Combined cutter head for rotary milling and crushing of road ice and snow layers

A combination of knife and ice and snow layer technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of not having the function of profiling with the ground, the decline of operation quality, and the short service life of the operation, so as to achieve good crushing, separation and cleaning operations Effect, high degree of generalization, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

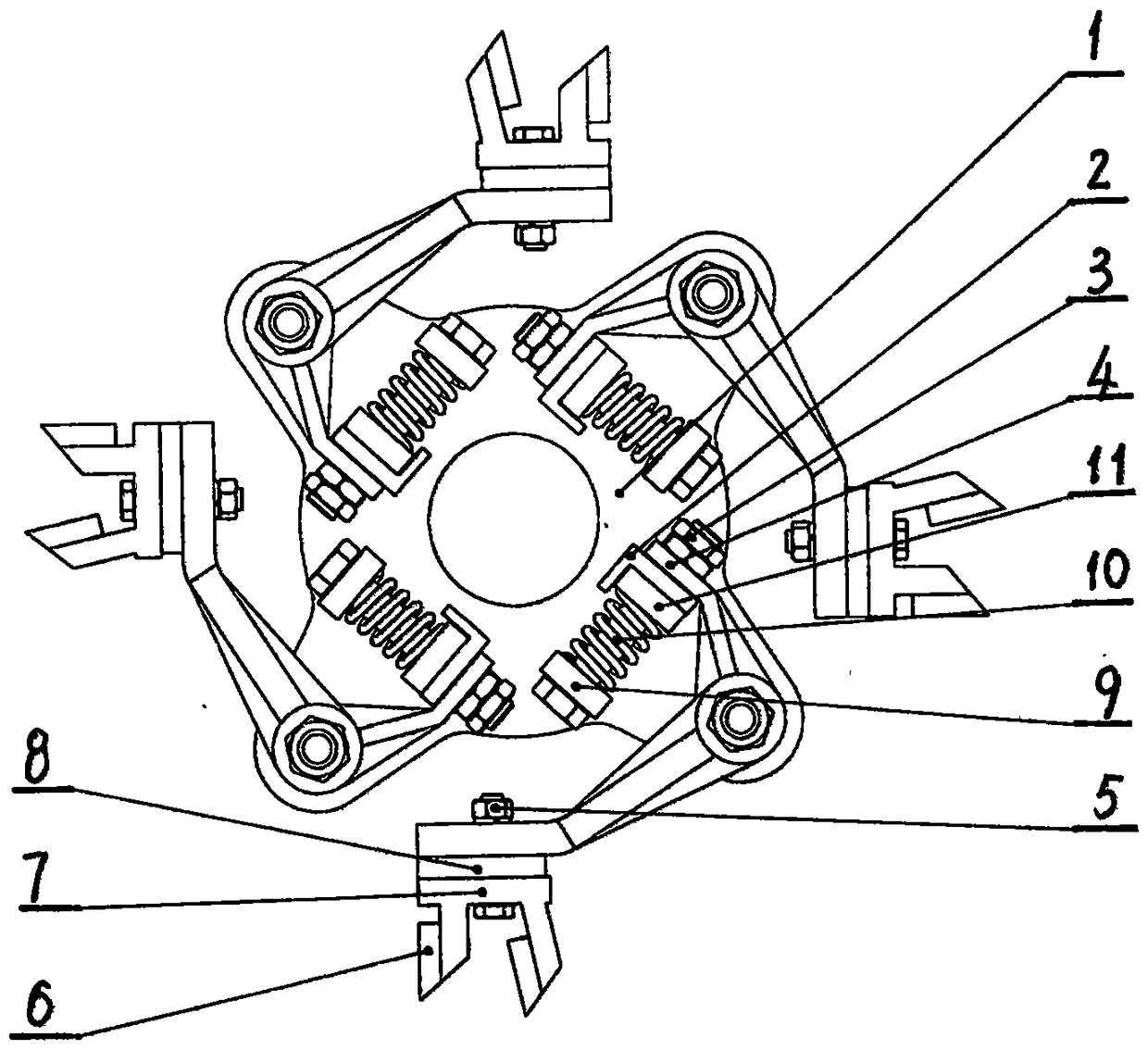

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A combination cutter head for rotary milling and crushing of ice and snow layers on the road surface, a rod seat plate 2 is fixed on one side of the cutter head body 1, and a spring seat A9, a pressure spring 10 and a spring seat B11 are sequentially fitted with a screw combination 3 that can move axially. Installed on the rod seat plate 2, the spring seat A9 is axially positioned on the screw assembly 3, the spring seat B11 is in contact with one side of the rod seat plate 2, and the two ends of the pressure spring 10 are respectively in contact with the spring seat A9 and the spring seat B11 Cooperate, on the same side of the fixed rod seat plate 2 on the cutter head body 1, the hinged installation swing rod 4 can be swung, one end of the swing rod 4 is sleeved on the screw rod assembly 3, and is connected with the rod seat The other side of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com