 1 through the right rotation axis 5, and the directions of the left rotation axis 4 and the right rotation axis 5 of the control surface are both in the direction of the axis of the fuselage 1 Consistently, the left rotating shaft 4 and the right rotating shaft 5 are fixedly connected to the fuselage 1, and the control steering gear is installed inside the fuselage 1.

[0023] The left control surface 2 and the right control surface 3 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com