XLPE (Cross Linked Polythylene) insulation aging estimation method based on different frequency and dielectric loss ratios

A technology for insulation aging and state evaluation, which is applied in the direction of testing dielectric strength, measuring devices, instruments, etc., can solve the problems of not truly reflecting the system state, large dispersion of test data, etc., and reduce the influence of system errors and external environments , Eliminate aging unevenness, and facilitate engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with specific embodiments.

[0023] The method of effectively evaluating the aging state of XLPE insulation based on the relative ratio of the measured values of dielectric loss at two characteristic frequencies proposed by the present invention includes the following steps:

[0024] Step 1: Prepare the slice sample;

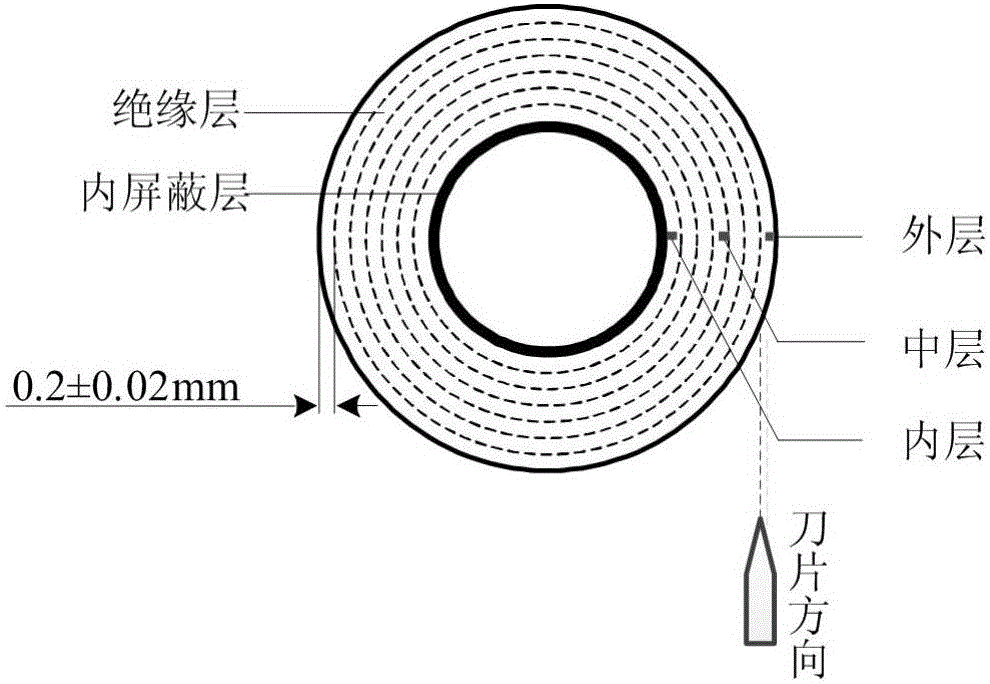

[0025] Take new 110kV AC XLPE cables that have been operating on site for 16 and 24 years as the object. Take a cable segment with a length of about 100mm, remove the conductor core and strip all parts except the insulation shield, and perform circular cutting along the cable circumference. (Such as peeling fruit peels), cut the insulating layer ring into slices with a thickness of about (0.2±0.02) mm, and divide the insulation into three parts along the radial direction, called inner layer, middle layer, and outer layer. figure 1 As shown, for each type of cable, cut 3 samples at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com