Heat source tower heat pump unit and simple switching method for refrigerating and heating dual functions of heat source tower heat pump unit

A heat source tower heat pump, dual-function technology, applied in the field of heat pumps, can solve the problems of heat loss, difficult operation, large channel resistance, etc., to improve the evaporation effect and condensation effect, avoid the reduction of energy efficiency, and the effect of small channel resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

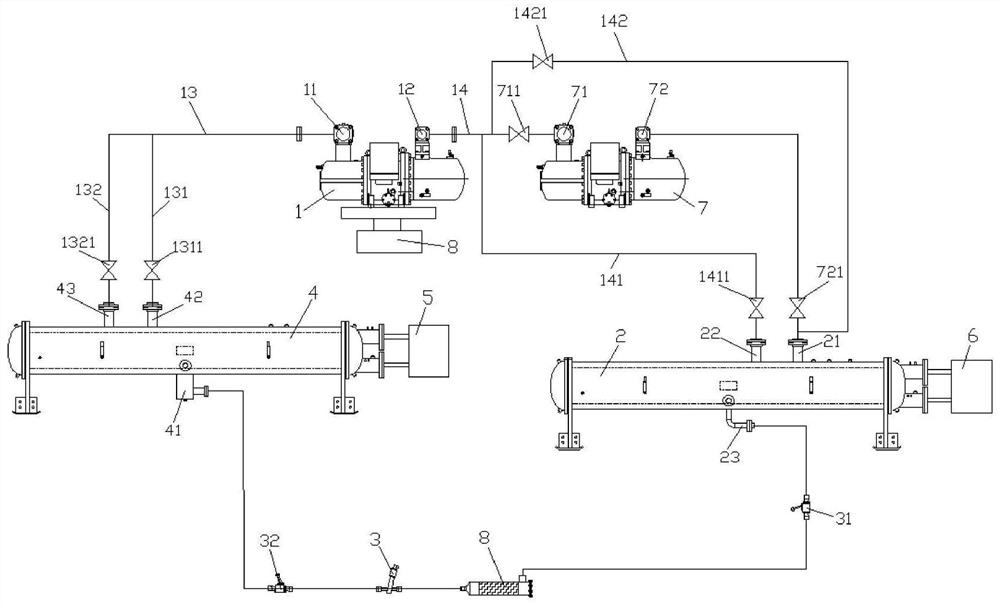

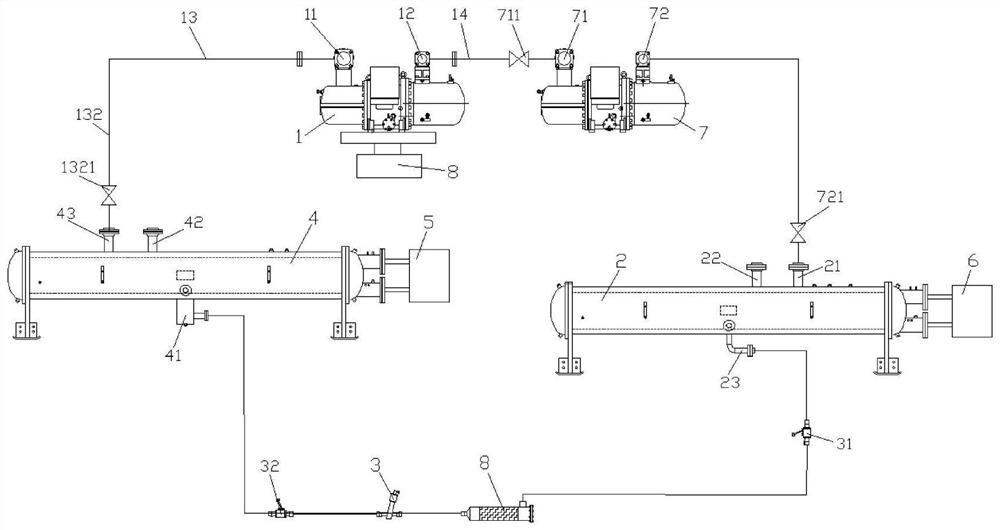

[0025] Such as Figure 7 As shown, a heat source tower heat pump unit includes a first compressor 1, a first heat exchanger 2, a throttling element 3 and a second heat exchanger 4 that are connected and can effectively operate to provide cooling and heating dual functions. A heat exchanger 2 is connected to the indoor unit 6 by water, and the second heat exchanger 4 is connected to the heat source tower 5 by water. The first compressor 1 includes a first suction port 11 and a first exhaust port 12, and the existing heat source The difference between the tower heat pump unit is that the cooling and heating functions of this unit are not switched by changing the two heat exchanger water pipelines, nor by changing the refrigerant flow direction through four-way valves or valves. In the case of a change, only by switching the inlet and outlet of the first compressor 1, the first compressor 1 is rotated and reversed by the reversing device 8 and then reconnected to the pipeline of ...

Embodiment 2

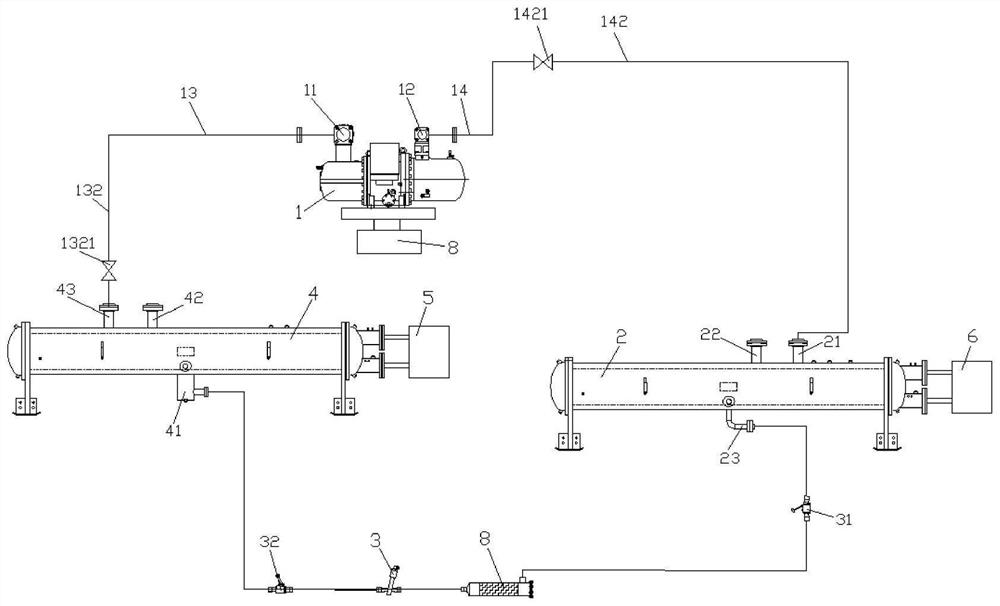

[0027] Such as figure 1 As shown, a heat source tower heat pump unit includes a first compressor 1, a first heat exchanger 2, a throttling element 3 and a second heat exchanger 4 that are connected and can effectively operate to provide cooling and heating dual functions. A heat exchanger 2 is connected to the waterway of the indoor unit 6 for heat exchange with the waterway of the indoor unit 6, and the second heat exchanger 4 is connected to the waterway of the heat source tower 5 for heat exchange with the waterway of the heat source tower 5. A dry filter 8 is provided between the heat exchanger 2 and the throttling element 3, and a first straight-through stop valve 31 is arranged between the dry filter 8 and the first heat exchanger 2, and the throttling element 3 and the second exchanging A second straight-through stop valve 32 is provided between the heaters 4;

[0028] The first compressor 1 is connected to the first heat exchanger 2 through the second connecting pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com