Alloy material for aircraft seat framework

An alloy material and aircraft seat technology, applied in the field of aluminum-based alloys, can solve the problems of frequent use, easy damage, and a large amount of passenger seats in civil aviation, and achieve the effect of excellent compression resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

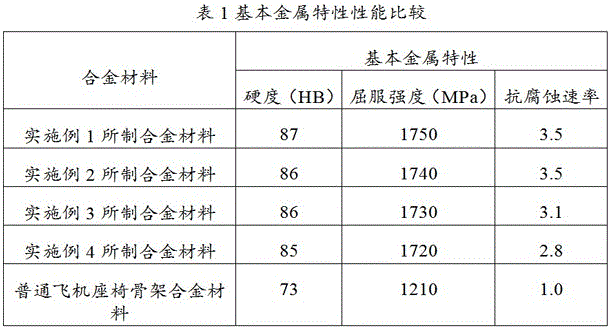

Examples

Embodiment 1

[0032] Raw material components:

[0033] Ti: 0.30%, Mn: 0.85%, P: 0.025%, Cu: 0.04%, Si: 0.45%, Cr: 13.0%, Ni: 7.0%, Zn: 0.18%, V: 0.27%, Co: 0.02%, W: 0.03%, Ce: 0.25%, Lu: 0.20%, and the rest is Al.

[0034] Prepared by:

[0035] Add the Al, Ti, Mn, P, Cu, Si, Cr, Ni, Zn, V, Co, W elemental substances to be smelted into the vacuum chamber of the water-cooled copper crucible, vacuumize, melt each elemental substance, and then add Ce, Lu, Al single substance, keep warm for 10 minutes, stir evenly, use centrifugal casting method to cast aircraft seat frame alloy material at 500°C, centrifugal speed 400rpm, and complete in 6 seconds; at 800°C, hot isostatic pressing 180MPa , holding the pressure for 2 hours to obtain the finished aircraft seat frame alloy material.

Embodiment 2

[0037] Raw material components:

[0038]Ti: 0.21%, Mn: 0.5%, P: 0.02%, Cu: 0.02%, Si: 0.25%, Cr: 12.0%, Ni: 3.0%, Zn: 0.13%, V: 0.2%, Co: 0.01%, W: 0.02%, Ce: 0.15%, Lu: 0.15%, and the rest is Al.

[0039] Prepared by:

[0040] Add the Al, Ti, Mn, P, Cu, Si, Cr, Ni, Zn, V, Co, W elemental substances to be smelted into the vacuum chamber of the water-cooled copper crucible, vacuumize, melt each elemental substance, and then add Ce, Lu, Al single substance, keep warm for 15 minutes, stir evenly, use centrifugal casting method to cast aircraft seat frame alloy material at 550°C, centrifugal speed 450rpm, and complete in 8 seconds; at 850°C, hot isostatic pressing 190MPa, Holding the pressure for 2.5 hours to obtain the finished aircraft seat frame alloy material.

Embodiment 3

[0042] Raw material components:

[0043] Ti: 0.35%, Mn: 1.05%, P: 0.03%, Cu: 0.05%, Si: 0.55%, Cr: 15.0%, Ni: 9.0%, Zn: 0.21%, V: 0.3%, Co: 0.03%, W: 0.04%, Ce: 0.30%, Lu: 0.30%, and the rest is Al.

[0044] Prepared by:

[0045] Add the Al, Ti, Mn, P, Cu, Si, Cr, Ni, Zn, V, Co, W elemental substances to be smelted into the vacuum chamber of the water-cooled copper crucible, vacuumize, melt each elemental substance, and then add Ce, Lu, Al single substance, keep warm for 20min, stir evenly, use centrifugal casting method to cast aircraft seat frame alloy material at 600°C, centrifugal speed 500rpm, complete in 10 seconds; at 900°C, hot isostatic pressing 210MPa, Holding the pressure for 3 hours to obtain the finished aircraft seat frame alloy material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com