Gravity type self-anchorage connecting device and assembly method

A connecting device, gravity-type technology, applied in the direction of construction, building construction, etc., can solve the problems that cannot be used to connect building prefabricated parts, inconvenient to open, etc., to achieve the effect of ensuring durability, meeting long-term use, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

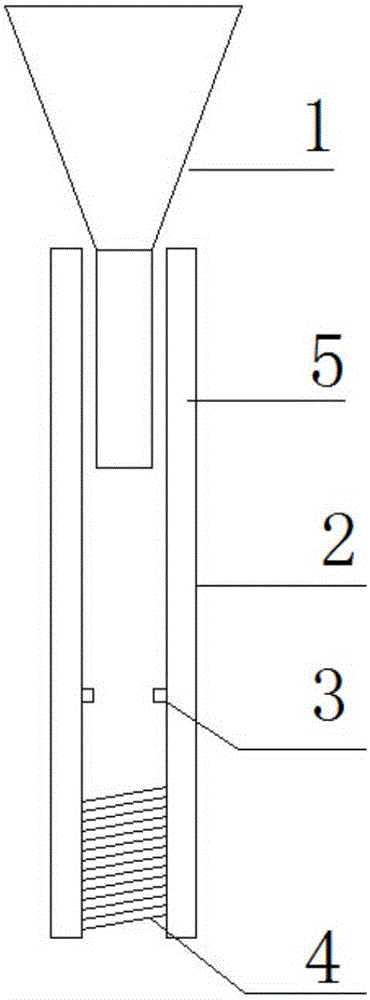

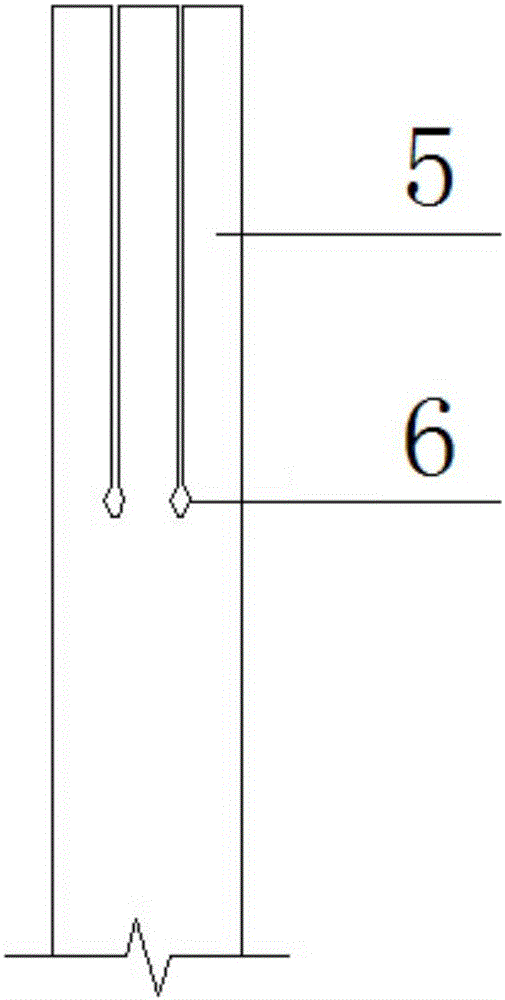

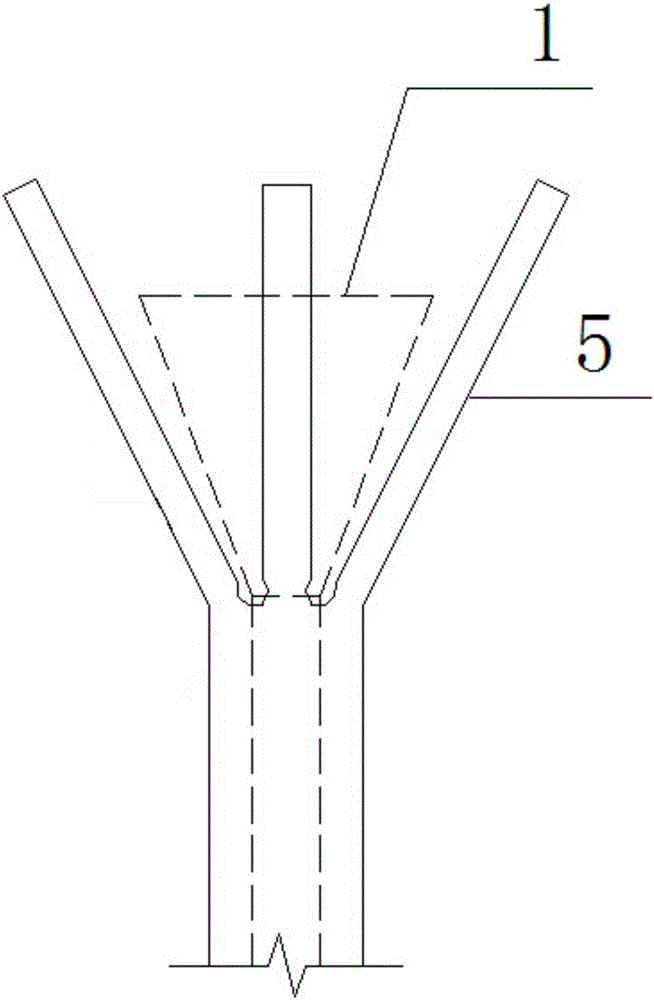

[0032] Embodiment 1: a kind of gravity type self-anchored connecting device, its structure is as follows Figure 1-3 Shown: includes a sleeve 2 with openings at both ends. The lower end of the sleeve 2 has a sleeve thread 4 for connecting the external steel bars of the building components. The upper end of the sleeve 2 is an expansion part 5, and an expansion part is inserted into the expansion part 5 head 1.

[0033] The expansion head 1 includes an integrally formed rod and a head, and the diameter of the largest part of the head is larger than the outer diameter of the sleeve 2 . And the head is in the shape of a truncated cone.

[0034] In order to facilitate expansion of the expansion part 5 , in this embodiment, a weakened part 6 is provided on the expansion part 5 .

[0035] From the perspective of accurate and convenient construction, a limiting protrusion 3 is provided inside the sleeve 2 , and the limiting protrusion 3 is located between the weakened portion 6 and ...

Embodiment 2

[0036] Embodiment 2: as Figure 4 As shown, a method for assembling two building components using the gravity-type self-anchoring connection device described in Embodiment 1, its main steps are as follows:

[0037] A, threading on the extended reinforcing bar of the first building component 7, so that the extending reinforcing bar 9 of the first building component 7 and the sleeve thread 4 at the lower end of the sleeve 2 form a thread pair;

[0038] B. Rotate the sleeve 2 until the outstretched steel bar is tight against the limit protrusion 3;

[0039] C, the expansion head 1 is placed in the reserved hole 10 of the second building component 8;

[0040] D. Loosen the second building component, so that the second building component 8 moves relative to the first building component by gravity, and the expansion head 1 is pressed down to move, so that the expansion part 5 expands and expands at the weakened part 6, and the expanded part The expansion part 5 forms a self-anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com