Hydraulic buffer device and buffer oil cylinder comprising device

一种液压缓冲、油缸的技术,应用在液压零部件领域,能够解决缓冲质量不够好、零部件缓冲效果影响较大、无法调节等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

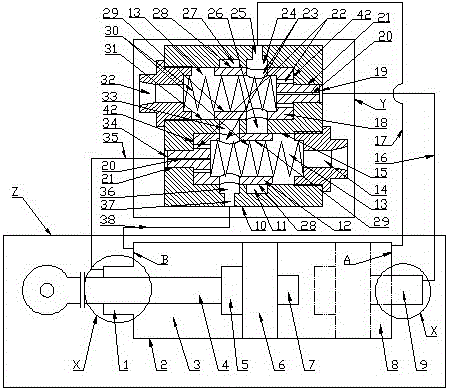

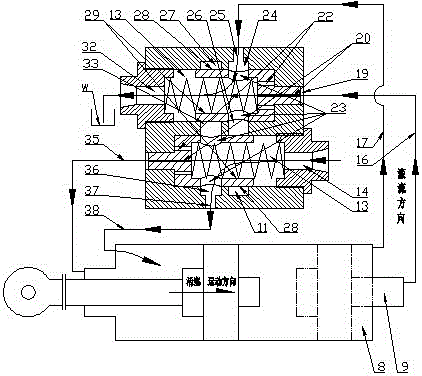

[0097] A buffer cylinder, such as Figure 35-43 As shown, it includes earrings 52, lock pins 53, cylinder head B, cylinder head seat C, cylinder body 2, piston rod 4, piston 6 and cylinder bottom A. It is characterized in that: the buffer cylinder also includes the principle Figure 1-4 The hydraulic shock absorber shown. The buffer device includes an annunciator X and a buffer valve Y, the annunciator X is composed of a signal cavity and a signal plug, and the buffer valve Y is composed of a valve body, a slide valve and a buffer elastic. In order to facilitate understanding and comparison, this embodiment ( Figure 35-43 ) follows the principle Figure 1-4 The part number, the specific structure is detailed as follows.

[0098] The cylinder head C is a ring with a positioning cavity 59 in the center, and the positioning concave hole 60 is coaxially arranged at one end of the positioning cavity 59, and one end of the cylinder body 2 is inserted into the positioning concave h...

Embodiment 2

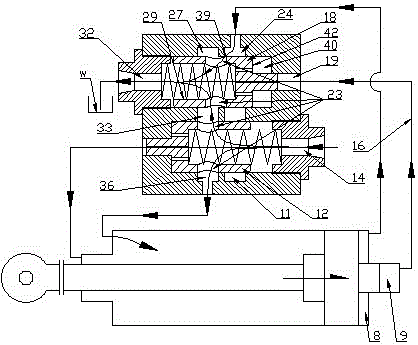

[0110] A buffer cylinder, such as Figure 44-47 As shown, it includes an earring 52, a lock pin 53, a cylinder head B, a cylinder head seat C, a cylinder body 2, a piston rod 4, a piston 6 and a cylinder bottom A. It is characterized in that: the buffer oil cylinder also includes the principle Figure 16-17 The two-way hydraulic shock absorber shown. The buffer device includes an annunciator X and a buffer valve Y, the annunciator X is composed of a signal cavity and a signal plug, and the buffer valve Y is composed of a valve body, a slide valve and a buffer elastic. In order to facilitate understanding and comparison, this embodiment follows the principle Figure 16-17 Compared with Example 1, only the structure of the buffer valve Y has changed, and now only the changed parts are described in detail below, and the rest refer to the foregoing.

[0111] Shock valve Y is equipped with two sets of slide valves, using two spools II12b (see the principle for the specific struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com