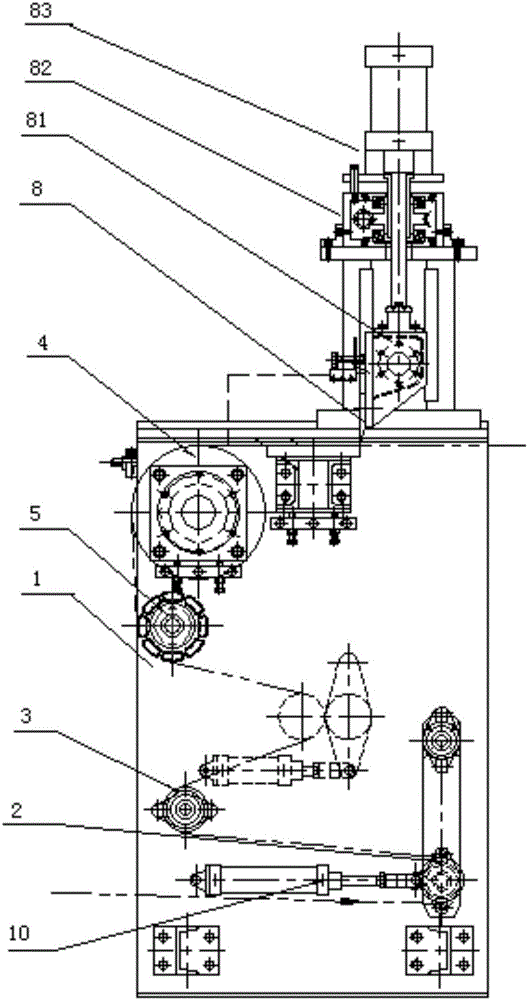

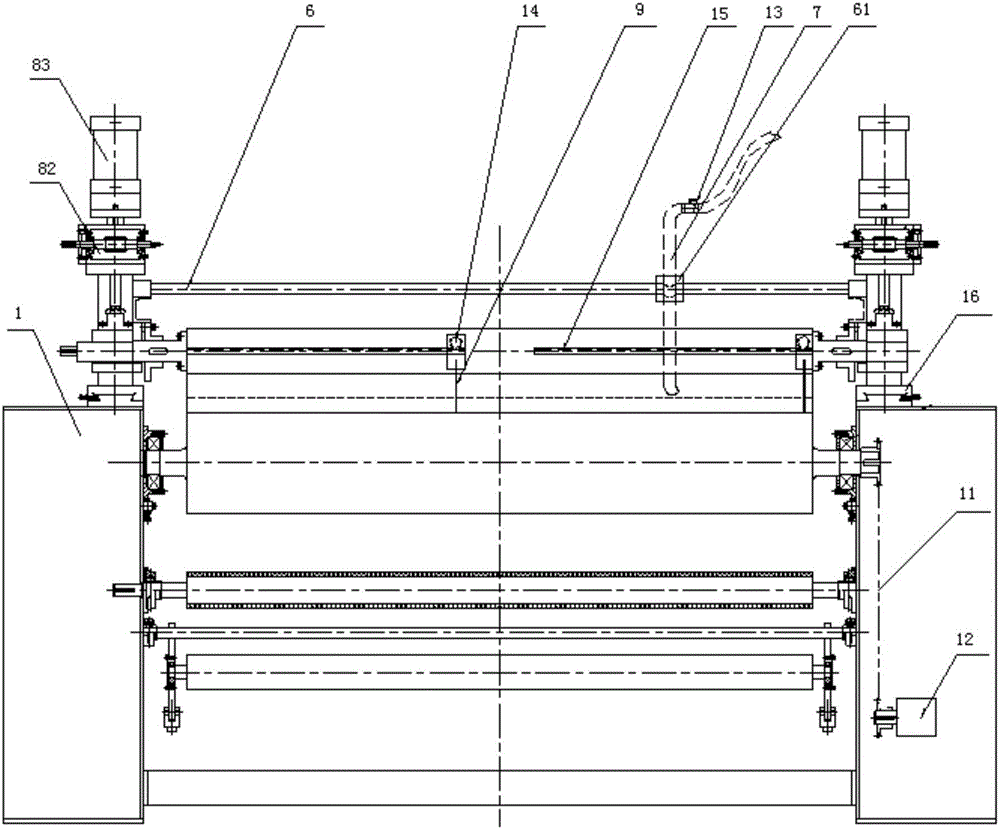

Automatic gluing machine

A gluing machine, automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low automation, high processing cost, and many people, so as to reduce labor, low transformation cost, and gluing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

[0032] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0033] In the description of the present invention, it should be noted that the orientations or positional relationships indicated by the terms "inner", "outer", "left", "right" etc. are based on the orientation or positional relationship in the working state of the present invention, and are only In order to facilitate the description of the present invention and simplify the description, it does not indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com