Injection type refrigeration cycle system and utilization method thereof

A circulating system and jet technology, applied in the field of jet refrigeration cycle system, can solve the problems of the overall size of the refrigeration cycle system increasing, the operation of the refrigeration cycle system being unstable, and the energy efficiency ratio decreasing, and achieving reduced size and strong practicability. , the effect of resolving pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

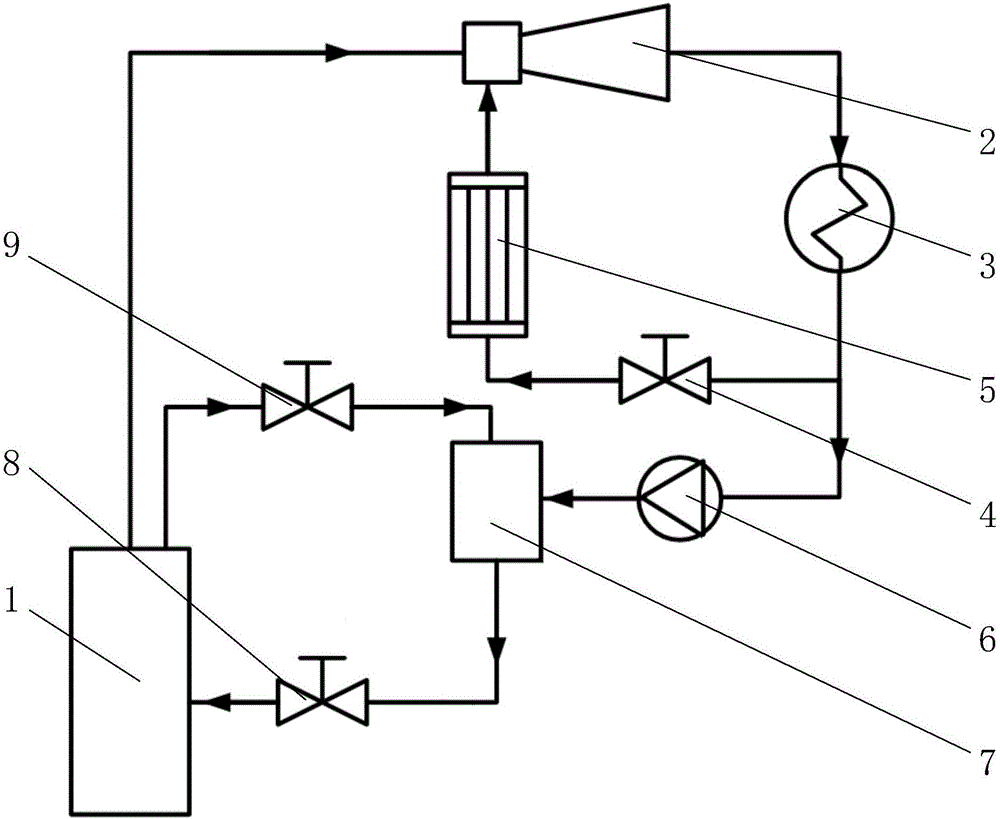

[0017] figure 1 The middle arrow is the flow direction of the working fluid.

[0018] Such as figure 1 As shown, the present invention provides a jet refrigeration cycle system, which includes a generator 1, an ejector 2, a condenser 3, a throttle valve 4, an evaporator 5, a circulation pump 6, a storage Liquid container 7, first valve 8 and second valve 9; wherein, generator 1, injector 2, condenser 3, circulation pump 6, liquid storage container 7 and first valve 8 are connected end to end in sequence to form a first circulation loop , the injector 2, the condenser 3, the throttle valve 4 and the evaporator 5 are connected end to end in order to form a second circulation loop, and the generator 1, the second valve 9, the liquid storage container 7 and the first valve 8 are connected end to end in order to form a The third circulation loop, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com