Aluminum-based composite foam material filling pipe whip limiting part

A technology of aluminum-based composite foam and filling pipes, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of large impact force and deformation, achieve good rigidity, increase contact area, and good The effect of cushioning energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

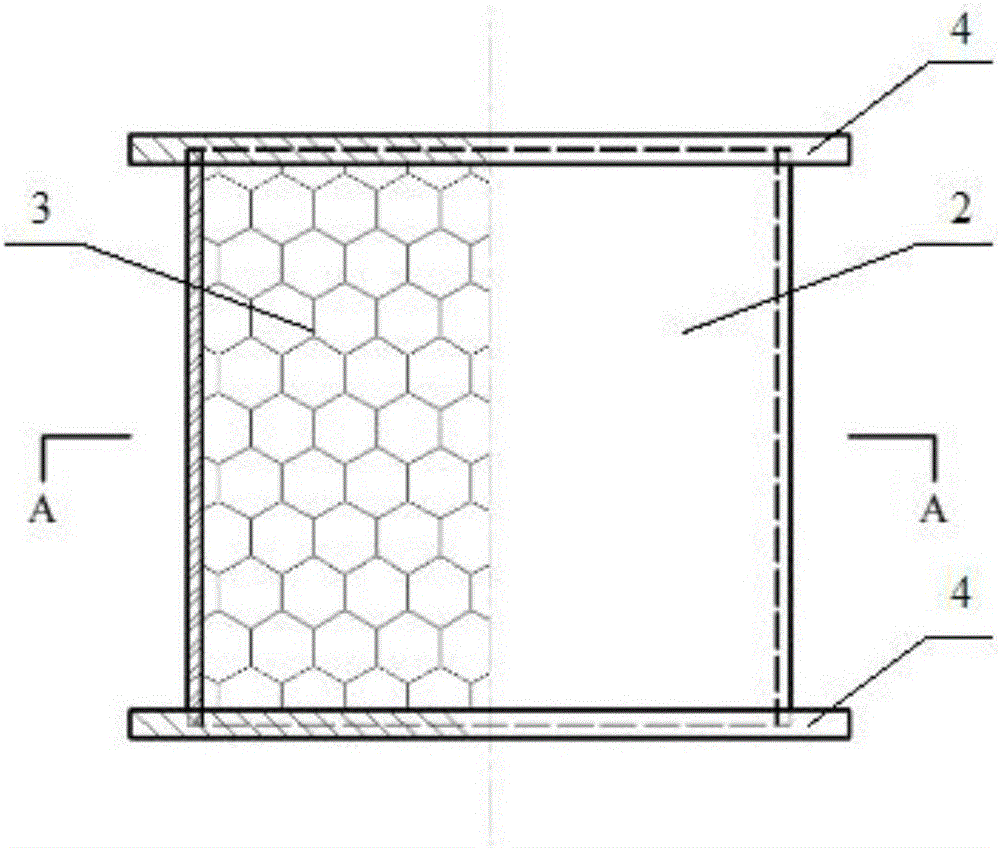

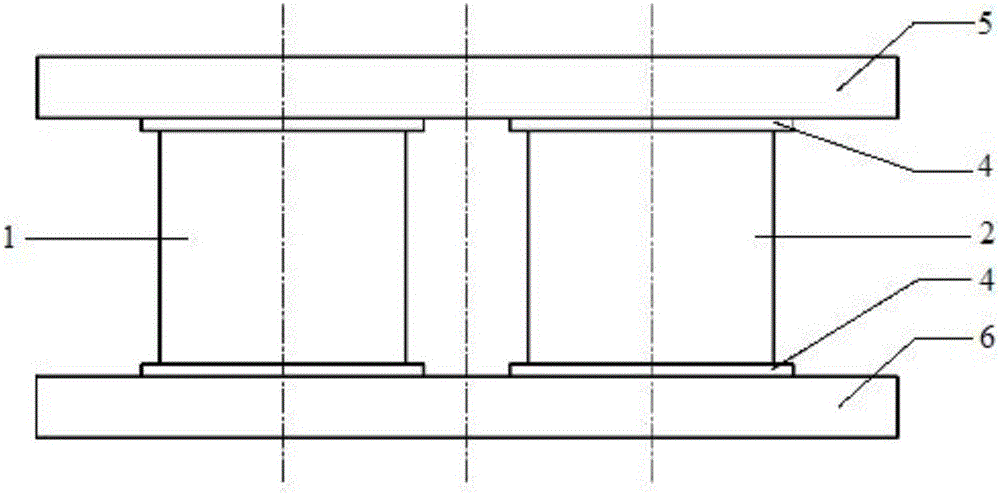

[0021] Specific embodiment 1: An aluminum-based composite foam material filled tube slam limiter in this embodiment is composed of a plurality of aluminum-based composite foam material filled tubes 1, upper connecting steel plates 5 and lower connecting steel plates 6;

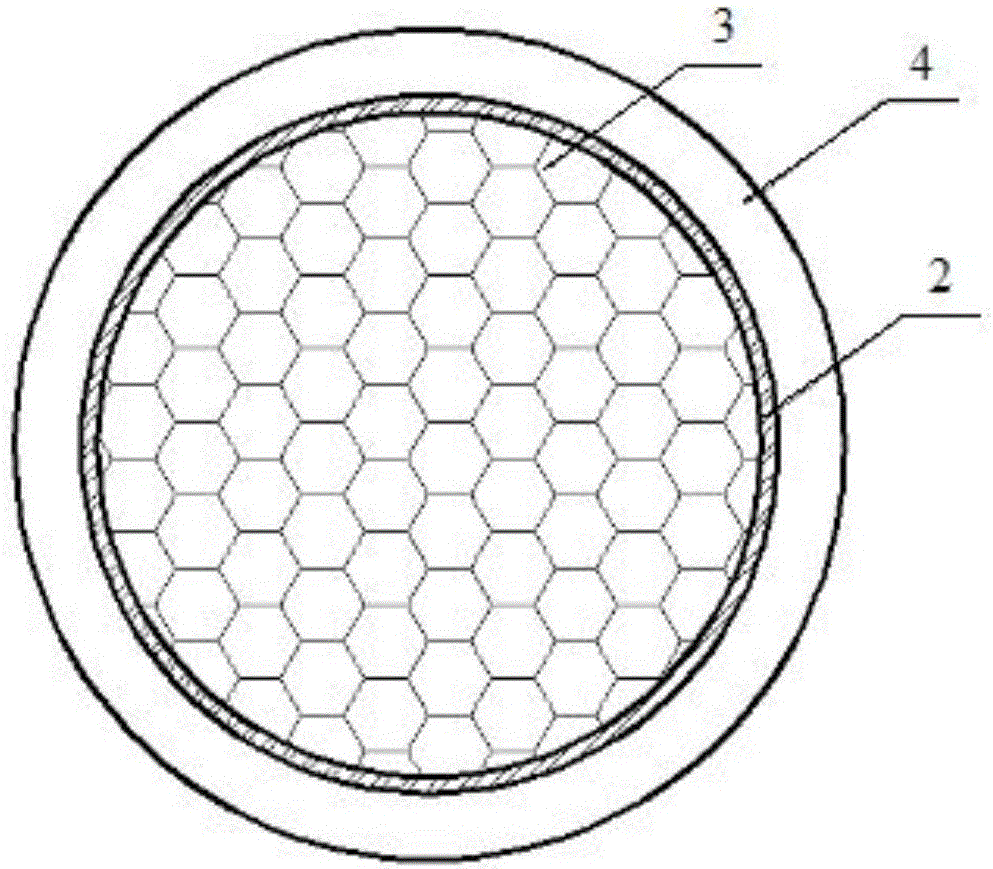

[0022] The aluminum-based composite foam material filling tube 1 is composed of a stainless steel tube 2, an aluminum-based composite foam material 3 filled with the stainless steel tube 2, and a circular fixed steel plate 4 with grooves covering both ends of the stainless steel tube 2;

[0023] The multiple aluminum-based composite foam material filling tubes 1 are arranged in a rectangular array a×b; wherein 1≤a≤3, and a is an integer, 1≤b≤3, and b is an integer;

[0024] The two ends of the stainless steel pipe 2 are embedded in the groove of the circular fixed steel plate 4 and fixed by welding;

[0025] The fixed steel plate 4 at the upper end of the aluminum-based composite foam material filling tube 1 i...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that: the stainless steel pipe 2 is an AISI304 stainless steel pipe. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the density of the aluminum-based composite foam material 3 is 1385kg / m 3 . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com