Self-check method for control part of water purifier

A technology of control components and water purifiers, applied in the direction of electrical testing/monitoring, osmosis/dialysis water/sewage treatment, etc., can solve the problem of increasing expenses, remote users are difficult to get timely and good services, and the penetration rate is less than 3% and other problems to achieve the effect of simplifying the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

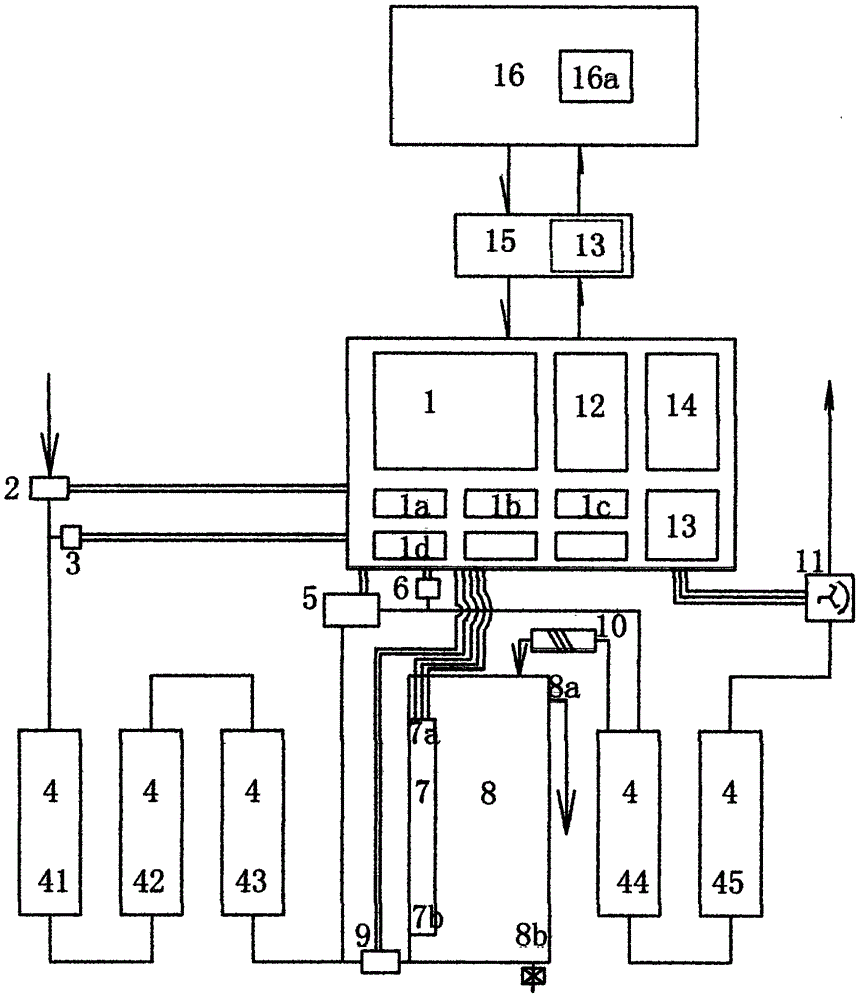

[0023] Example 1. In the drawings, the electric control device in the running mode is switched to the self-test mode by the switch key 1a. At this moment, the water purifier is in the standby detection state of abnormal operation, and only the selected detection control components are in the operational state. All the control components and related linkage items can be automatically selected and detected sequentially, or the corresponding control components to be detected can be selected by using the selection key 1b, and the relevant detection items can also be directly selected according to the fault phenomenon.

[0024] Firstly, test the electronic control device in the self-test mode. For the circuit mode in which a control switch or relay is set in the branch output circuit of the electronic control device, and the control component is connected to form a loop and control the latter to be turned on or off, the output indicator is connected to the electric control device....

Embodiment 2

[0039] Example 2. On the basis of Embodiment 1, the electric control valve is set in the water passing channel together with at least one of the control components of the water pressure touch switch or the flow sensor or the water level control switch, and the corresponding control components are set at the same time In the self-inspection mode linked with the electric control valve, the display and control device will prompt the status of the control parts accordingly. Among them, for the self-inspection mode in conjunction with the electric control valve and the water pressure touch switch, the electric control valve will be given separately when the electric control valve is turned on or off. The display and control device correspondingly prompts different content corresponding Two states associated with the electric control valve and the water pressure touch switch; for the self-inspection mode of the electric control valve and the flow sensor linkage, the impeller of the ...

Embodiment 3

[0044]Example 3. On the basis of Embodiment 1 and 2, an electric control valve 2, a booster pump 5, a return water tank 8 and a built-in high and low water level dual water level combination control switch 7 are set in the front water passage; In the self-test mode, select the booster pump to be linked with the electric control valve, the return water electric control valve and the high and low water level control switch of the return water tank: start the electric control valve and the booster pump to run, and simulate the water flowing through the previous water channel. The water inlet of the three water outlet filter gallbladder. The concentration discharge port enters the return water tank; when the water level of the return water tank rises and triggers the action of the high water level control switch, or after the booster pump has been operating normally for a specified time, close the electronically controlled valve 2 in the previous water passage and start the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com