A surface resistance test probe and its test device and surface resistance test method

A surface resistance and testing device technology, applied in the direction of measuring resistance/reactance/impedance, measuring device, measuring electrical variables, etc., can solve the problems of resistance deviation from normal resistance, large mechanical pressure, different resistance performance, etc., to achieve good test results, Avoid contact and ensure good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

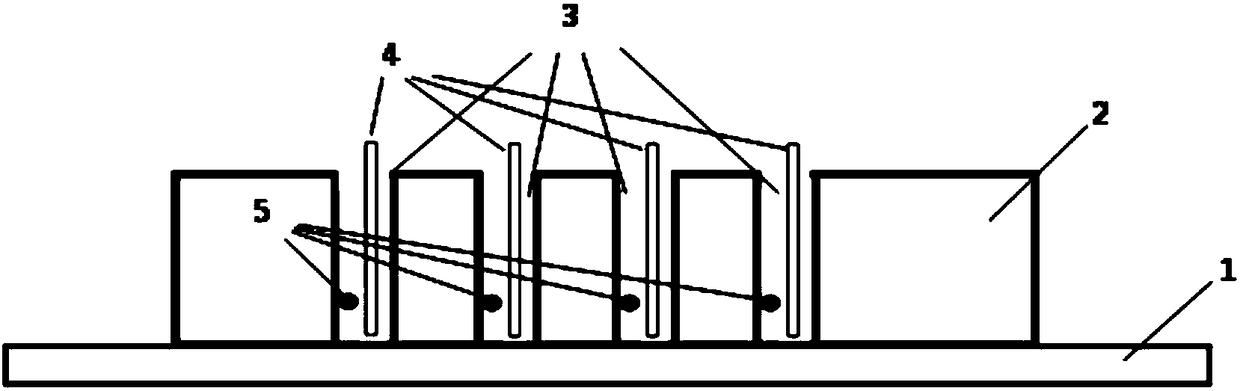

Embodiment 1

[0041] Example 1: A plexiglass plate with a length of 5 cm x a width of 3 cm x a thickness of 1 cm is placed on the surface of the test sample 1 as an insulating module 2. In the middle of the plexiglass plate, there are four Φ5 mm, center-to-center distances of 10 mm, arranged up and down in a straight line. Through-hole 3, put four copper wires, that is, metal wire 5, into the through-hole 3 from above the through-hole 3, and the length of the copper wire that penetrates into the through-hole 3 is 8 mm, and connect the four copper wires to a resistance tester On the instrument, the connection method is: 5 metal wires connected to the two through holes 3 outside the four through holes 3 are connected to the current terminal of the resistance tester, and 5 metal wires connected to the two through holes 3 in the middle of the four through holes 3 are connected to the current terminal of the resistance tester. The voltage terminal of the resistance tester. Open the resistance te...

Embodiment 2

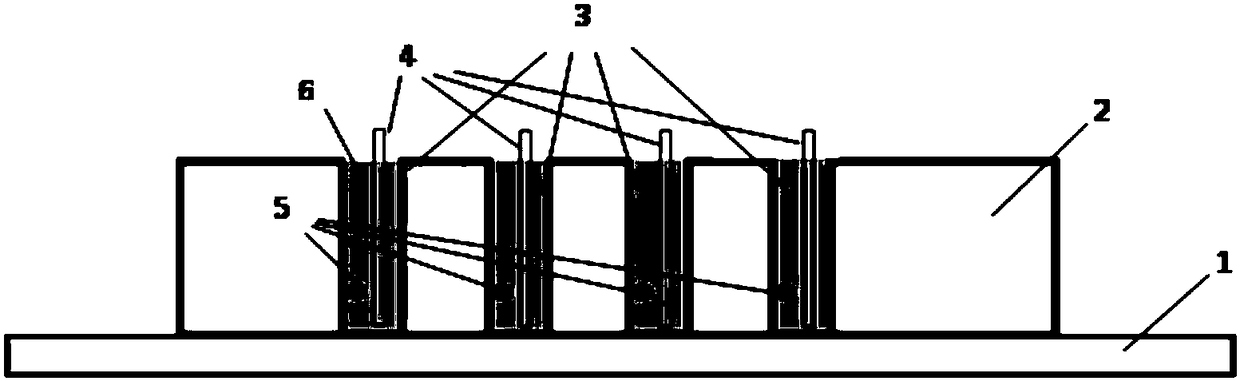

[0042] Embodiment 2: A ceramic plate with a length of 6 cm × width of 4 cm × thickness of 2 cm is placed on the surface of the test sample 1 as the insulating module 2. In the middle of the ceramic plate, there are four through holes of Φ3 mm and a center distance of 5 mm arranged in a straight line. Hole 3, put four copper wires, that is, metal wires 5, into the through hole 3 from above the through hole 3, and the length of the copper wires that go deep into the through hole 3 is 15 mm, and connect the four copper wires to a resistance tester , the connection method is: the metal wires connected to the two through holes 3 outside the four through holes 3 are connected to the current terminal of the resistance tester, and the metal wires connected to the two through holes in the middle of the four through holes 3 are connected to the resistance tester. voltage terminal. Turn on the resistance tester, inject mercury 6 into the four through holes 3 until the liquid level of mer...

Embodiment 3

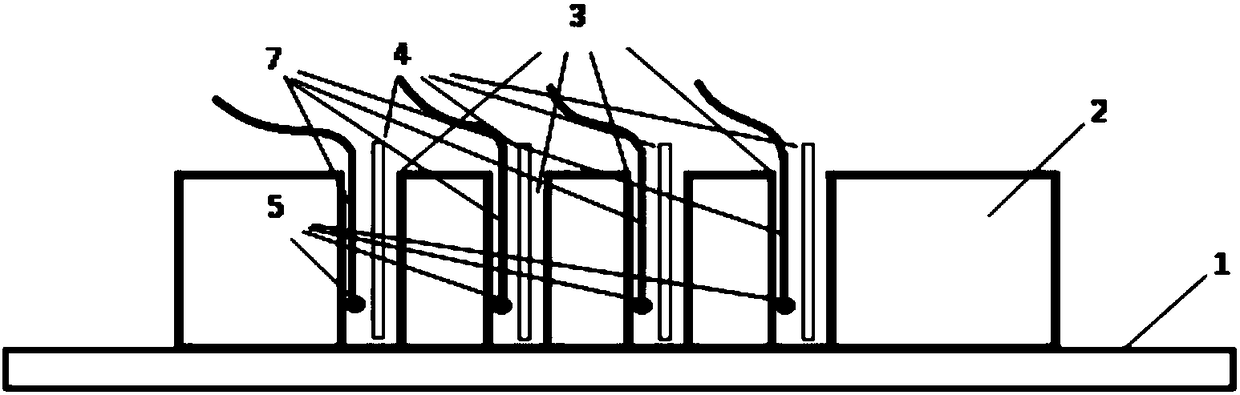

[0043] Example 3: A polyaniline board with a length of 5 cm x width of 2 cm x a thickness of 1.5 cm is placed on the surface of the test sample 1 as the insulating module 2. In the middle of the polyaniline board, there are four sides with a length of 4 mm and a center distance of 6 mm, arranged in a straight line The through-hole 3 that penetrates up and down is drilled from the back of the polyaniline board and then put four aluminum wires, that is, the metal wire 5, into the through-hole 3 from the side of the through-hole 3, and the length of the aluminum wire that penetrates into the through-hole 3 is 3mm, connect these four aluminum wires to a resistance tester. The metal wire 5 connected to the two through holes 3 in the middle of the hole 3 is connected to the voltage end of the resistance tester. Turn on the resistance tester, inject mercury 6 into the four through holes 3 until the liquid level of mercury 6 is flush with the surface of the polyaniline board, and reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com