High-strength corrosion-resistant spring steel and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the field of spring steel and its manufacturing, can solve the problems of easy fracture and affecting vehicle safety, etc., achieve long corrosion fatigue life, decrease corrosion rate and corrosion pit depth, and good corrosion resistance and the effect of fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A12 and comparative example B1-B3

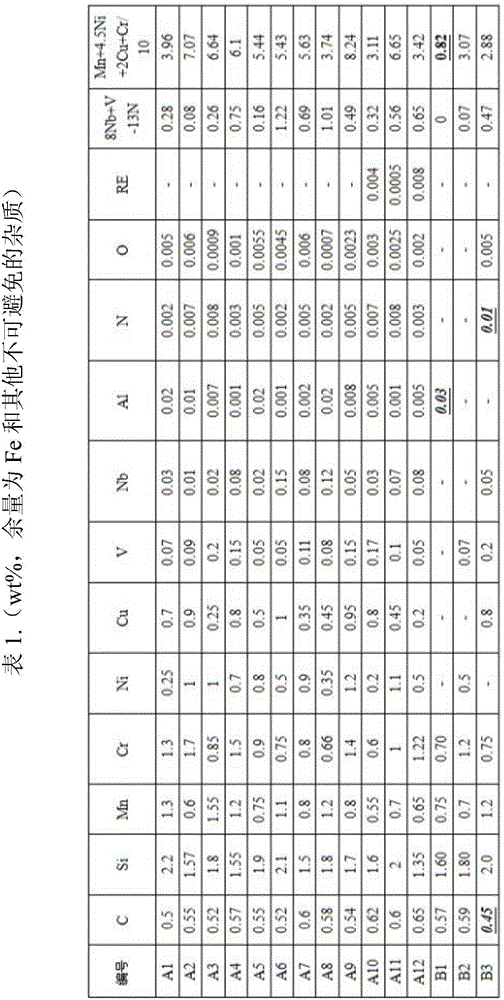

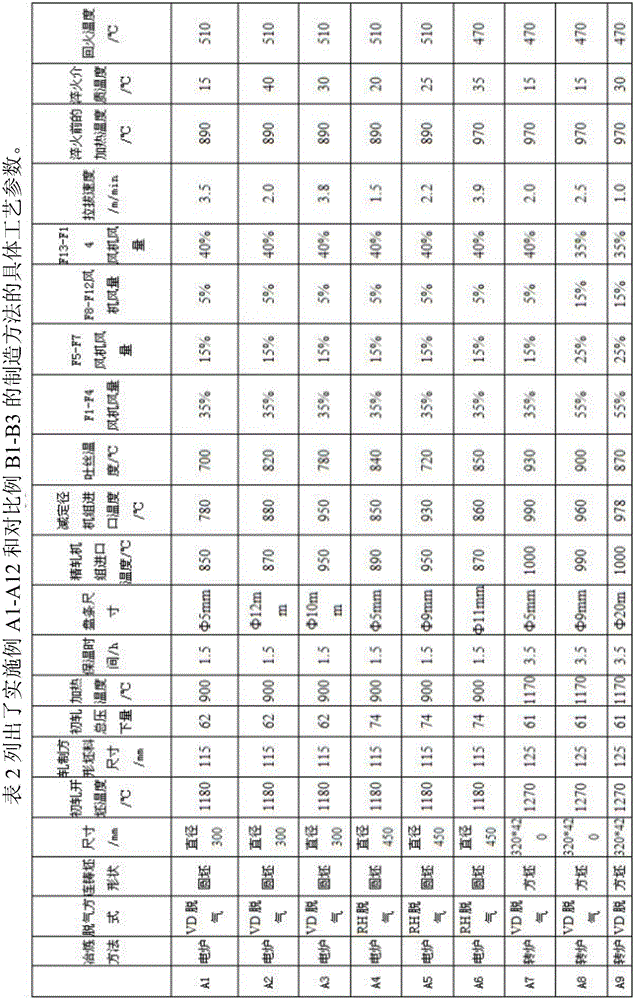

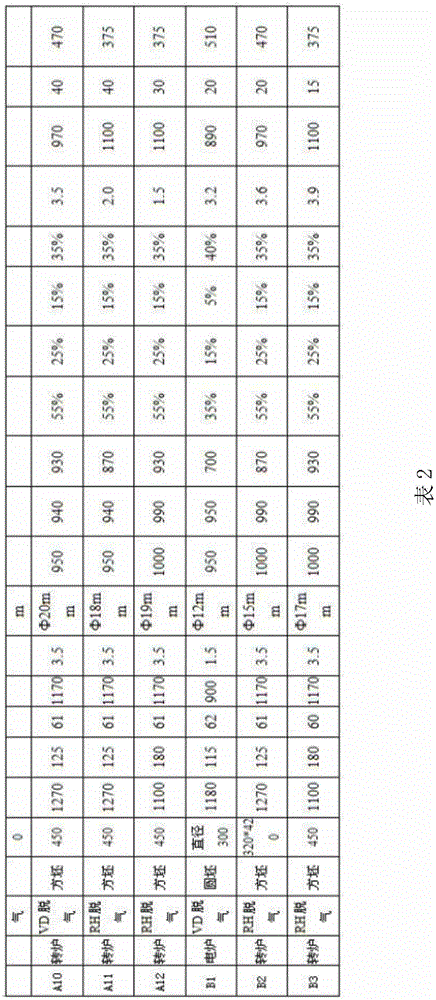

[0068] The high-strength corrosion-resistant spring steel in the above-mentioned embodiments and comparative examples adopts the following steps to make (the specific process parameters of each embodiment and comparative examples are referring to Table 2):

[0069] (1) smelting and refining, control the mass percentage distribution of the chemical elements of Examples A1-A12 and Comparative Examples B1-B3 as shown in Table 1;

[0070] (2) Continuous casting;

[0071] (3) Bloom rolling;

[0072] (4) heating;

[0073] (5) Finish rolling;

[0074] (6) Stelmore cooling after rolling, the wire rod structure is sorbite plus a very small amount of ferrite after Stelmore cooling;

[0075] (7) wire rod drawing;

[0076] (8) Heat treatment: quenching + tempering, wherein the heating temperature before quenching is 890-1100°C, the temperature of the quenching medium is 15-40°C, and the tempering temperature is 375-510°C.

[0077]

[0078]

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com