I-shaped steel and concrete combined structure member

A combined structure and concrete technology, which is applied in the direction of building components, building structures, columns, etc., can solve the problems of large amount of concrete pouring and insufficient mechanical performance, and achieve the effect of improving the level of industrialization, increasing the rate of prefabrication, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The in-line steel-concrete composite structural member of the present invention will be described in detail below with reference to the drawings and embodiments.

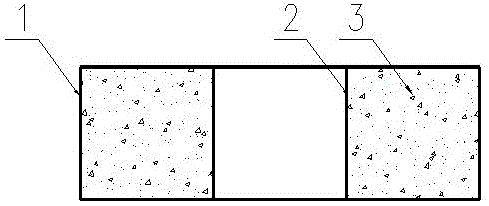

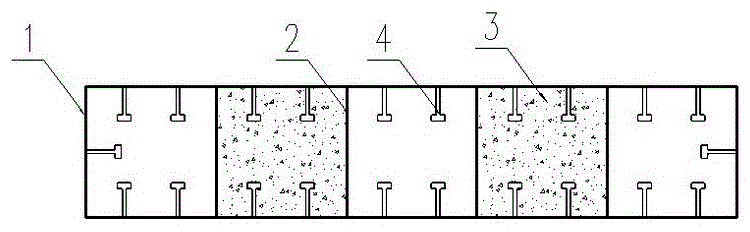

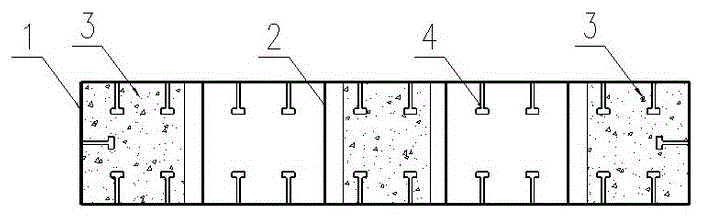

[0033] An embodiment of the in-line steel-concrete composite structural member proposed by the present invention, such as figure 1 , the structural members include steel members and concrete; the steel members include box-shaped steel parts 1 and connectors; the connectors are steel rods 2 connected to the long side steel plates of the box-shaped steel parts 1; the connectors divide the steel members into There are 3 areas, 2 areas are poured with concrete 3 (concrete is poured in a place other than the factory or the installation site, it is precast concrete), and the other area is not poured with concrete. In practical applications, the arrangement of the connectors of the steel members and the area filled with concrete are not limited to the embodiments shown in the accompanying drawings.

[0034] Another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com