Arch hexagonal steel box beam manufacturing method

A production method and hexagonal technology, which are applied in the directions of bridges, bridge materials, bridge construction, etc., can solve the problems of not having the mature technology for making arched hexagonal steel box girder, and achieve lower construction cost, convenient operation, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

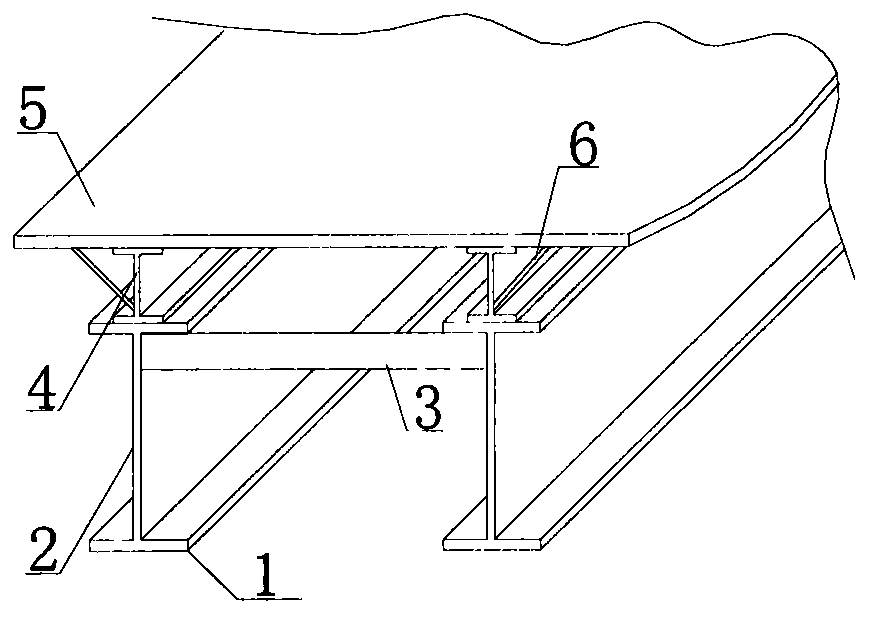

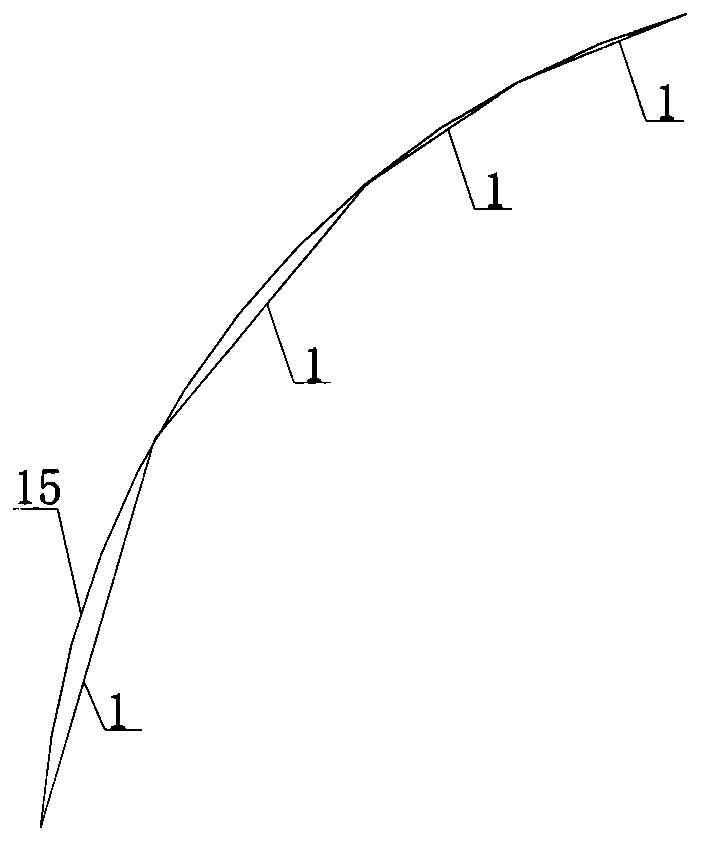

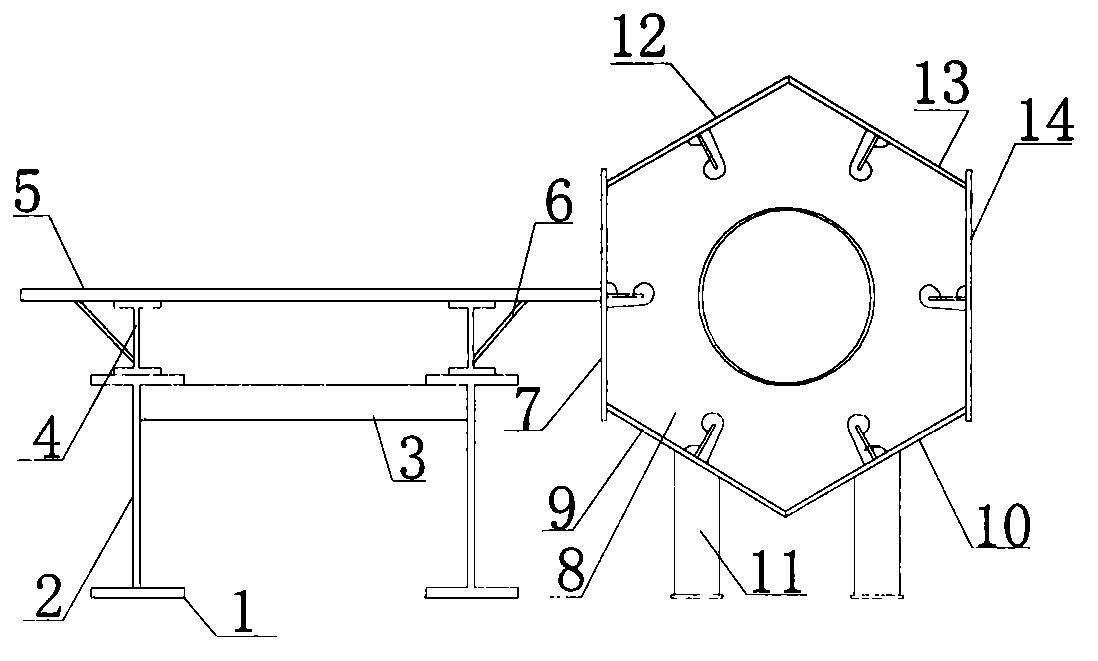

[0009] Embodiment one: see figure 1 , figure 2 , image 3 , the present invention relates to a method for manufacturing an arched hexagonal steel box girder. Firstly, the mold used for the arched hexagonal steel box girder is manufactured. The mold includes a base 1 and a template 5, and is characterized in that: The base 1 includes a bottom beam 2, a joist 4, a connecting plate 3, and a strut 6. The bottom beam 2 is processed by two No. 56 I-beams, and the horizontal distance between the two No. 56 I-beams is 300 mm. The length of the bottom beam 2 is square, and the connecting plate 3 is used to connect two No. 56 I-beams every 500 mm. The joist 4 is processed by two No. 32 I-beams. The joist 4 is placed on the bottom The middle position of the upper plane of the beam 2 is connected with the bottom beam 2 as a whole. The template 5 is processed by 16 mm thick steel plate, and one side of the template 5 is processed into an arc, which is the same as the arc of the lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com