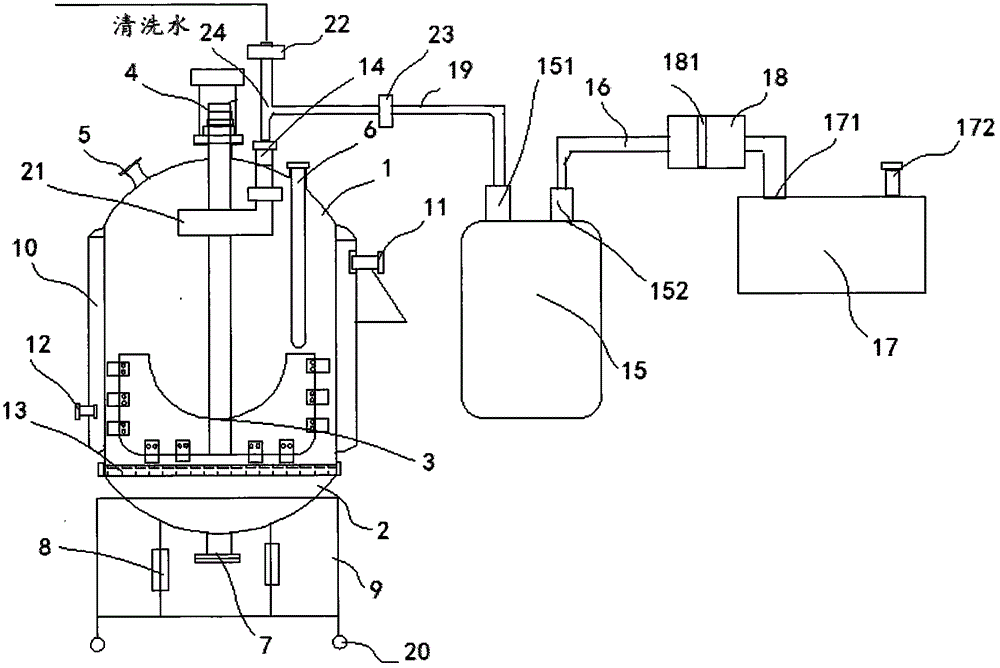

Water scrubbing vacuumizing evaporation filtering tank

A technology for vacuuming and filtering tanks, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve problems such as increasing production costs of enterprises, complex structure, and affecting workers' operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the substantial features and advantages of the present invention will be further described with reference to examples, but the present invention is not limited to the listed embodiments.

[0013] See figure 1 , a water washing and vacuuming evaporation filter tank, including a tank body 1, the tank body is fixed above by a bracket, the bottom of the tank body is provided with a detachable sealing connection bottom cover 2, and a stirring tank is installed in the tank 3, the stirrer is correspondingly connected to the drive device 4 through the stirring shaft, a thermometer is arranged in the tank, a heating jacket 10 using heat-conducting oil or hot water is arranged outside the tank, and a heat-conducting medium inlet 11 and an outlet are provided 12. The upper end of the tank body is provided with a liquid injection port 5 and a vacuum suction port 14, and a filter plate 13 is arranged on the upper end surface of the bottom cover 2, and a filter cloth is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com