Quantum dot film product and producing method thereof

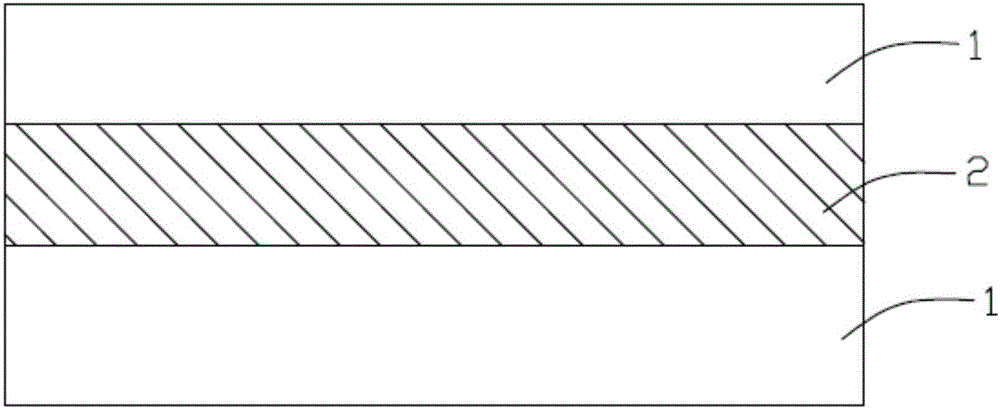

A technology of quantum dot film and production method, which is applied in the field of conductive film, can solve problems such as uneven luminescence, uneven pressure, and difficult control of the thickness of quantum dot layer 2, and achieve the effects of improving adhesion, preventing infiltration, and increasing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

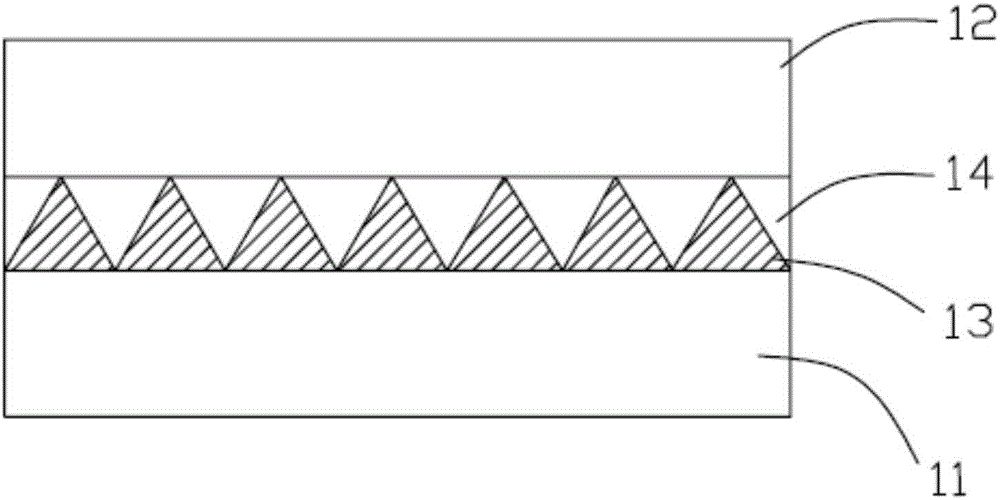

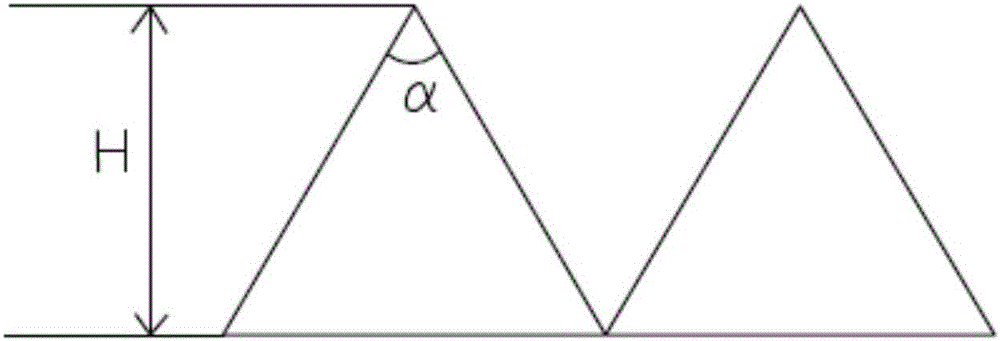

[0041] Coating acrylate (coating A) on the first barrier film, and embossing a microstructure (microstructure height 100um, apex angle 90 degrees) on the mold wheel with microstructure, and curing with UV lamp.

[0042] The quantum dot layer (coating B) is coated on the second barrier film, and the first semi-curing is performed with a UV light source.

[0043] The quantum dot film can be completed by laminating the first barrier film with a microstructure and the semi-cured second barrier film, and curing the second time with a UV lamp.

[0044] Paint A:

[0045] 17% by weight of acrylate SR339, 80% by weight of SR348 (purchased from Satomer Company), and 3% by weight of photoinitiator Irgacure 184 (purchased from Ciba Company) were uniformly mixed.

[0046] Paint B:

[0047] Mix 70% by weight of coating A with 30% by weight of quantum dot concentrate,

[0048] The quantum dot concentrate contains 85% by weight of a bifunctional amine hardener (purchased from Epic Resins) ...

Embodiment 2

[0050] Coating acrylate (coating A) on the first barrier film, and embossing the microstructure (microstructure height 100um, apex angle 90 degrees) on the mold wheel with microstructure, curing with UV lamp.

[0051] The quantum dot layer (coating C) was coated on the second barrier film, and the acrylate was cured with a UV light source.

[0052] Laminate the first barrier film with the microstructure and the second barrier film, and perform the second curing at a temperature of 105° C. for 5 minutes to complete the quantum dot film.

[0053] Paint C:

[0054]52% by weight of epoxy resin EPON 824 (purchased from Momentive Company), 15% by weight of acrylate SR348, 30% by weight of quantum dot concentrate, and 3% by weight of photoinitiator Irgacure 184 are mixed. The dot concentrate contained 85% by weight of a difunctional amine hardener (purchased from Epic Resins) and 15% by weight of quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com