Method for peeling off laminate film and method for manufacturing functional film

A manufacturing method and functional technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as functional film damage, and achieve the effect of inhibiting damage

Inactive Publication Date: 2016-08-24

FUJIFILM CORP

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] However, it has been found that the functional film may be damaged by the peeling method, which is generally considered not to cause damage such as wrinkles and scratches to the functional film.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0081] Hereinafter, an Example is given and this invention is demonstrated further concretely. Materials, production conditions, and the like shown in the following examples can be appropriately changed without departing from the gist of the present invention. Therefore, the scope of the present invention is not limited to the following specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

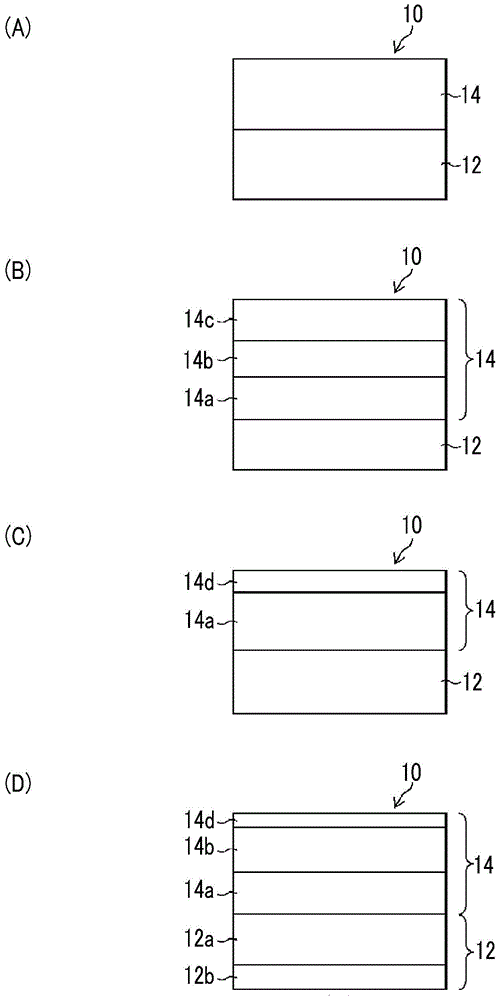

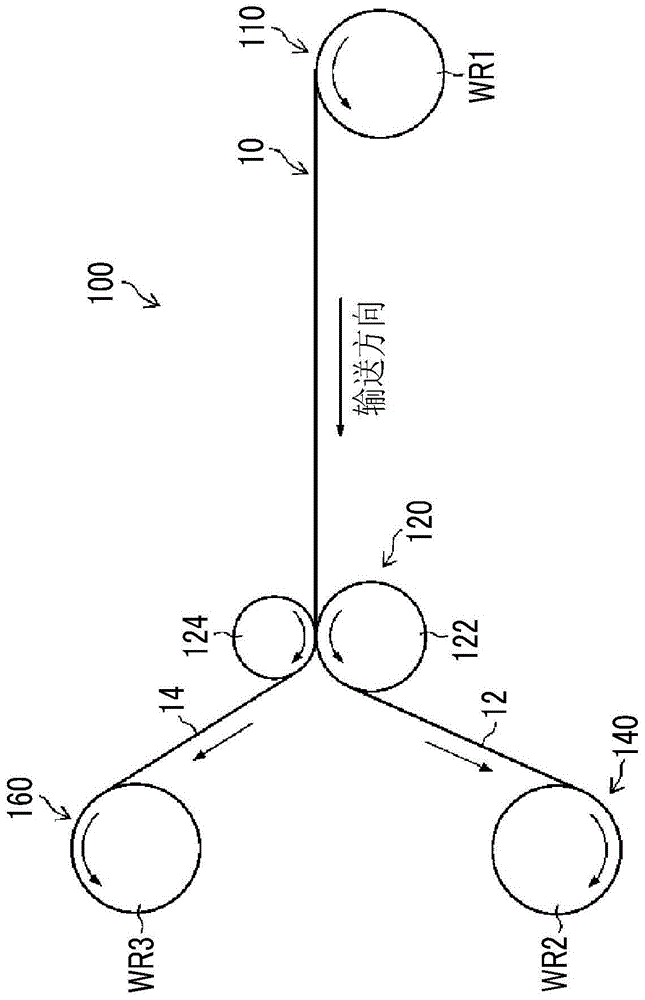

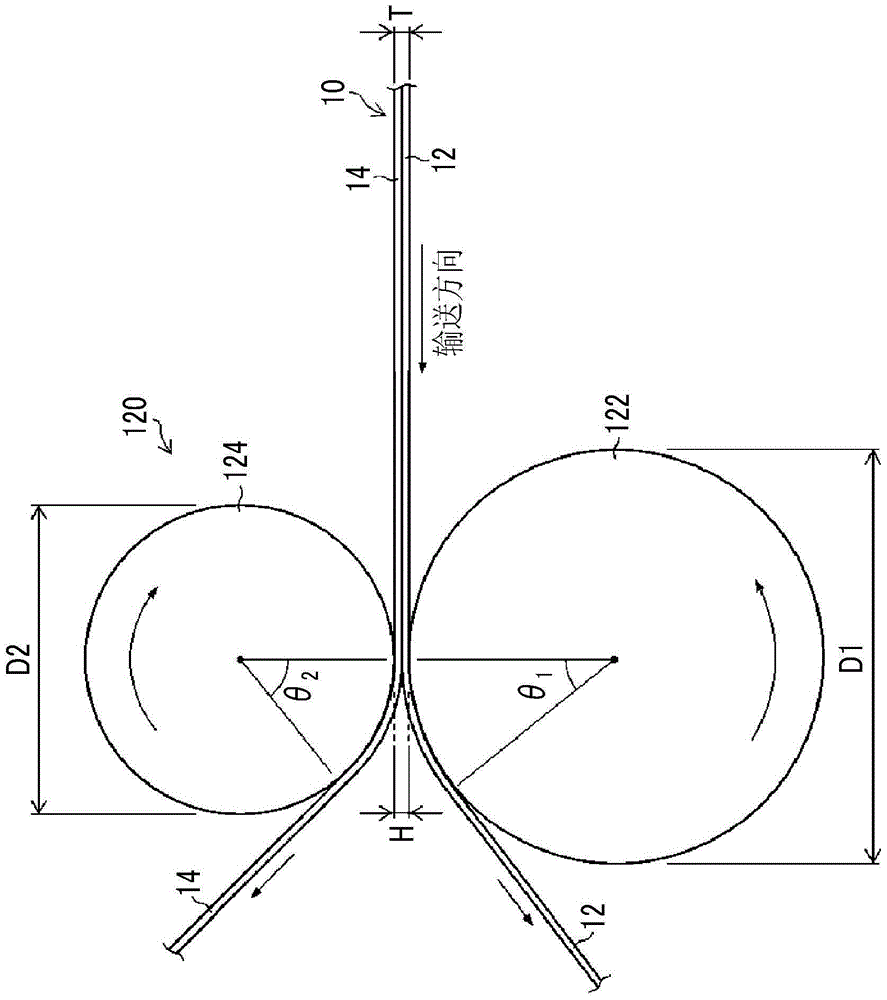

The invention provides a method for peeling off a laminate film and capable of preventing damage to a functional film, and a method for manufacturing the functional film. The method for peeling off the laminate film, according to the invention, includes a step of transporting a laminate film (10) having a base film (12) and a functional film (14) laminated on the base film (12); and a peeling step, in which, through a first roller (122) and a second roller (124) having a smaller diameter than that of the first roller (122), the base film (12) and the functional film (14) are peeled from each other, by sandwiching the laminate film (10) to be transported from one side of the base film (12) by the first roller (122) and from one side of the functional film (14) by the second roller (124), and winding the functional film (14) around the second roller (124) and the laminate film (12) around the first roller (122).

Description

technical field [0001] The present invention relates to a method for peeling off a laminated film and a method for manufacturing a functional film. Background technique [0002] Conventionally, there is known a method of peeling off an unnecessary part of the film from a laminated film in which a plurality of films are laminated to obtain a film (functional film) as a product. For example, Patent Document 1 discloses that the sheet on which the base film and the release film are laminated is run, and the release sheet is slid while being in contact with a squeegee of a plate-shaped member to perform peeling. [0003] Furthermore, Patent Document 2 discloses a method of peeling a protective film from a photosensitive web which is a laminated film composed of a plurality of layers. In this method, a photosensitive web is sandwiched between a suction roller and a peeling roller, and the base film including the photosensitive resin layer is sucked and conveyed using the suction...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B38/10B32B23/08B32B23/20B32B27/06B32B27/08B32B27/30B32B27/32B32B27/36

CPCB32B23/08B32B23/20B32B27/06B32B27/08B32B27/306B32B27/32B32B27/36B32B38/10B32B2323/04B32B2323/10B32B2329/04

Inventor 大场孝浩楠本将之

Owner FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com