Multi-shell-side shell-and-tube heat exchanger

A shell-and-tube heat exchanger and multi-shell pass technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of increasing equipment use space, large temperature difference between refrigerant inlet and outlet, and heat transfer problems. The problem of increasing the size of the device can be solved, and the effect of reducing the workload can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

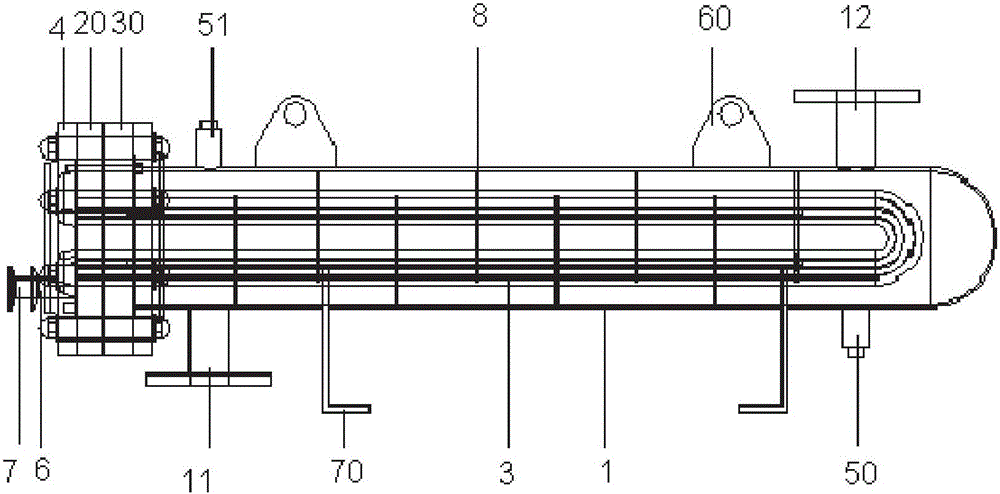

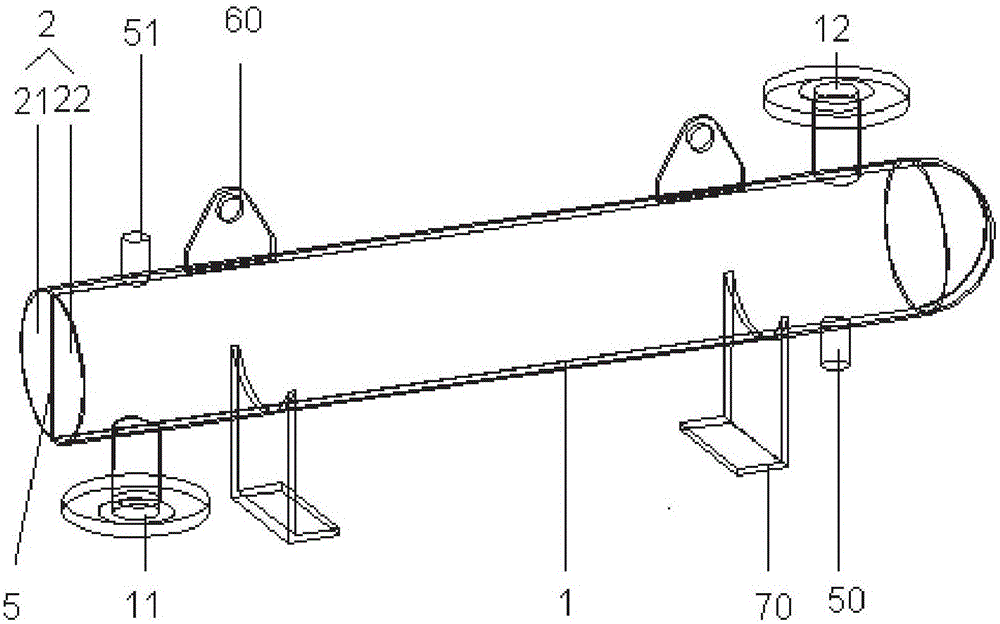

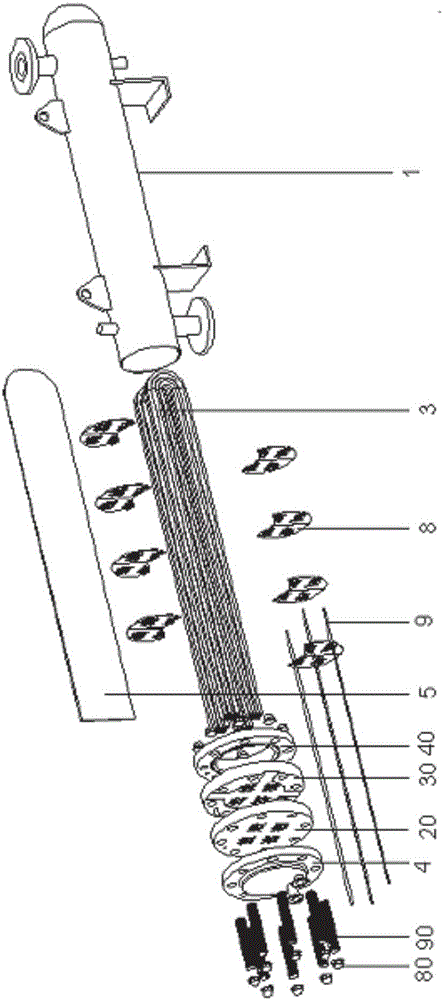

[0029] Embodiment one: if Figures 1 to 5 As shown, the present invention provides a multi-shell-side shell-and-tube heat exchanger, which belongs to the field of fluid temperature control and can be used to cool heat medium. The embodiment will be further described in detail below with reference to the accompanying drawings.

[0030] like Figures 1 to 3 As shown, the multi-shell-side shell-and-tube heat exchanger provided in this embodiment includes a shell side 1, and a housing cavity 2 is arranged in the shell side 1, and a heat transfer tube bundle 3 is accommodated in the housing cavity 2, and one end of the shell side 1 is provided with There is a flat cover head 4. Wherein, the housing chamber 2 of the shell side 1 is provided with an isolation plate 5, and the isolation plate 5 is fixed on the inner surface of the accommodation chamber 2 by a fixing block (not shown in the figure). There can be one, two or more isolation plates 5, and the isolation plates 5 equally ...

Embodiment 2

[0045] Embodiment 2: The present invention provides a multi-shell-side shell-and-tube heat exchanger, which is basically the same in structure as the shell-and-tube heat exchanger described in Embodiment 1, except that two isolation plates are arranged in the storage cavity, and the isolation plates will The accommodation cavity is divided into a first cavity, a second cavity and a third cavity, and the heat transfer tube bundle includes a primary tube bundle located in the first cavity, a secondary tube bundle located in the second cavity, and a three-stage tube bundle located in the third cavity. The first-stage tube bundle, the first-stage tube bundle, the second-stage tube bundle, and the triode tube bundle are connected back and forth; the medium in the first-stage tube bundle passes through the refrigerant in the first cavity for primary heat exchange, and then enters the second-stage tube bundle for secondary heat exchange in the second cavity. The heat exchange will fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com