Method for improving efficiency of organic polymer photovoltaic cells

A photovoltaic cell, polymer technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as low photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

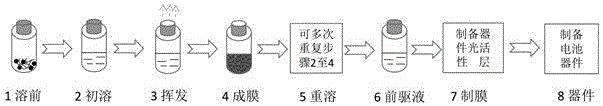

Method used

Image

Examples

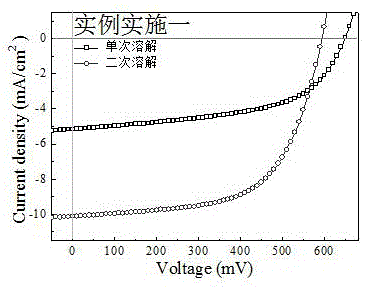

Embodiment 1

[0015] According to the above-mentioned content of the invention, the P3HT:PCBM photovoltaic system was selected as the experimental object, and the P3HT:PCBM (mass ratio 1:1, the concentration was both 20 mg / ml) was first dissolved in chloroform solvent, stirred magnetically for 8 h, and then the dissolution bottle was opened, Let the chloroform evaporate naturally. Then use o-dichlorobenzene to dissolve the photoactive film in the bottle, and stir it magnetically for more than 12 h to prepare the precursor solution for the formal photoactive layer film.

[0016] After cleaning the ITO conductive glass substrate, spin-coat ZnO functional layer on its surface, and then apply the prepared solution on the surface of ZnO by spraying method (the dosage is 20 ul, and the spin-coating is carried out in two steps: 600 r / min). , 6 s and 1200 r / min, 20 s). Then, the obtained photoactive layer film was naturally air-dried. After drying, MoO was successively evaporated on the surface o...

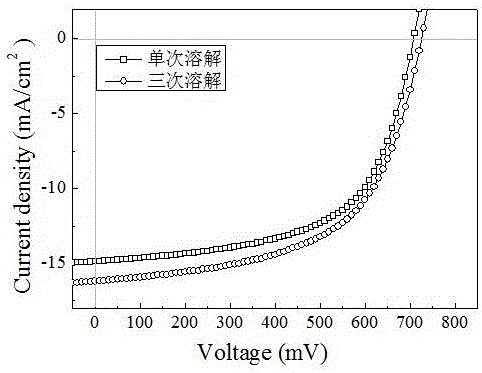

Embodiment 2

[0018] According to the above-mentioned content of the invention, select PTB7:PC 71 The BM photovoltaic system was used as the experimental object, and PTB7:PC was first dissolved in chloroform solvent. 71 BM (mass ratio 1:1.5, PTB7 concentration is 10 mg / ml, PC 71 BM concentration is 15 mg / ml), stir magnetically for 8 h, then open the dissolution bottle and let the chloroform evaporate naturally. Dissolve the photoactive film in the bottle with dichloroethane and stir magnetically for more than 8 h. Finally, a mixed solvent of chlorobenzene and 1,8-diiodooctane (97%: 3%) was used to dissolve PTB7:PC 71 BM to prepare the precursor solution for making the formal photoactive layer thin film.

[0019] After cleaning the ITO conductive glass substrate, spin-coat the ZnO functional layer on its surface, and then apply the above-prepared solution to the surface of ZnO by spin-coating method (amount of 20 ul, spin-coating process: 850 r / min, 50 s). Then, the obtained photoactive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com