Suspension bridge superstructure demolition and replacement installation method

An installation method and suspension bridge technology, applied in suspension bridges, bridges, bridge maintenance, etc., can solve the problems of unstable, slow, and hidden safety hazards of catwalks, and achieve the effect of small damage to the main cable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0027] Such as figure 1 As shown, the present invention is a suspension bridge superstructure removal and replacement installation method,

[0028] The specific implementation steps are as follows:

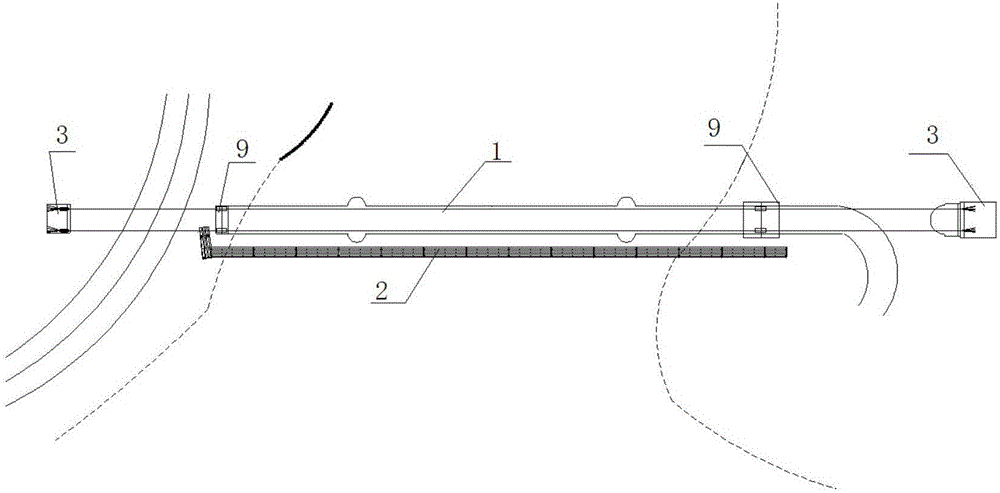

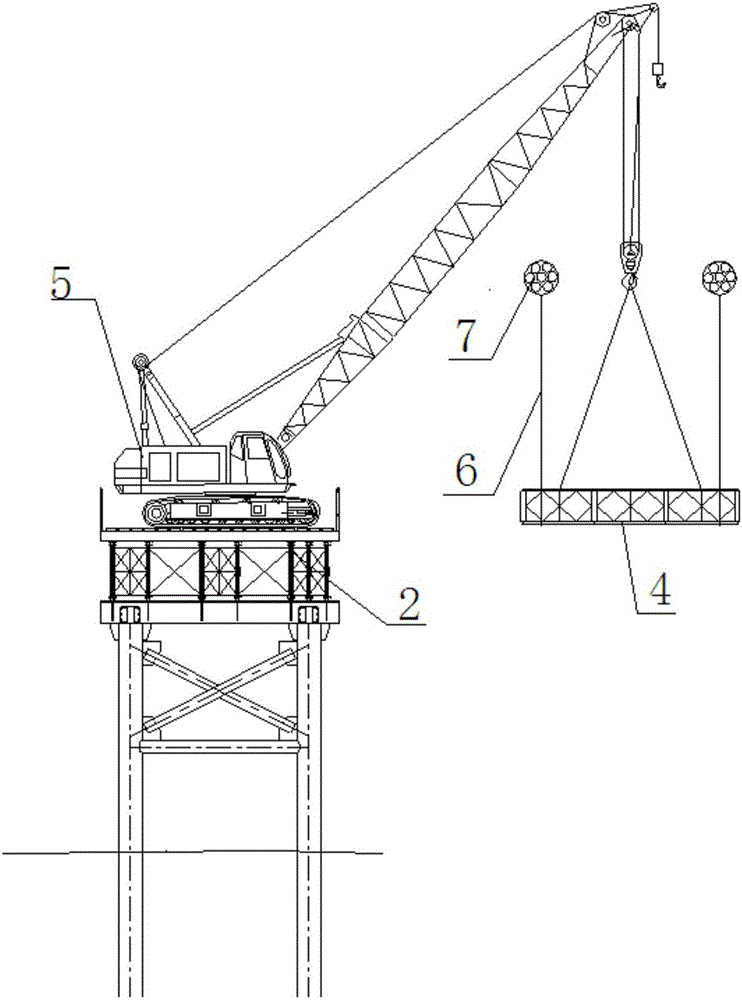

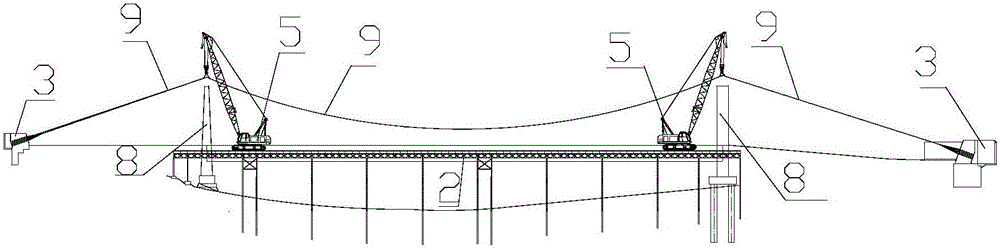

[0029] step one:. A trestle 2 is set up at a position 2m to 3m away from the outer side of the suspension bridge 1 . The trestle is parallel to the suspension bridge 1 and is used for the temporary passage of pedestrians and vehicles and the trestle 2 for hoisting and transporting platforms. The trestle 2 is connected to the roads (approach bridges) at both ends of the suspension bridge 1; the end of the trestle is bent toward the suspension bridge and fixed on one side of the cable tower of the suspension bridge to ensure the stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com