Low-resilience and high-formability high-strength steel and manufacturing method thereof

A manufacturing method and formability technology, applied in the direction of manufacturing converters, etc., can solve the problems of high springback and high production process requirements, and achieve the effects of improving strength, comprehensive mechanical properties, and good market application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

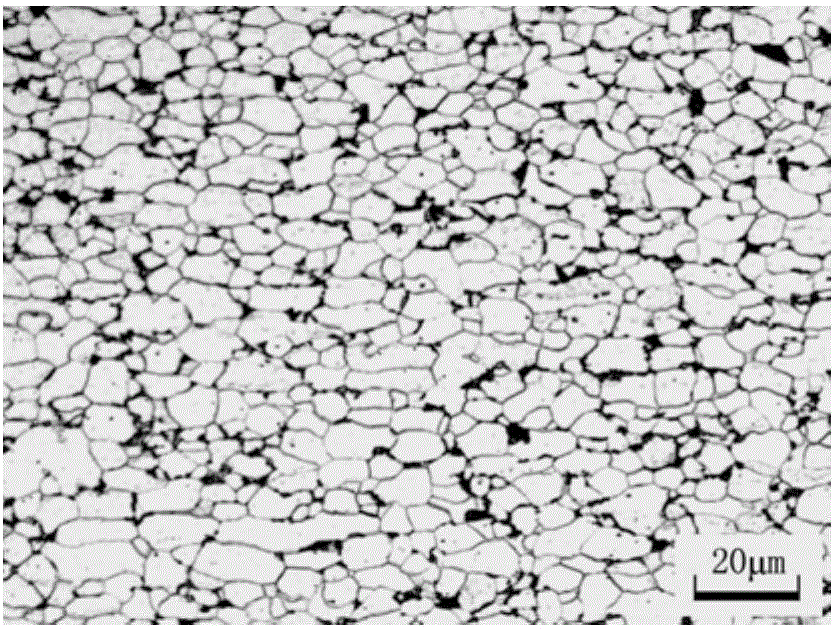

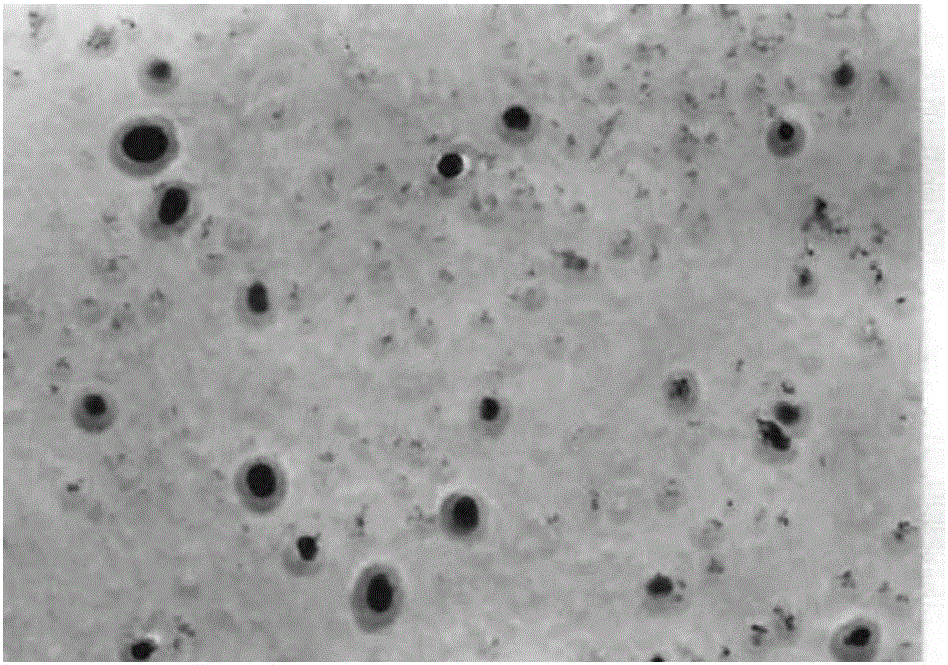

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

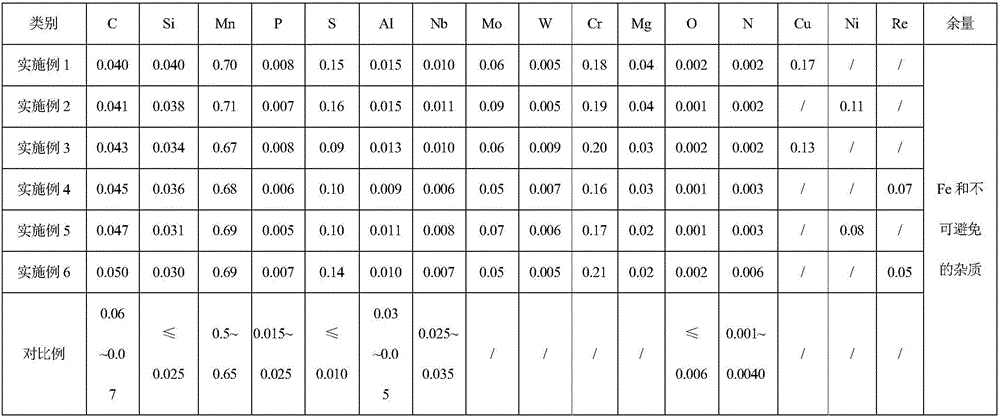

[0043] Chemical composition design:

[0044] The chemical composition and weight percentage in the high-strength steel with low springback and high formability of Examples 1 to 6 and the comparative steel are shown in Table 1;

[0045] The manufacturing method of the high-strength steel with low resilience and high formability of embodiments 1 to 6 is as follows:

[0046] 1) Converter steelmaking: set the target temperature of tapping to 1650°C;

[0047] 2) Argon blowing: the treatment time of argon blowing is controlled within 5-10 minutes;

[0048] 3) Continuous casting: protective pouring measures are adopted during continuous casting. The long nozzles of the large and medium ladles are protected by argon seals for pouring, and the steel flow channels of the tundish are sealed with argon. Magnesium materials and alkaline tundish powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap