A device and method for measuring the electrowetting effect of micro-droplets

A micro-droplet and electro-wetting technology, applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve the problems of complex contact angle detection methods of micro-droplet electro-wetting effect and the influence of needle-shaped electrodes, and solve the problem of easy detachment Electrode problems, improved measurement accuracy, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

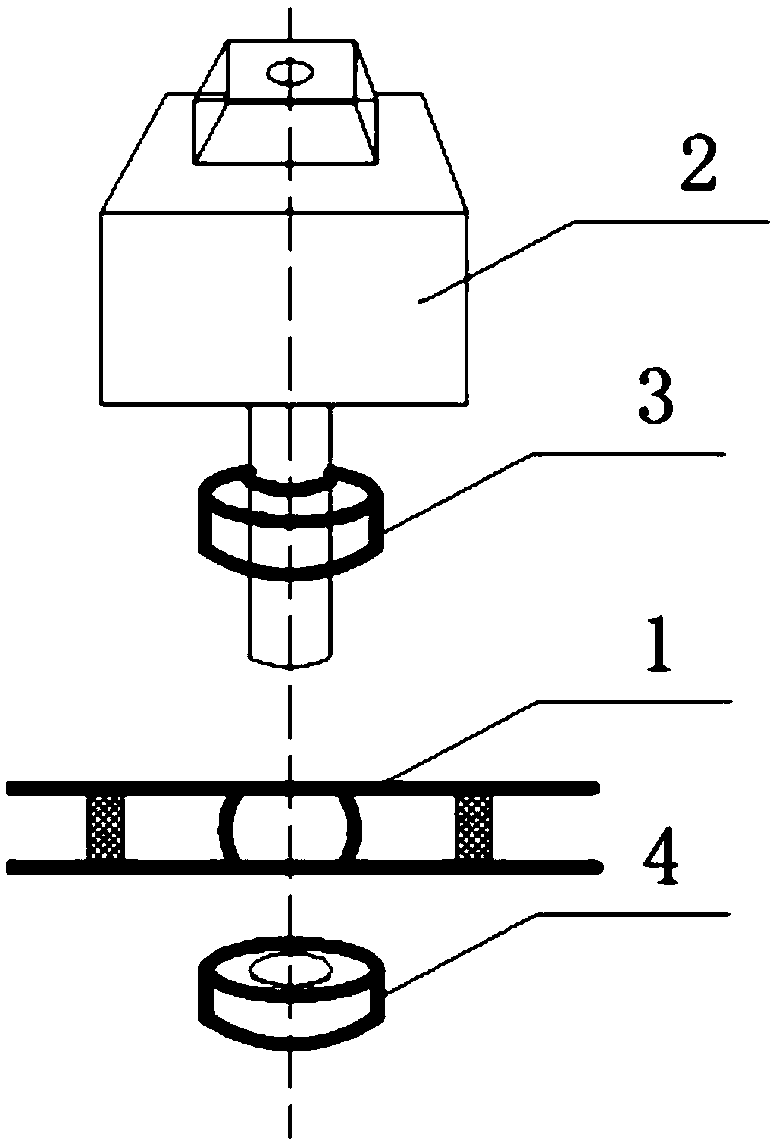

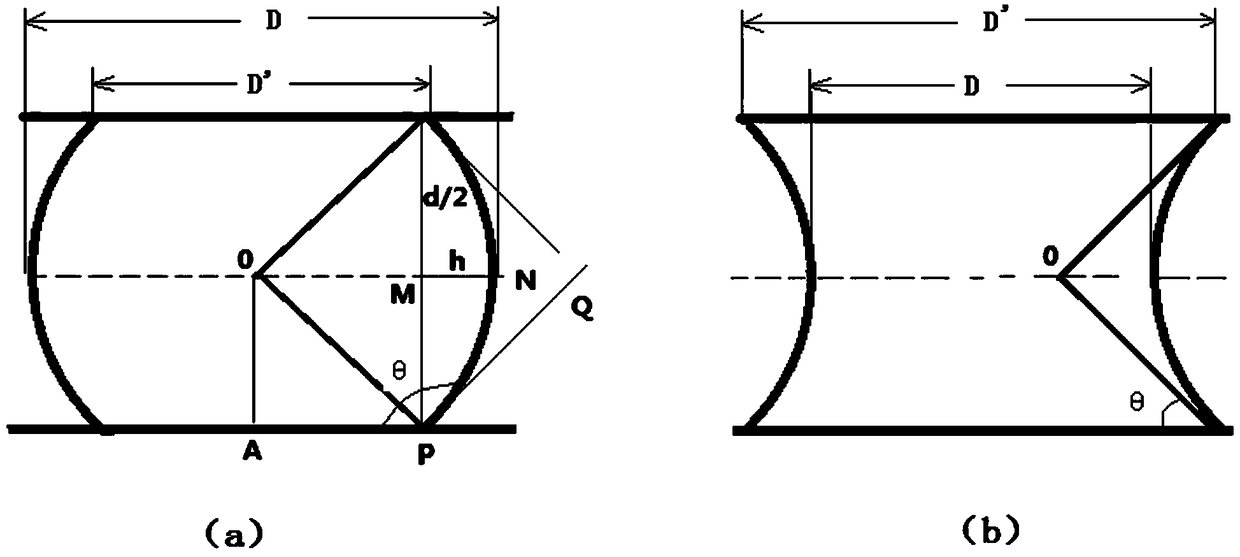

[0026] Determine the wettability of solid surfaces. Such as figure 1 , turn on the reflective light source 3, at this time the circle image of the contact surface between the liquid and the upper cover is the most obvious, and measure the diameter of the circle to be D'; turn on the transmission light source 4, at this time the microscopic system can clearly capture the circle image, The two diameters are measured as D and D' respectively, and the infiltration of the solid surface can be judged by comparing the sizes of D and D'. When D>D', the contact angle θ is greater than 90 degrees, that is, no wetting, such as image 3 (a); When D image 3 (b). The wetting angle is given by the formula Get it.

Embodiment 2

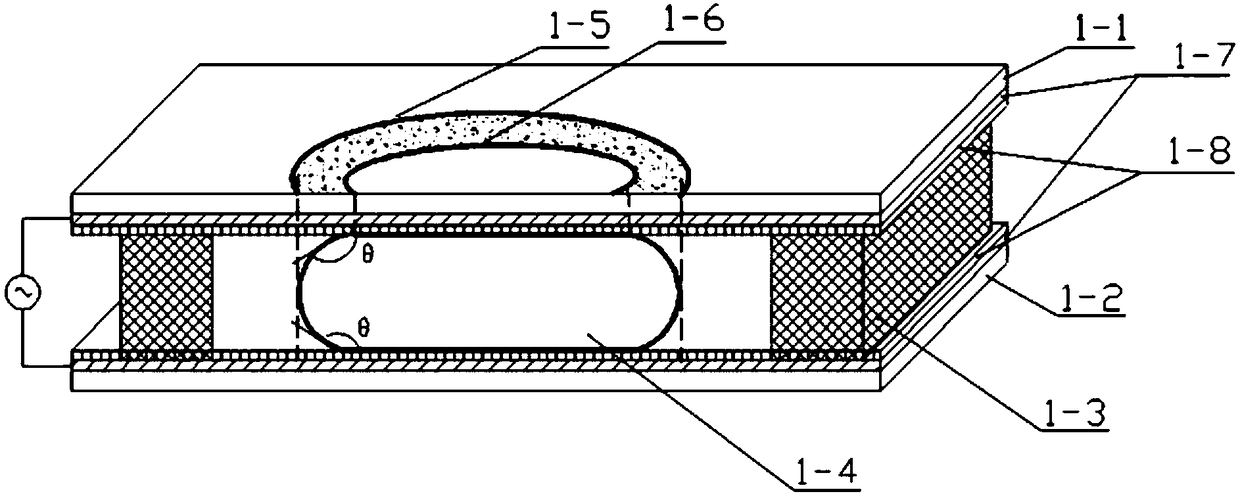

[0028] Measure the contact angles of two liquids with the same solid surface. Such as figure 2, replace the supporting columns 1-3 with sealing rings of thickness d, and pour transparent insulating oil that is immiscible with it around the conductive liquid droplet, and the oil can obviously increase the initial contact angle. In the same way, measure the parameters such as D, D', etc., and bring them into The contact angle can be found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com