Closed low temperature compressed air energy storage system and method

A technology of compressed air energy storage and air at room temperature, which is applied in the direction of variable volume pump components, liquid variable volume machinery, steam engine devices, etc., can solve problems such as strong environmental dependence, achieve broad application prospects, improve system efficiency, and improve The effect of energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

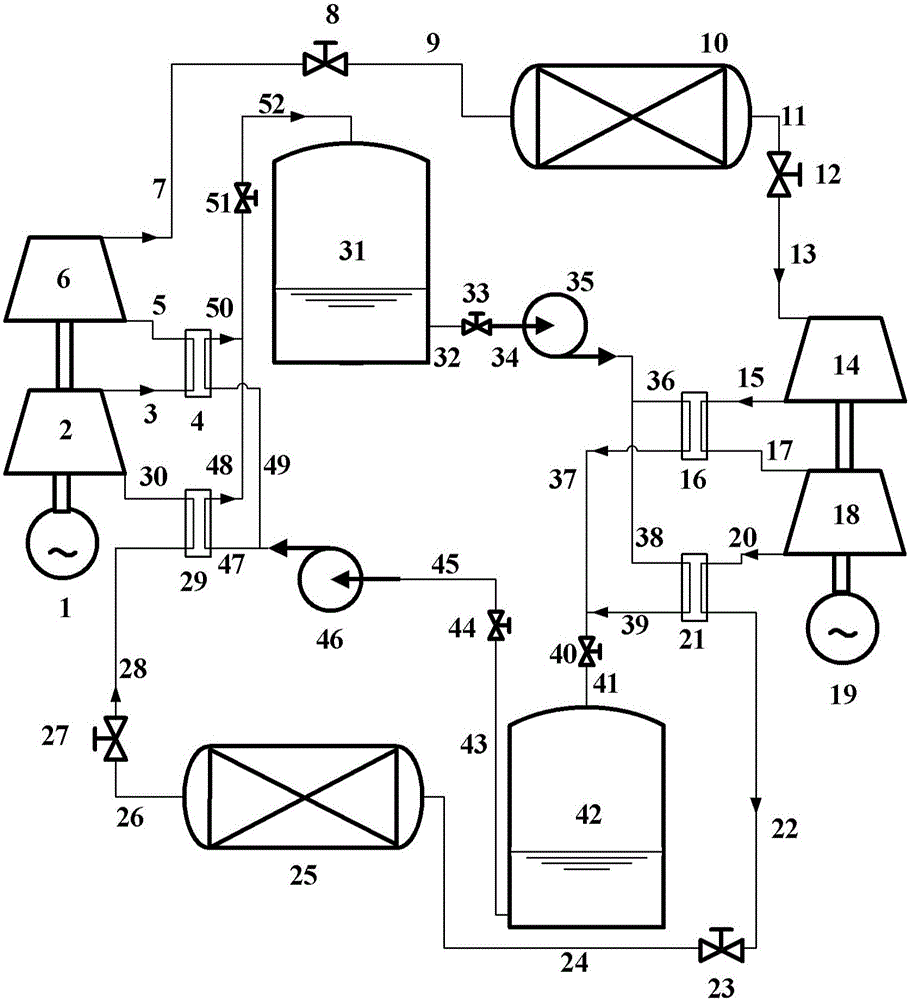

[0070] figure 1 Shown is Embodiment 1 of the closed low-temperature compressed air energy storage system of the present invention, which adopts two-stage compression, inter-stage cooling and two-stage expansion, and inter-stage heating. among them, figure 1 The reference signs in have the following meanings:

[0071] Motor 1, low pressure compressor 2, high pressure compressor 6, high pressure expander 14, low pressure expander 18, heat exchanger 4, 16, 21, 29, valve 8, 12, 23, 27, 33, 40, 44, 51 , Pipelines 3, 5, 7, 9, 11, 13, 15, 17, 20, 22, 24, 26, 28, 30, 32, 34, 36, 37, 38, 39, 41, 43, 45, 47, 48, 49, 50, 52, high pressure gas storage device 10, low pressure gas storage device 25, generator 19, normal temperature storage tank 31, low temperature storage tank 42, cryogenic pump 46, normal temperature pump 35, cold storage working medium and air.

[0072] The motor 1 is connected with the common drive shaft of the compressor unit, and the generator 19 is connected with the comm...

Embodiment 2

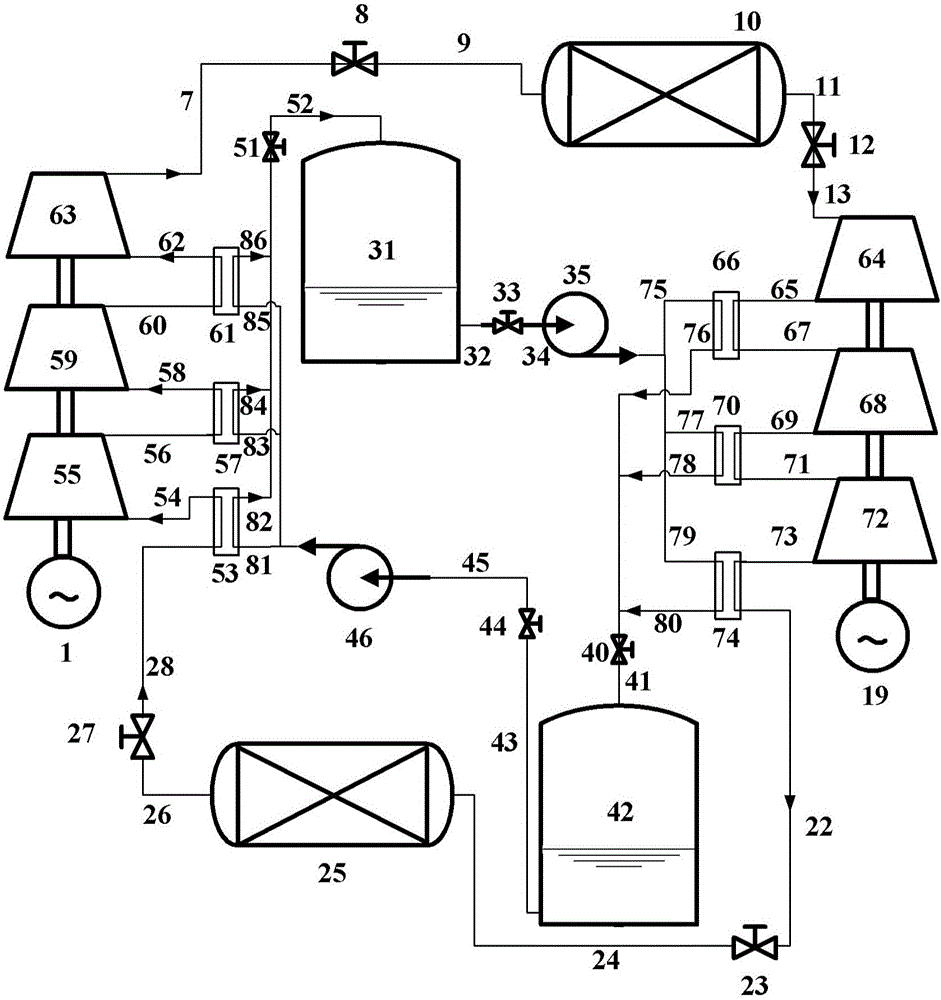

[0076] figure 2 Shown is embodiment 2 of the closed low-temperature compressed air energy storage system of the present invention. Its main structure is the same as that of embodiment 1, but it uses three-stage compression, inter-stage cooling, three-stage expansion, and inter-stage heating instead of embodiment 1. Two-stage compression, inter-stage cooling and two-stage expansion, inter-stage heating. among them, figure 2 The reference signs in have the following meanings:

[0077] Motor 1, low pressure compressor 55, medium pressure compressor 59, high pressure compressor 63, high pressure expander 64, medium pressure expander 68, low pressure expander 72, heat exchanger 53, 57, 61, 66, 70, 74, High pressure gas storage device 10, low pressure gas storage device 25, normal temperature storage tank 31, low temperature storage tank 42, cryogenic pump 46, normal temperature pump 35, valves 8, 12, 23, 27, 33, 40, 44, 51, pipeline 26, 28,54,56,58,60,62,7,9,11,13,65,67,69,71,73,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com