Furnace roller for tunnel type furnace kiln

A technology of tunnel furnace and furnace roll, which is applied in the field of furnace roll, which can solve the problems of high production cost, high maintenance cost and easy damage, and achieve the effect of lower production cost, reduced maintenance cost and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

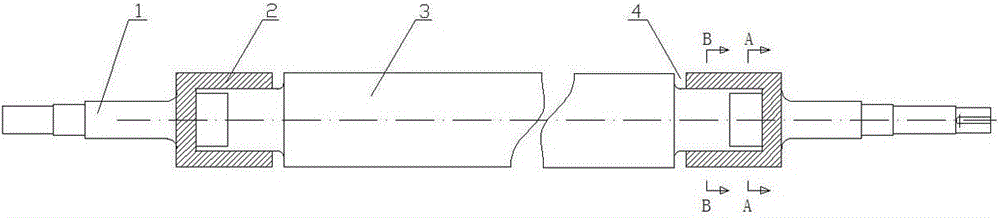

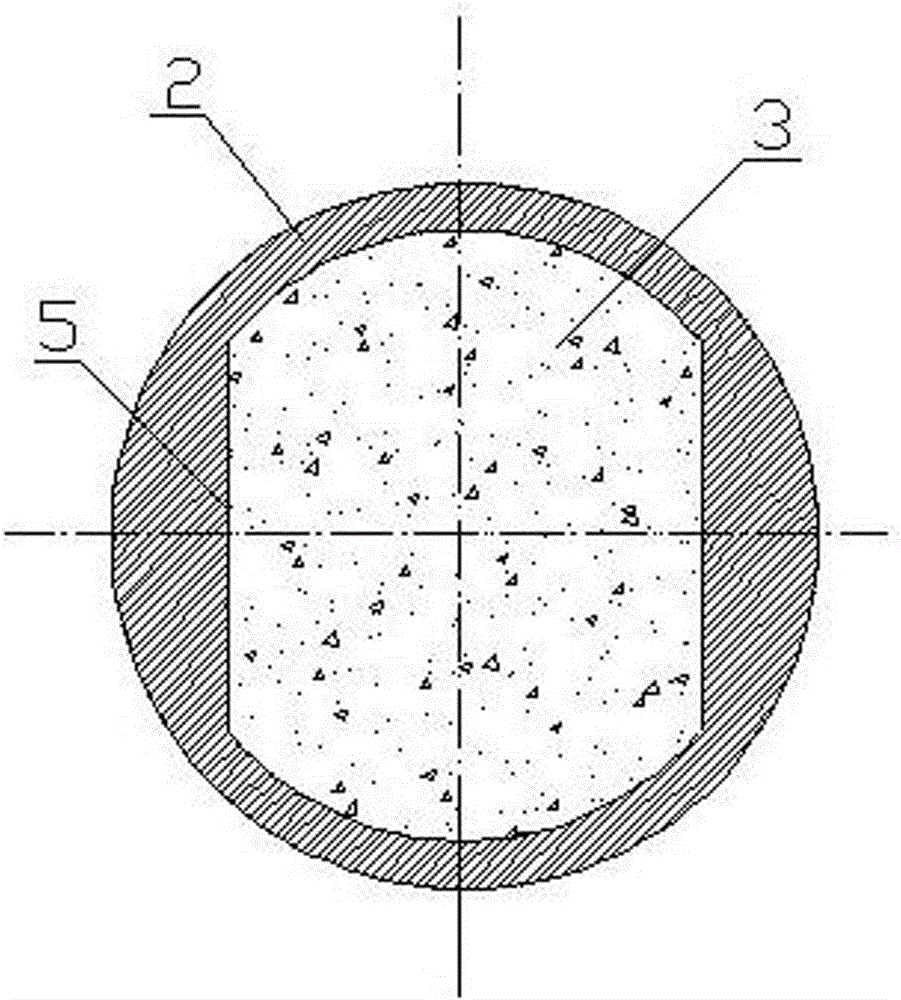

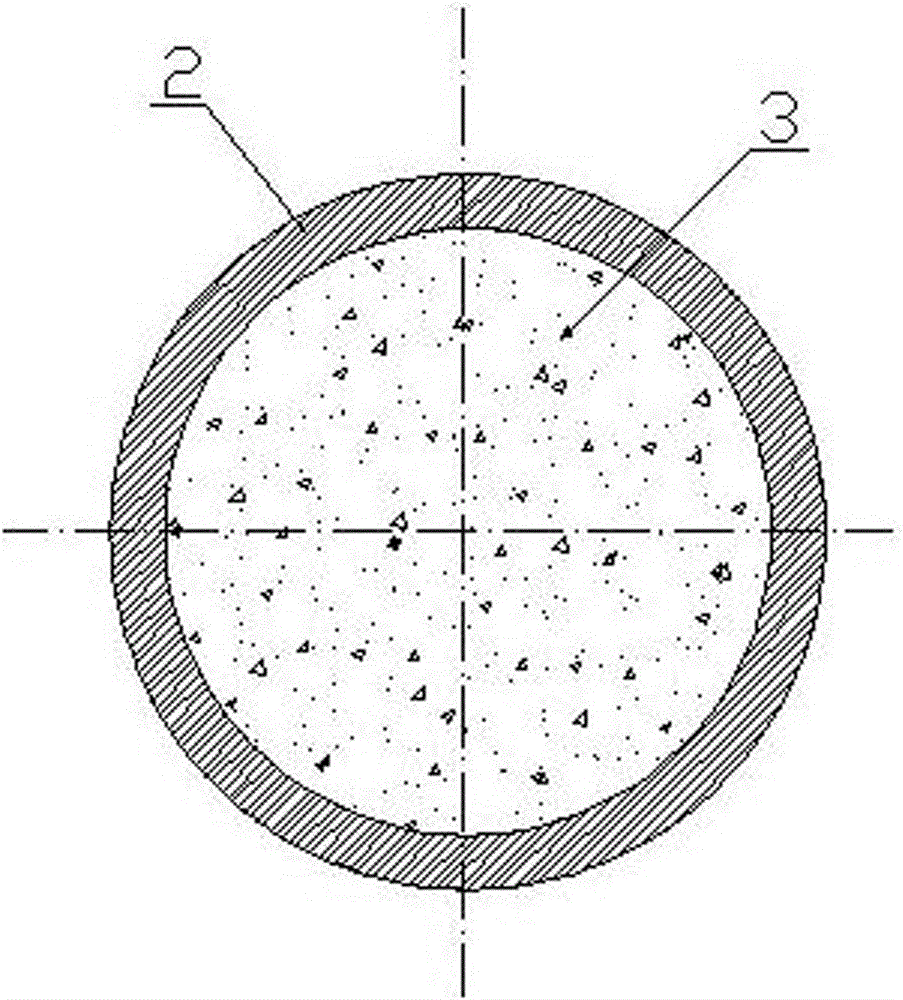

[0012] Such as figure 1 , figure 2 and image 3 As shown, the tunnel furnace roller of the present invention includes a shaft body 3, the shaft body 3 is a solid ceramic roll, the diameter of a section at both ends of the shaft body 3 is smaller than its middle section, and the opposite side of a section at both ends of the shaft body 3 Both planes 5 are processed on the top, and the two planes 5 at the same end are parallel. Both ends of the shaft body 3 are provided with stainless steel shaft heads 1 . The stainless steel shaft head 1 is coaxial with the shaft body 3, and the inner end of the stainless steel shaft head 1 is provided with a shaft sleeve 2, and one end of the shaft sleeve 2 is a closed end, and the closed end and the inner end of the stainless steel shaft head 1 are cast to form an integral structure. The shape of the inner cavity of the shaft sleeve 2 is the same as that of the two ends of the shaft body 3 , and the two ends of the shaft body 3 extend int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com