Modification method of high-rank coal for slag-tap boiler of entrained flow bed

A liquid slag discharge and high-rank coal technology, applied in the field of coal chemical industry, can solve the problems of high cost, high coal quality requirements, difficult coal blending, etc., and achieve the goals of widening the selection range, reducing raw material and operating costs, and prolonging the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Shanxi Lu'an Yuwu coal was used as the test coal. Shanxi Lu'an Yuwu coal belongs to high-rank coal and is a bituminous coal with a high degree of coalification. It has high carbon content and high calorific value. It is not suitable for entrained bed liquid slag removal furnace.

[0015] Take 93 tons of SiO 2 , 2 tons of Fe 2 o 3 , 0. 6 tons of Al 2 o 3 Mix evenly and pulverize into 200-mesh powder to prepare Modifier A;

[0016] Take 93 tons of CaCO 3 , 2 tons of MgCO 3 , 1 ton of CaO and 0.5 ton of MgO were mixed uniformly and pulverized into a powder of <1 mm to prepare Modifier B;

[0017] Take 10 tons of Lu'an coal, add 350kg of modifier A and 650kg of modifier B to it, and mix well. After testing, the homogenization effect of coal quality is obvious, and the fluctuation range of various indicators is obviously smaller.

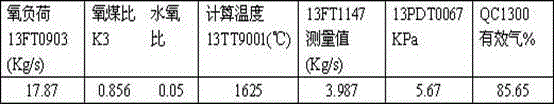

[0018] Industrial trial firing

[0019] The modified Lu'an coal was fired in a Shell furnace for a period of 7 days. The operation of ...

Embodiment 2

[0024] A high-sulfur coal in Linfen, Shanxi was used as the test coal, and the high-sulfur coal was high-rank coal. The coal quality indicators are as follows:

[0025] Mad / % Aad / % Vad / % St,ad ,% Ash melting point M166 0.93 16.32 16.04 3.04 >1500

[0026] Poor viscosity, it is not suitable for entrained bed liquid slagging furnace.

[0027] Take 95 tons of SiO 2 , 2.5 tons of Fe 2 o 3 , 1 ton of Al 2 o 3 Mix evenly and pulverize into 200-mesh powder to prepare Modifier A;

[0028] Take 95 tons of CaCO 3 , 2.5 tons of MgCO 3 , 2 tons of CaO and 1 ton of MgO were mixed uniformly and pulverized into a powder of <1 mm to prepare Modifier B;

[0029] Take 10 tons of high-sulfur coal, add 400Kg of modifier A and 300Kg of modifier B to the coal, and mix well.

[0030] A 30-day industrial trial burning of the mixed coal was carried out in a Shell furnace. The operation of the gasifier is safe and stable, all indicators are controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com