A thermal power measuring device

A technology for measuring device and thermal power, applied in the direction of measuring device, measuring heat, calorimeter, etc., can solve the problems of fluctuation, trouble and large volume of output thermal signal of electric bridge, achieve stable thermal power signal and simplify sample loading Process, chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, thermal power measuring device

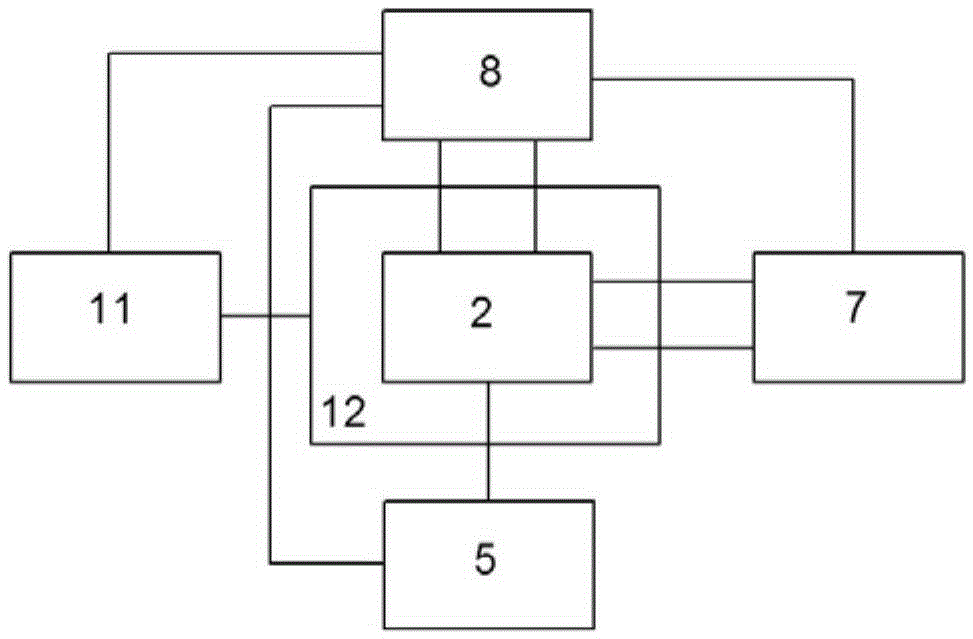

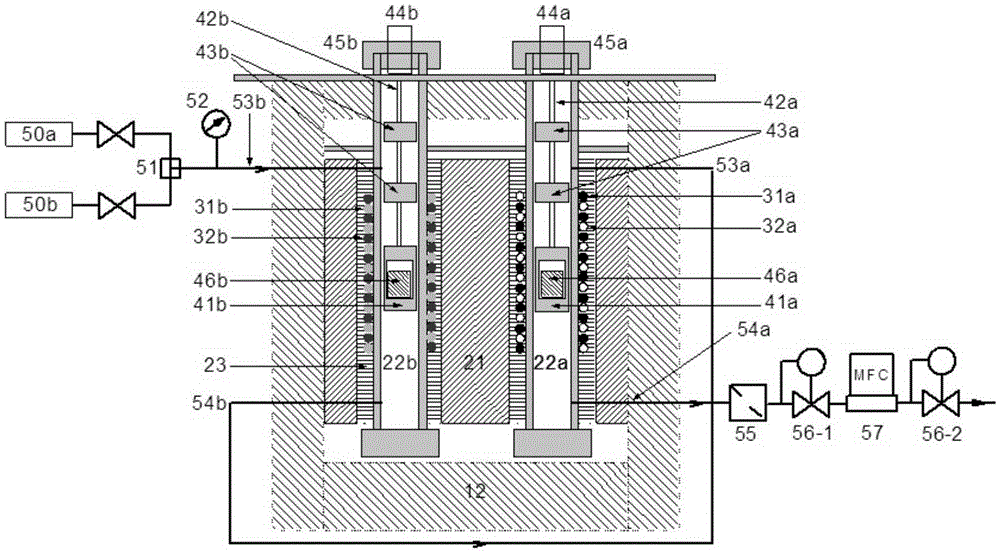

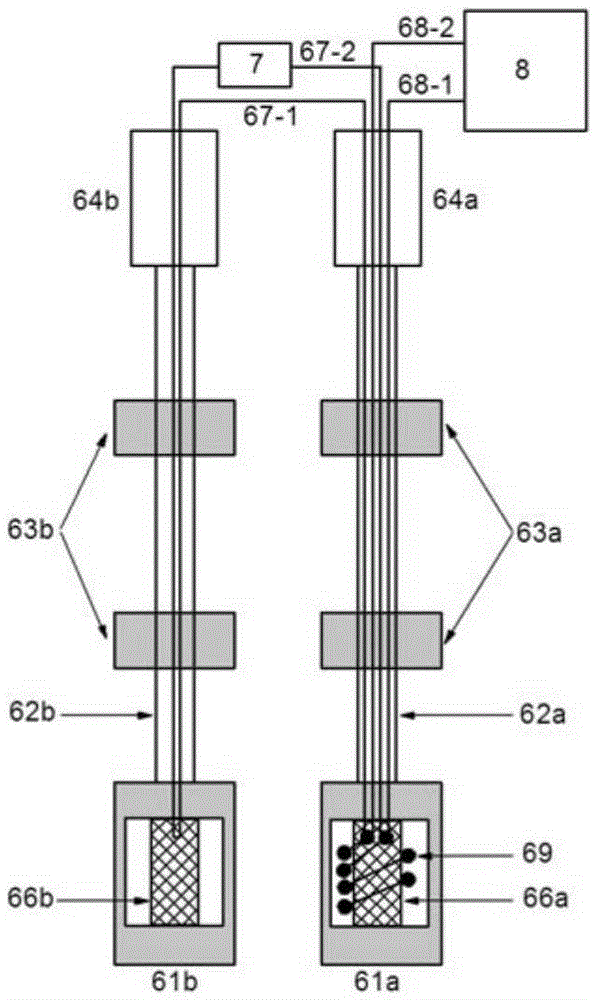

[0050] like figure 1 and figure 2 As shown, the thermal power measurement device provided by the present invention includes a constant temperature system, a calorimeter 2, a thermal measurement system, a reaction system, a gas supply system 5, a thermal calibration system, a program-controlled DC power supply 7, and a data acquisition and control system 8; wherein the constant temperature The system includes a temperature controller 11 and a tube-type constant temperature furnace 12 connected thereto; a calorimeter 2 is provided in the middle of the tube-type constant temperature furnace 12, and the calorimeter 2 includes a cylindrical copper-plated gold-plated soaking block 21. Two parallel and symmetrical cylindrical stainless steel reaction cell chambers 22a and reference cell chambers 22b are arranged in the thermal block 21, and the gap between the reaction cell chamber 22a, the reference cell chamber 22b and the soa...

Embodiment 2

[0059] Application of the thermal power measuring device of embodiment 2 and embodiment 1

[0060] Take the thermal power measurement of the oil sand oxidation process as an example to illustrate the use of the thermal power measuring device provided by the present invention:

[0061] Firstly, input different calibrated thermal power at room temperature to test the linear coefficient between it and the output voltage of the bridge, and this coefficient is the instrument constant of the thermal power measuring device. Change the input voltage signal at different temperatures to ensure that the instrument constant does not change with temperature.

[0062] Figure 4 It is the change of the input voltage signal with temperature when the instrument constant is constant from room temperature to 400°C. The abscissa is the temperature, and the ordinate is the input voltage. It can be seen that the voltage needs to increase with the temperature to ensure that the instrument constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com