Water-drop-shaped magnetic rod

A drop-shaped, magnetic rod technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem that the cylindrical magnetic rod cannot effectively control the material flow trajectory, cannot effectively control the material flow trajectory, and the cylindrical magnetic rod Small flow area and other problems, achieve good iron removal effect, improve iron removal effect, and improve iron removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] refer to Figure 6 Shown, a kind of water-drop type magnet bar comprises water-drop type monolithic magnetic core, and described magnetic core comprises magnetic material piece 2 and magnetic pole piece 1, and described magnetic material piece and described magnetic pole piece pass core bar 3 and nut 4 ( or other means) fixed as a whole.

Embodiment 2

[0033] refer to Figure 7 As shown, a droplet-shaped magnetic bar includes a droplet-shaped integral magnetic core, and the magnetic core includes a magnetic material block 2 and a magnetic pole piece 1, and the magnetic material block 2 and the magnetic pole piece 1 pass through a core rod 3 and a nut 4 (or other methods) fixed together, the outside of the magnetic core is provided with a stainless steel tube 5 with a drop-shaped cross-section, the stainless steel tube 5 is a sleeve, and one end of the stainless steel tube 5 is welded or bonded with a drop-shaped end plug , the other end is open, during normal operation, the magnetic core is plugged in the casing, the outside of the casing is in contact with the material, the magnetic pollutants in the material are adsorbed outside the casing, and the magnetic core is pulled out of the casing when it is necessary to unload the iron , the magnetic pollutants adsorbed on the outside of the bushing will fall off naturally due to...

Embodiment 3

[0035] refer to Figure 8 As shown, a droplet-shaped magnetic bar includes a droplet-shaped integral magnetic core, and the magnetic core includes a magnetic material block 2 and a magnetic pole piece 1, and the magnetic material block 2 and the magnetic pole piece 1 pass through a core rod 3 and a nut 4 (or in other ways) fixed together, the outside of the magnetic core is wrapped with a stainless steel tube 5 with a drop-shaped cross-section, and the two ends of the stainless steel tube 5 are formed by welding or adhesively sealing with a water-drop-shaped end plug.

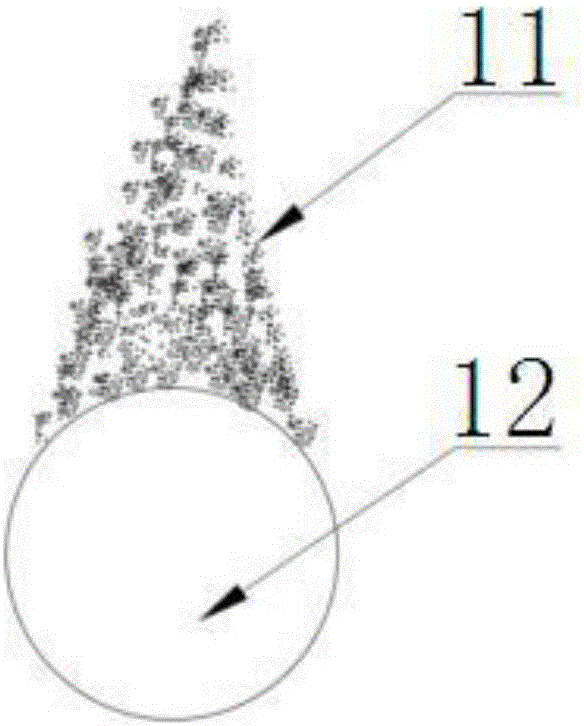

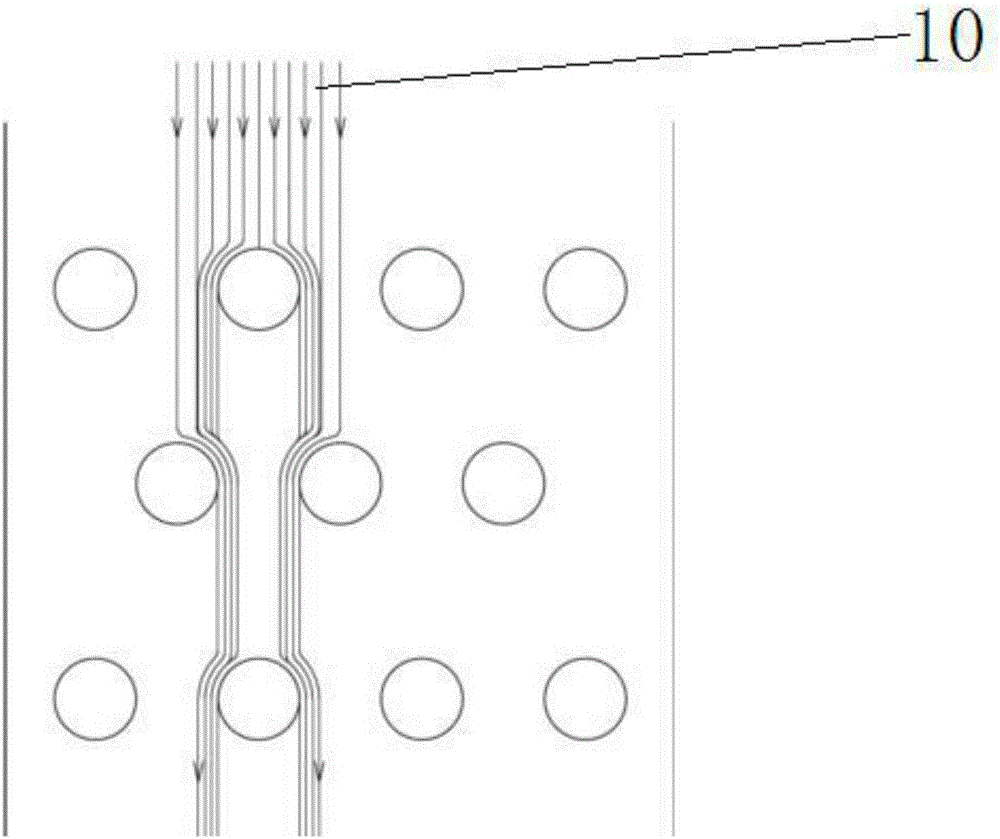

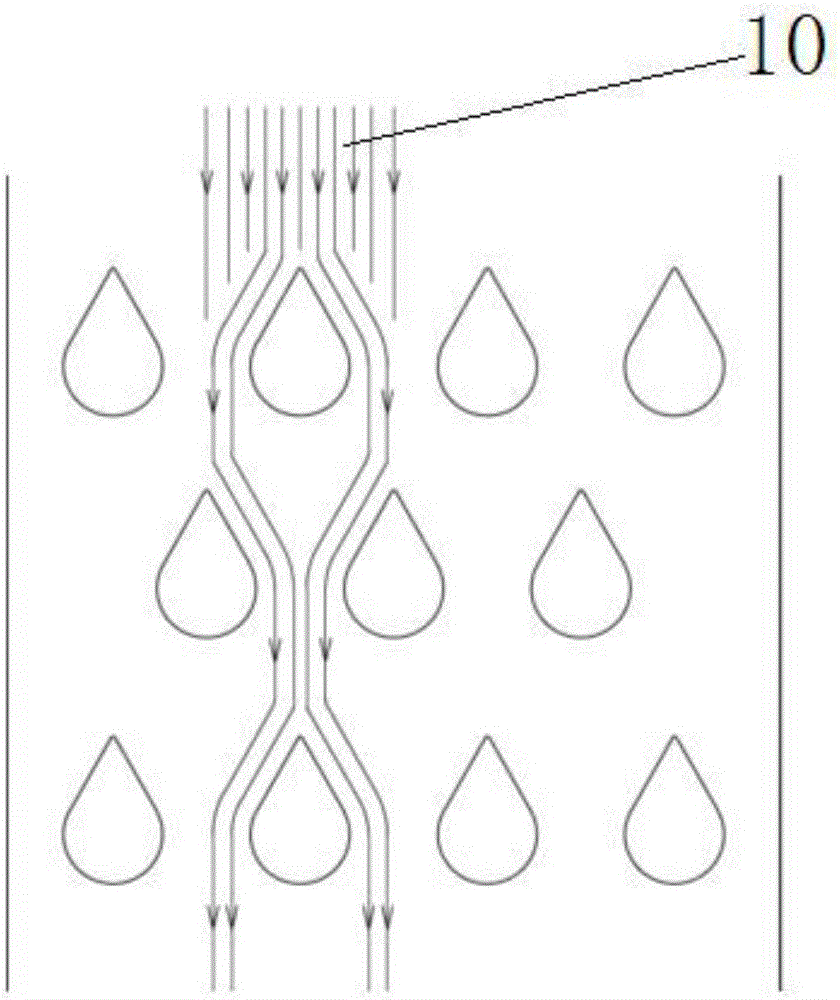

[0036] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention changes the traditional circular magnetic bar into a water drop-shaped magnetic bar. When the material 11 falls from above, the material 11 fully contacts the upstream surface 6 of the water-drop-shaped magnetic bar, and the upstream surface 6 of the water-drop-shaped magnetic bar is larger than On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com