motor control unit

A control device and motor technology, applied in the direction of speed adjustment of multiple motors, control using feedback, etc., can solve problems such as vibration, inability to fully improve the control response of the servo controller, and difficulty in ensuring the synchronization accuracy of multiple motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

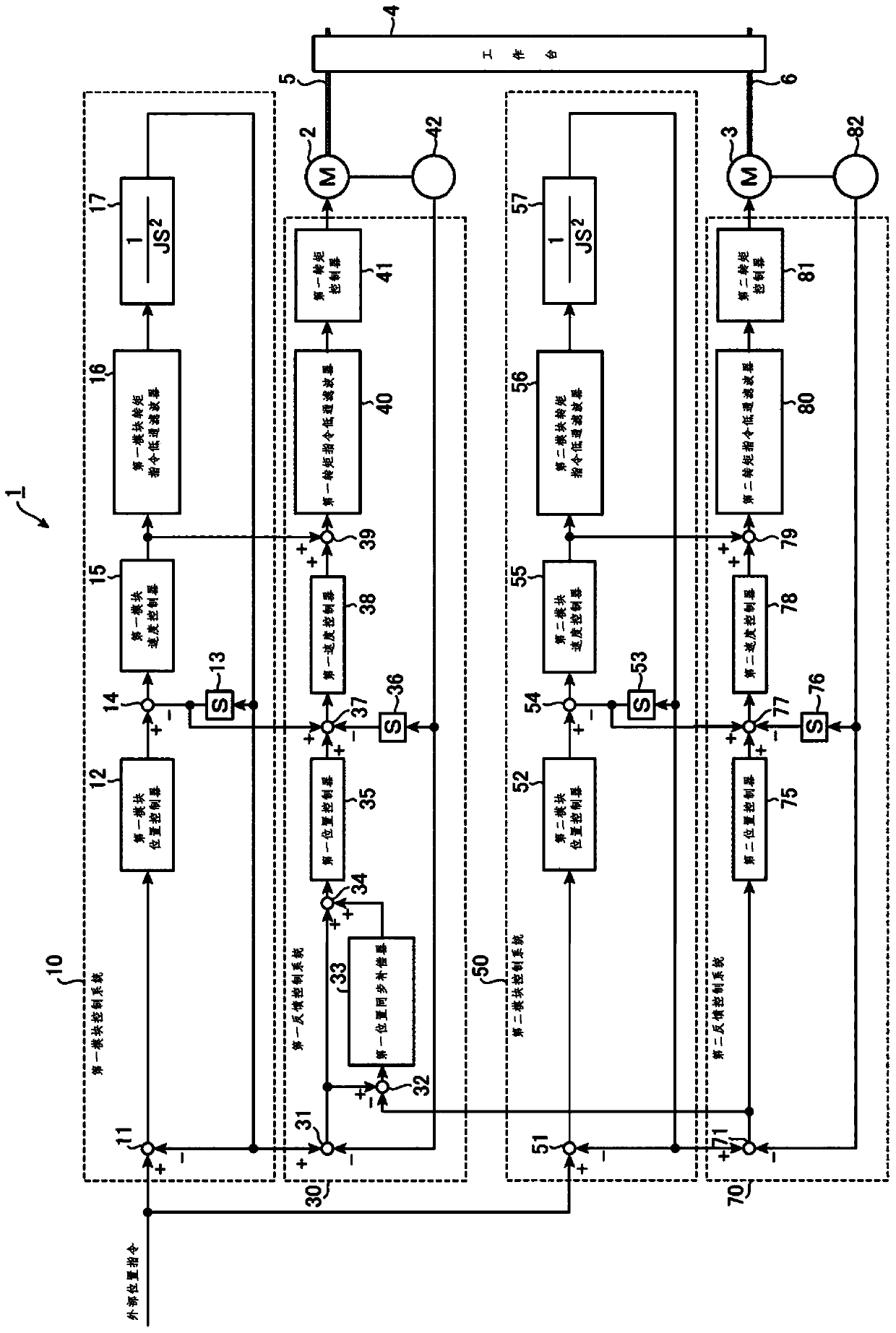

[0079] figure 1 It is a block diagram of the motor control device 1 according to the first embodiment of the present invention. exist figure 1 In the motor control device 1 shown, two motors, the first motor 2 and the second motor 3, drive one movable part in common. Accordingly, the motor control device 1 can specify the position of the movable portion at high speed and with high precision.

[0080] Such as figure 1 As shown, the motor control device 1 has: a first module control system 10 , a first feedback control system 30 , a second module control system 50 and a second feedback control system 70 .

[0081] An external position command indicating the control position of the table 4 as a movable part is input to the first module control system 10 . The first module control system 10 generates various first module instructions.

[0082] The first feedback control system 30 has a feedback loop including the first electric motor 2 . The first feedback control system 30 ...

no. 2 approach

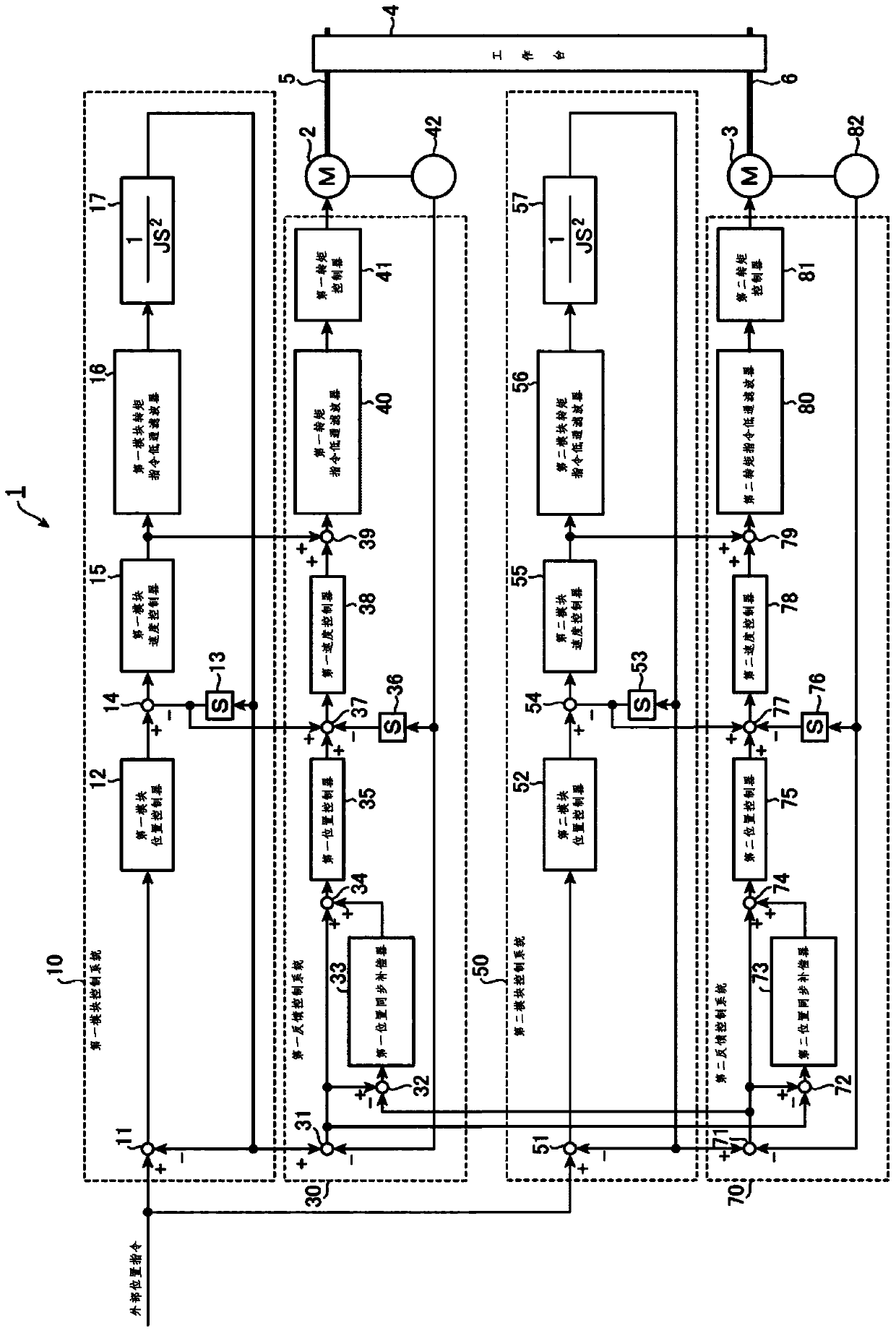

[0148] figure 2 It is a block diagram of a motor control device 1 according to a second embodiment of the present invention. figure 2 The motor control device 1 shown with figure 1 The difference between the shown device is that the second feedback control system 70 has a second synchronous position error obtainer 72 , a second position synchronous compensator 73 and a second synchronously compensated position error obtainer 74 .

[0149] The second synchronous position error obtainer 72, the second position synchronous compensator 73 and the second synchronous compensation position error obtainer 74 correspond to the first synchronous position error obtainer 32, the first position synchronous compensator 33 and the first synchronous compensation position Error acquirer 34.

[0150] Based on the second control position error acquired by the second control position error acquirer 71 and the first control position error acquired by the first control position error acquirer 3...

no. 3 approach

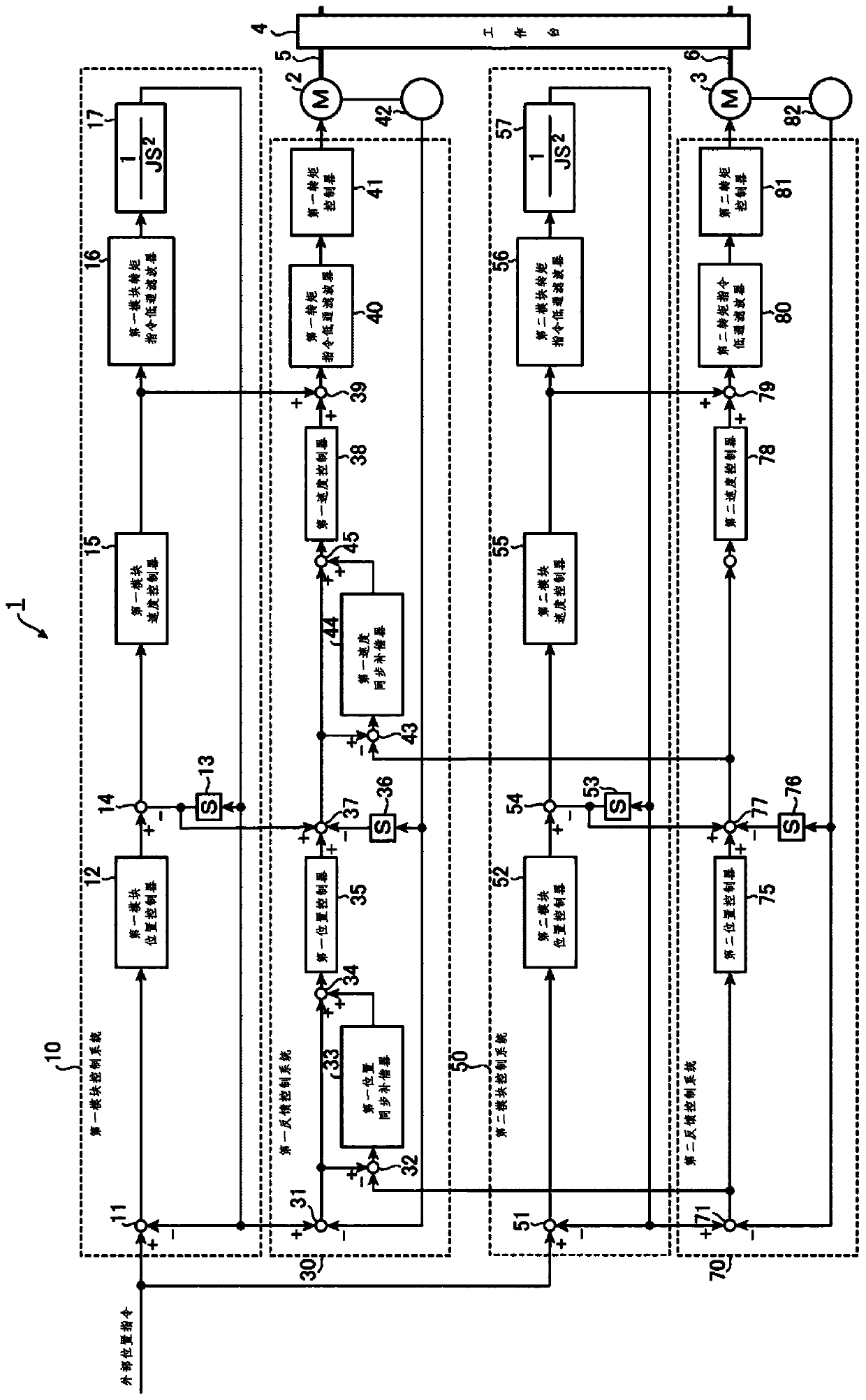

[0160] image 3 It is a block diagram of a motor control device 1 according to a third embodiment of the present invention. image 3 The motor control device 1 shown with figure 1 Compared with the shown device, the difference lies in that the first feedback control system 30 has: a first synchronous speed error obtainer 43 , a first speed synchronous compensator 44 and a first synchronous compensation speed error obtainer 45 .

[0161] Based on the first control speed error obtained by the first control speed error obtainer 37 and the second control speed error obtained by the second control speed error obtainer 77, the first synchronous speed error obtainer 43 obtains signals representing these control speed errors. The difference (synchronous speed error) is the first synchronous speed error. For example, the first synchronous speed error can be obtained by subtracting the other second control speed error from the first control speed error obtained by the first control sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com