Attitude-orbit integrated control oriented multi-execution mechanism cooperative control distribution method

A technology with multiple actuators and distribution methods, applied in attitude control, non-electric variable control, control/regulation systems, etc., can solve the problems of less mutual cooperation and low fuel usage of thrusters, and achieve improved use efficiency and good expansion Effects on sex and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

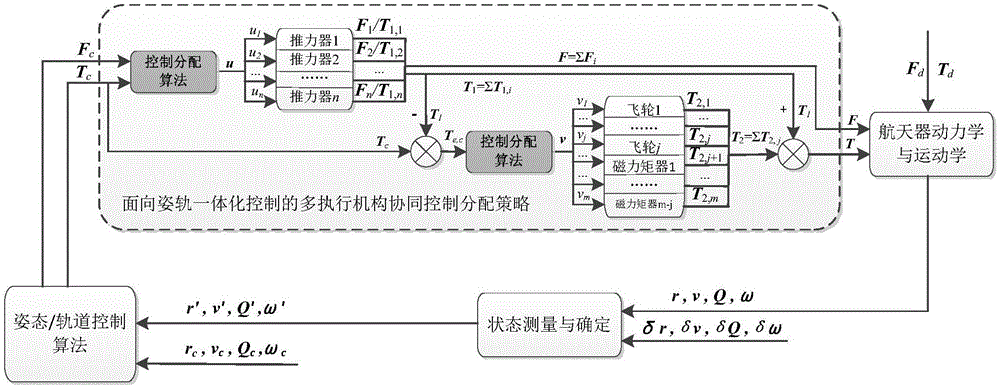

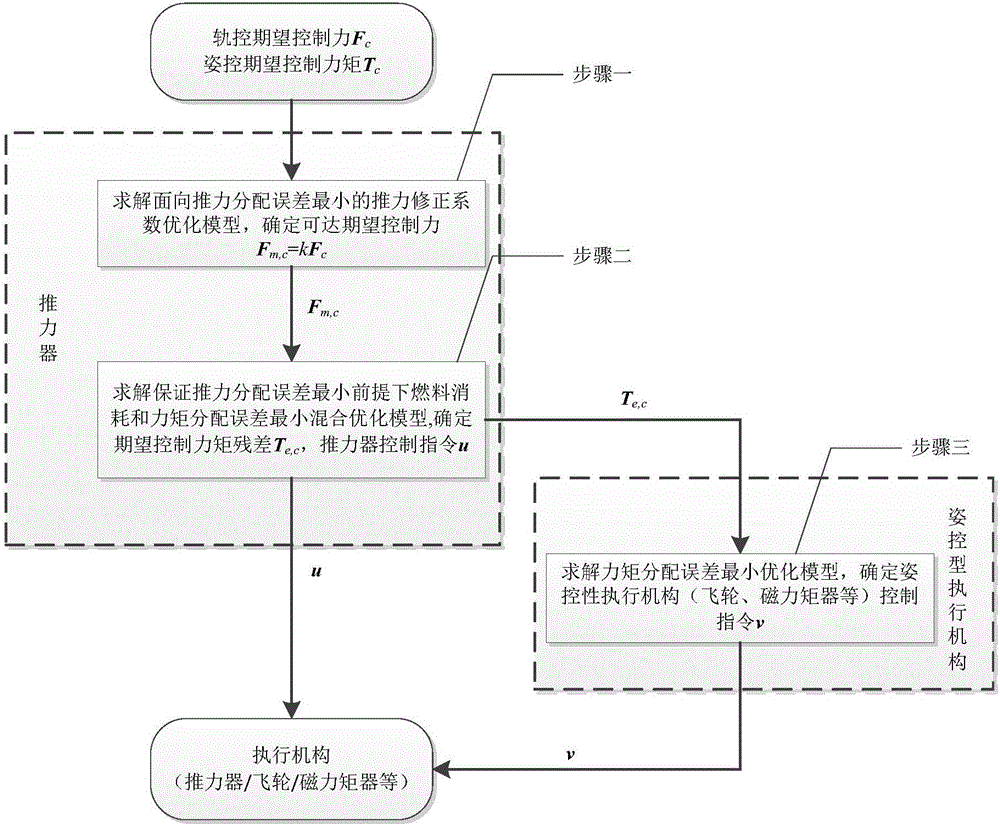

[0018] Specific implementation mode one: as figure 1 and figure 2 As shown, a multi-actuator cooperative control distribution method for integrated control of attitude and orbit includes the following steps:

[0019] Step 1: According to the desired control force F c , using the thrust correction coefficient optimization model oriented to the minimum thrust distribution error, transform the thrust correction coefficient optimization model into a standard linear programming model, solve the desired thrust correction factor k, and calculate the output desired control force F m,c ;

[0020] Among them, the expected thrust correction factor k is to correct the expected thrust when the expected control quantity exceeds the output capability range of the actuator.

[0021] f m,c = kF c (16)

[0022] Step 2: For the thruster, control the torque T according to the expectation c and the output expected control force F obtained in step 1 m,c , using the hybrid optimization mod...

specific Embodiment approach 2

[0030] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the thrust correction coefficient optimization model in the step one is specifically:

[0031] Min J=-k (1)

[0032] St.Bu=kF c (2)

[0033] u i,min i i,max ,i=1,2,...,n (3)

[0034] where u i is the i-th thruster, n is the number of thrusters (representing a matrix with n columns), k is the thrust correction coefficient, B is the thrust control efficiency matrix of the thruster, u is the control command of the thruster, and J is the objective function.

[0035] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

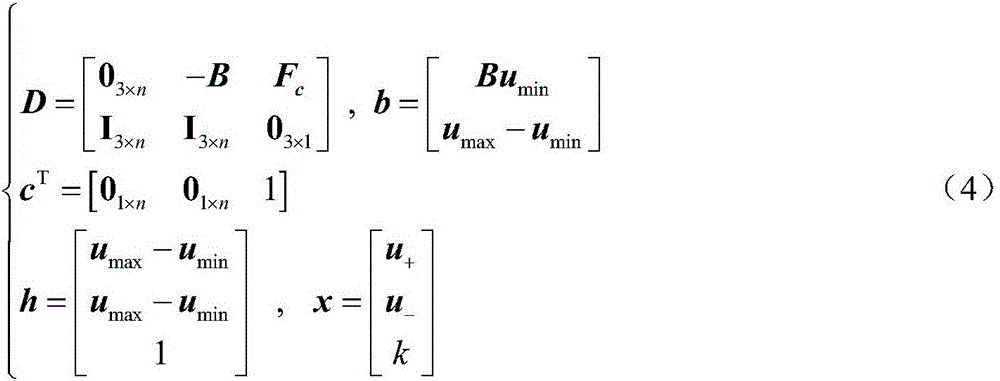

[0036] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: in the step one, the specific form of converting the thrust correction coefficient optimization model into a standard linear programming model is:

[0037] D = D 3 × n - B F c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com