Micro-fluid test card

A test card and microfluidic technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of not being able to avoid storage liquid well, complex structure, and liquid flow rate that cannot be controlled according to user needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

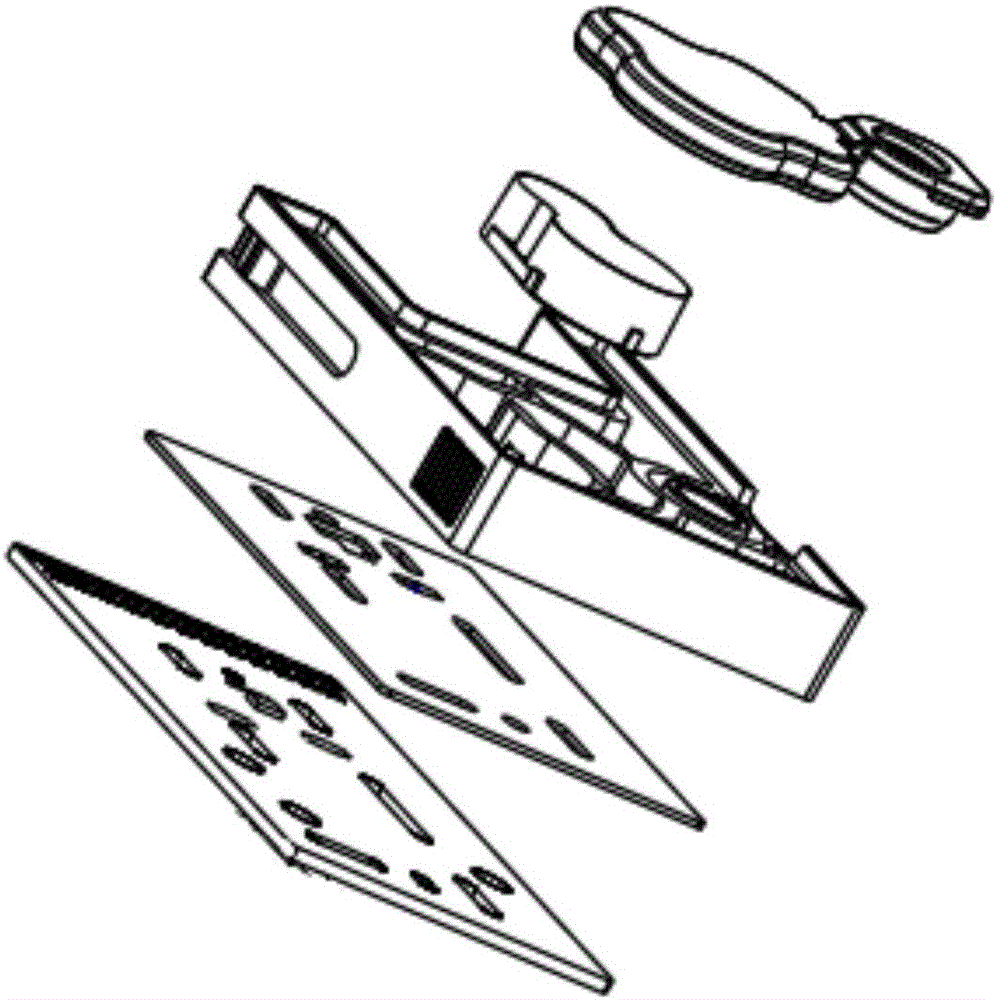

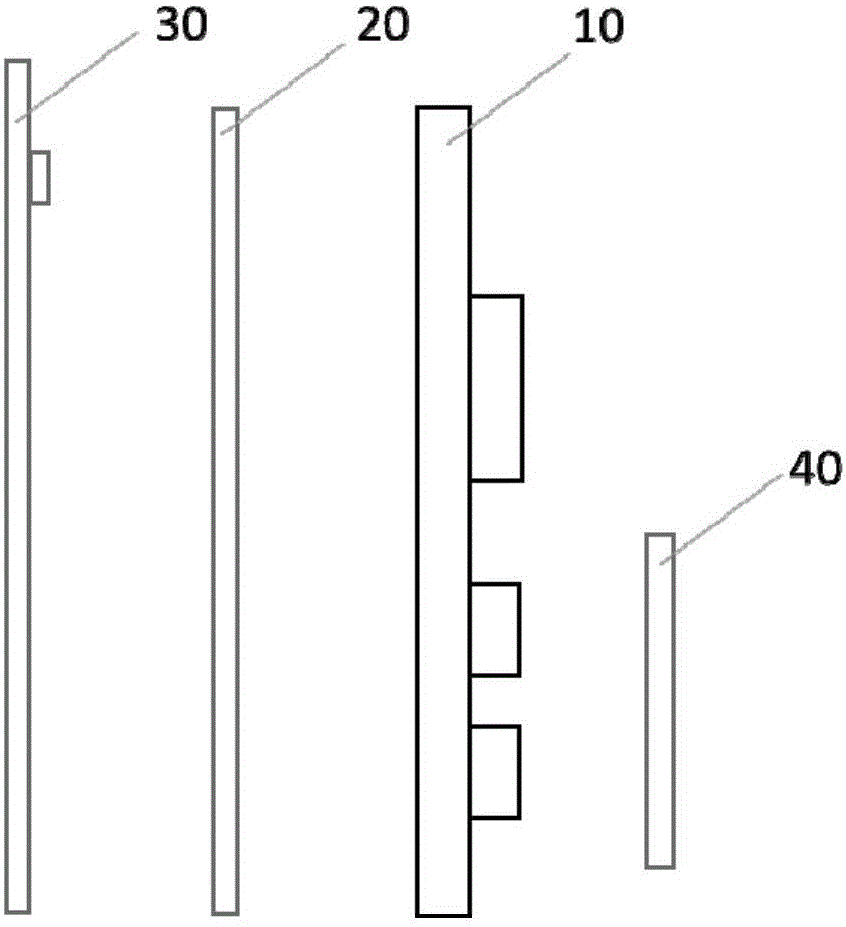

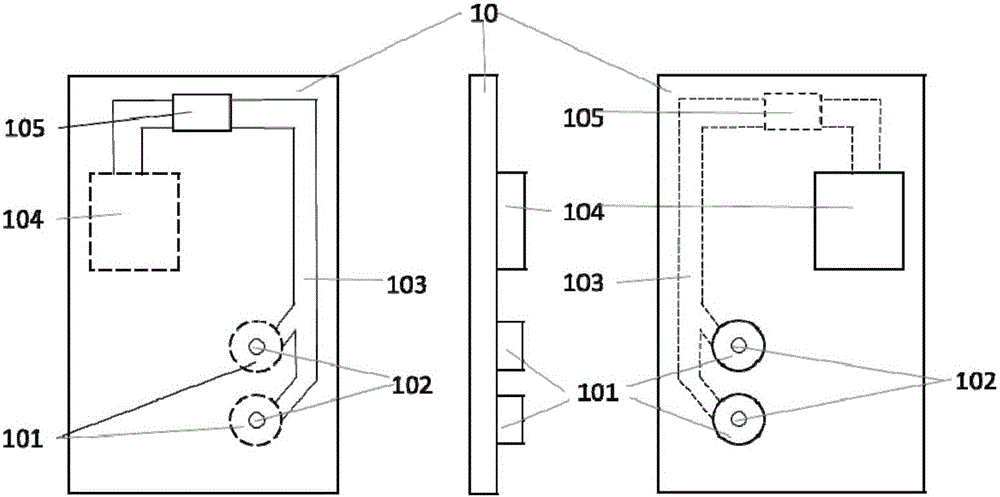

[0056] Such as Figure 2 to Figure 4 As shown, the present invention discloses a microfluidic test card, the test card includes a reaction chamber and a microchannel layer 10, a microchannel sealing layer 20 and a detection layer 30; the microfluidic test card further includes: At least one liquid storage chamber and pump chamber 101 of the microchannel layer 10; the first liquid storage chamber sealing layer for sealing the liquid storage chamber and pump chamber 101 and isolating the microchannel 103 that can be communicated; located in the first liquid storage chamber The opposite side of the sealing layer is used to seal the second liquid storage sealing layer of the liquid storage chamber and the pump chamber 101; the waste liquid pool 104 is convex in the reaction chamber and the microchannel layer 10 and communicates with the reaction chamber 105; Second, the pump chamber sealing layer 40 outside the liquid storage sealing layer. The microchannel 103 and the reaction c...

Embodiment 2

[0062] Such as Figure 6 As shown, the present invention discloses a microfluidic test card, which includes a reaction chamber and a microchannel layer 50, a microchannel sealing layer and a detection layer; the microfluidic test card further includes: protruding from the reaction chamber and microchannel At least one liquid storage chamber and pump chamber 60 of layer 50; the first liquid storage chamber sealing layer for sealing the liquid storage chamber and pump chamber 60 and isolating the microchannel that can be communicated; The side is used to seal the second liquid storage sealing layer of the liquid storage chamber and the pump chamber 60; the waste liquid pool 501 protrudes from the reaction chamber and the microchannel layer 50 and communicates with the reaction chamber; and, located in the second liquid storage seal Layer outside the pump chamber seal layer. The microchannel and the reaction chamber are located on the same side of the reaction chamber and the mi...

Embodiment 3

[0069] Such as Figure 7 As shown, the present invention discloses a microfluidic test card, which includes a reaction chamber and a microchannel layer 70, a microchannel sealing layer 80 and a detection layer 90; the microfluidic test card further includes: At least one liquid storage chamber and pump chamber 701 of the microchannel layer 70; the first liquid storage chamber sealing layer for sealing the liquid storage chamber and pump chamber 701 and isolating the microchannel that can be communicated; The opposite side of the layer is used to seal the second liquid storage sealing layer of the liquid storage chamber and the pump chamber 701; the waste liquid pool is protruding from the reaction chamber and the microchannel layer 70 and communicated with the reaction chamber; and, located in the second liquid storage The pump chamber sealing layer 85 outside the sealing layer. The microchannel and the reaction chamber are positioned on the same side of the reaction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com