Anti-misoperation locking system and method for power plant

A technology for preventing false locks and power plants. It is applied to electrical components, circuit devices, AC network circuits, etc., and can solve the problems of missing displacement signals and no prompt function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below:

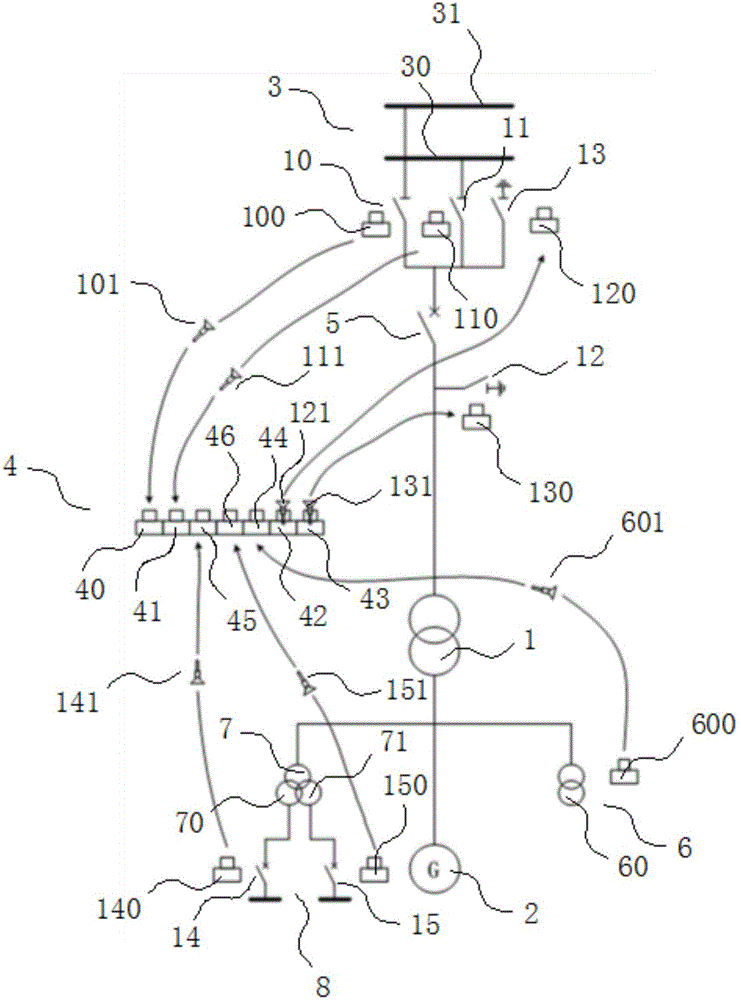

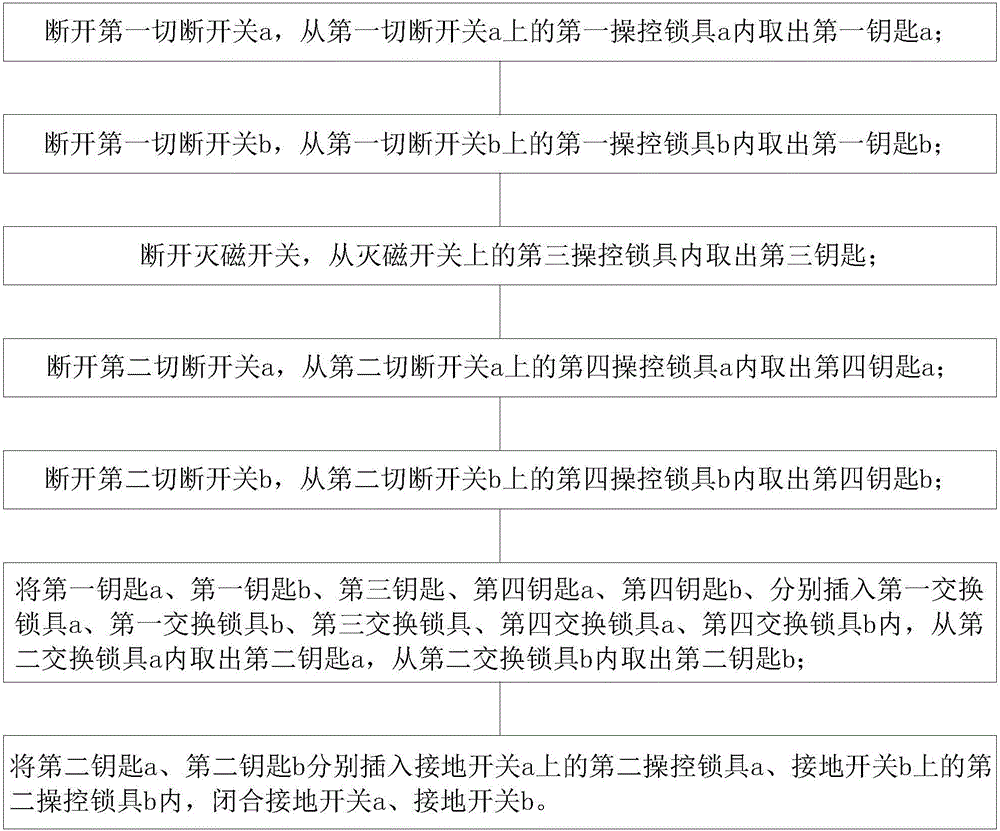

[0035] Such as figure 1 As shown, the power plant anti-misoperation locking system described in this embodiment includes a step-up transformer 1, a generator 2, a transmission network 3 and a key exchange box 4, the low-voltage side of the step-up transformer 1 is connected to the generator 2, The transmission network 3 includes a first single bus 30 and a second single bus 31, the first single bus 30 and the second single bus 31 are respectively connected to the high voltage side of the step-up transformer 1, and the transmission network 3 is connected to the grounding switch There is a first cut-off switch between them. The first cut-off switch includes a first cut-off switch a10 and a first cut-off switch b11. The first cut-off switch a10 is arranged on the high-voltage side of the first single bus bar 30 and the step-up transformer 1. Between, the first cut-off switch b11 is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com