An assembly device for motor rotor and stator

A motor rotor and assembly device technology, which is applied in the direction of centering/balancing the rotor, etc., can solve the problems of cumbersome operation, low assembly efficiency, and injury to parts and personnel, and achieve the effects of ensuring accuracy, high assembly efficiency, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

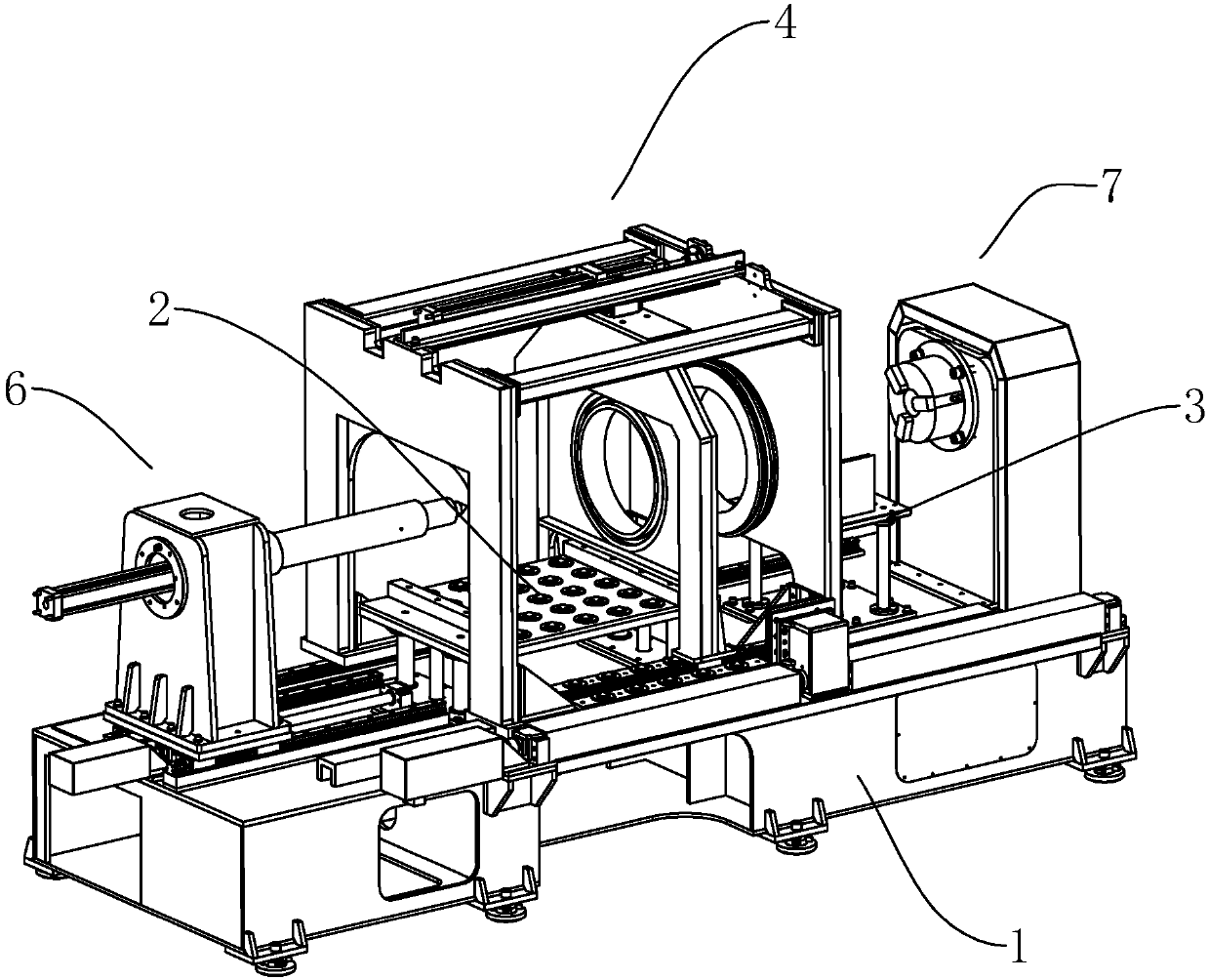

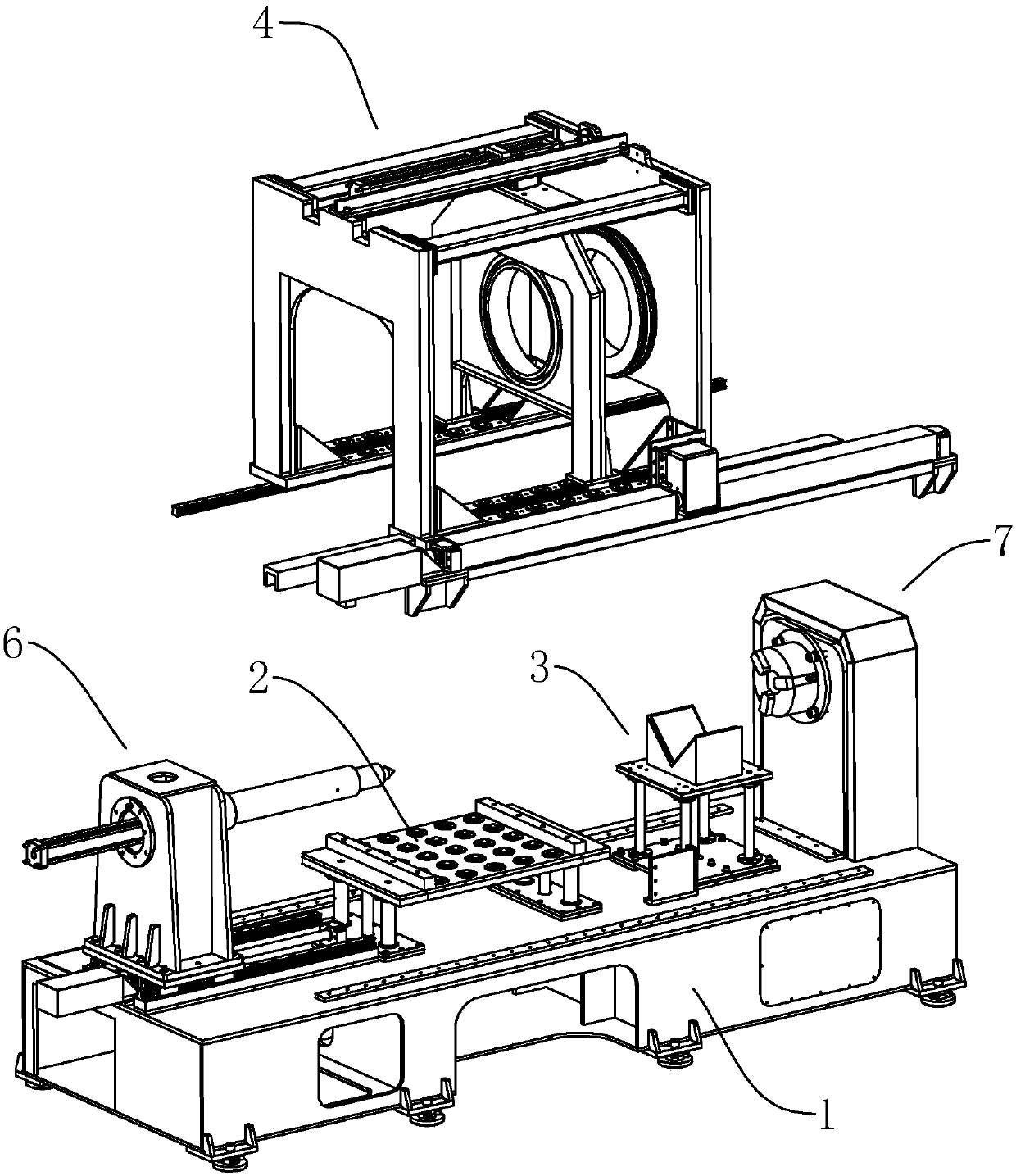

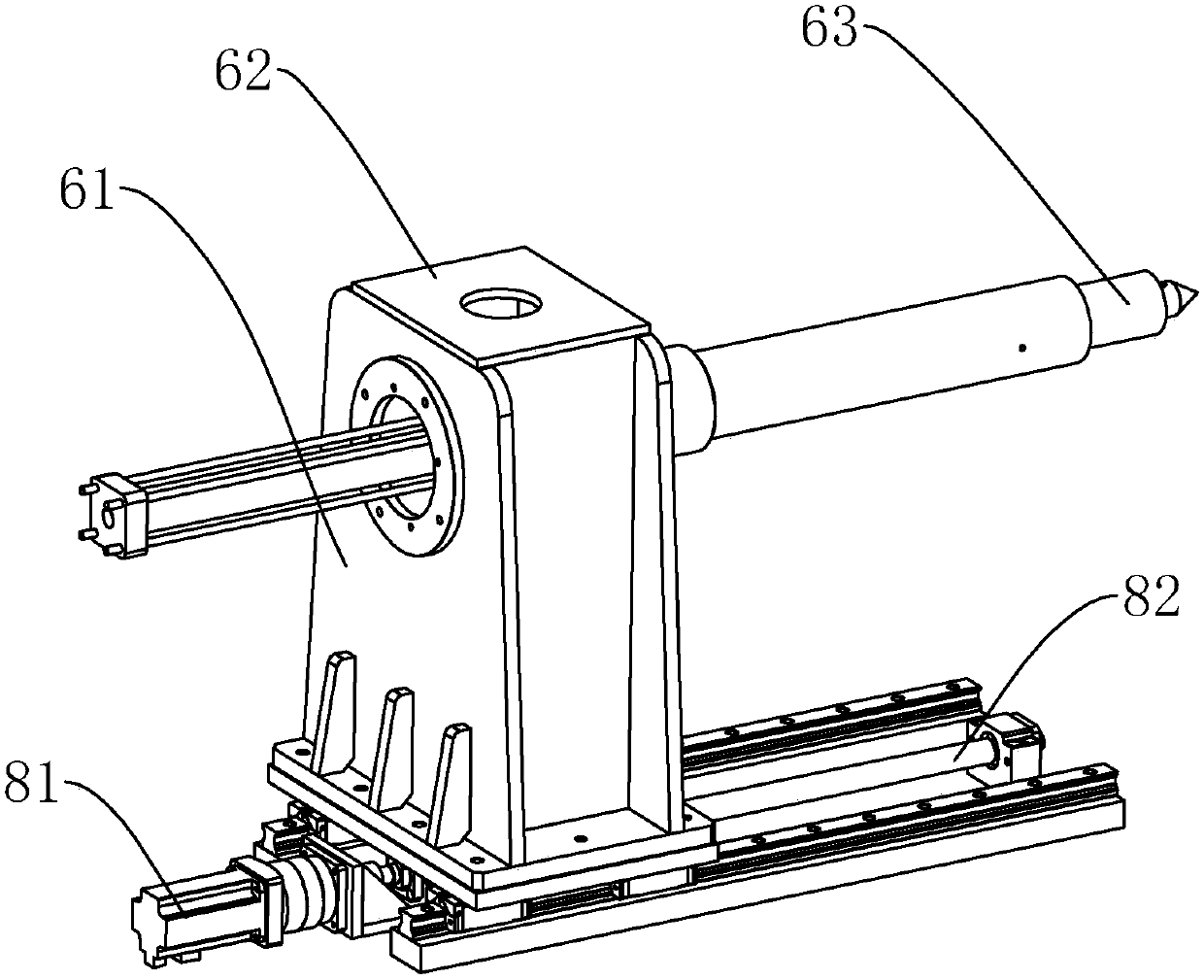

[0030] refer to Figure 1 to Figure 11 , Figure 1 to Figure 11 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, an assembly device for a motor rotor and a stator includes a machine base 1, a stator fixing mechanism, a rotor fixing mechanism, and can drive the stator fixing mechanism and the rotor fixing mechanism to move relatively. The machine base 1 adopts an integral welded bed, which has high rigidity and good stability. There is a channel specially designed for the assembly line at the bottom of the base 1;

[0031] The stator fixing mechanism includes a stator feeding device and a stator frame 4. A stator pressing mechanism is arranged in the stator frame 4. The stator pressing mechanism includes a pressing plate 51 and a pressing drive mechanism. The stator frame 4 It is a frame structure, which includes a front loading plate 41 opposite to the pressing plate 51, the pressing plate 51 and the front loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com