Oil-gas lubrication mechanism for numerically controlled machine tool

A technology of oil-air lubrication and CNC machine tools, which is applied in the direction of engine lubrication, lubricating parts, engines, etc., can solve problems such as poor lubrication effect, inconvenient use, and inconvenient control, and achieve good application prospects, easy control, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

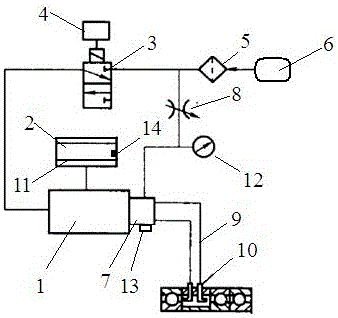

[0016] Such as figure 1 As shown, the oil-air lubrication mechanism for CNC machine tools of the present invention includes an oil injector 1, the oil inlet end of the oil injector 1 communicates with the lubricating oil tank 2, and the bottom of the lubricating oil tank 2 is provided with a filter screen 11, which can filter the lubricating oil Impurities in the oil tank 2 ensure the reliability of the lubricating oil and prevent blockage of plastic pipes. An oil level sensor 14 is arranged in the lubricating oil tank 2 to add lubricating oil when the oil quantity is insufficient. The valves 3 communicate with each other, the air valve 3 is connected with a timer 4, the air valve 3 is connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap